-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Understanding Different Discount Options for Thread Rolling Machines

Understanding Discount Types for Thread Rolling Machines

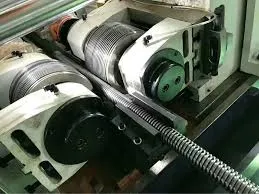

Thread rolling machines are essential tools in various manufacturing sectors, particularly in producing bolts, screws, and other threaded components. These machines offer a method of forming threads through a process of cold working, which can result in stronger threads compared to cutting methods. With various types of thread rolling machines available in the market, understanding the different discount types associated with them can help manufacturers make informed purchasing decisions.

Types of Thread Rolling Machines

Before diving into discount types, it is essential to understand the different thread rolling machines available

1. Flat Die Thread Rollers These machines use flat dies to create threads. They are typically used for larger production runs and are known for their efficiency.

2. Circular Thread Rollers Utilized for smaller products, circular rollers enable the creation of threads on round or cylindrical parts and are best for high precision threading.

3. Multi-Station Rollers Multi-station machines can perform several threading operations simultaneously, allowing for greater speed and efficiency in production environments.

4. Vertical Rollers These machines operate with the workpiece positioned vertically, which can provide advantages in certain applications, particularly for larger components.

Discount Types for Thread Rolling Machines

When purchasing thread rolling machines, buyers may encounter various forms of discounts

. Understanding these can facilitate cost savings and better investment decisionsdiscount types of thread rolling machine

1. Volume Discounts Manufacturers often provide discounts when customers order multiple machines or components at once. This is particularly beneficial for companies that require several machines to meet production needs, resulting in lower costs per unit.

2. Seasonal Discounts Many suppliers offer seasonal promotions or discounts during specific times of the year. For instance, during the end of the fiscal year or major industrial exhibitions, companies may provide significant price reductions.

3. Contractual Discounts Long-term contracts with suppliers can lead to favorable pricing. Companies that commit to purchasing specific types or brands of machines for extended periods can negotiate better rates.

4. Loyalty Discounts Existing customers often receive loyalty discounts, which reward them for repeat business. These discounts can apply to future purchases or service packages.

5. Promotional Discounts New products or updated models may be introduced with promotional pricing strategies to encourage early adoption of the latest technology.

6. Trade-in Discounts Some manufacturers may offer trade-in discounts for old machines when customers upgrade to newer models. This can significantly lower the price paid for advanced units.

Conclusion

Acquiring thread rolling machines is a substantial investment for manufacturers and businesses involved in production. By recognizing the various types of discounts available, buyers can optimize their purchasing strategies and reduce overall costs. Whether through volume discounts, seasonal offers, or loyalty incentives, understanding these opportunities can result in significant savings.

Moreover, it pays to conduct thorough research on different suppliers and the types of offers they provide. Negotiating directly with manufacturers and being aware of market trends can enhance the chances of securing favorable pricing. As the industry continues to evolve with advancements in technology and increasing demand for high-quality threaded components, leveraging discount strategies becomes a crucial component of effective procurement planning.

Investing in a thread rolling machine is not just about the initial cost but also about understanding the potential for long-term financial benefits through strategic purchasing. The right machine, acquired at the right price, can enhance production efficiency, reduce material waste, and ultimately lead to greater profitability for manufacturing businesses.