-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

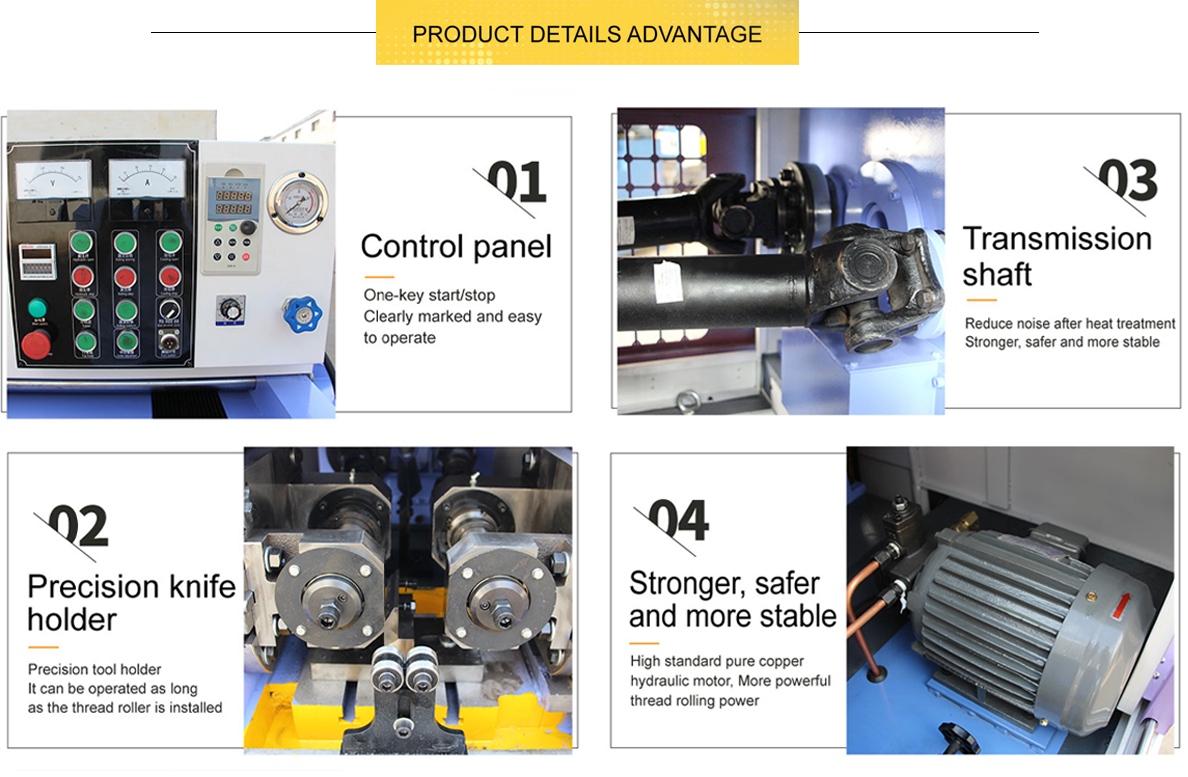

Exploring Various Manufacturers of Thread Rolling Machines for Different Applications

Types of Thread Rolling Machine Manufacturers

Thread rolling is a crucial machining process that transforms a plain cylindrical surface into a threaded one, commonly used in various industries such as automotive, aerospace, and manufacturing. The process provides several advantages over traditional thread cutting methods, including enhanced durability, improved surface finish, and greater dimensional accuracy. As industries demand high-quality threaded components, the need for thread rolling machines has surged. This article will explore the different types of thread rolling machine manufacturers and the innovations they are bringing to the market.

1. Types of Thread Rolling Machines

There are primarily three types of thread rolling machines flat die, cylindrical die, and planetary rolling machines. Each of these machine types serves specific applications and has unique characteristics.

- Flat Die Thread Rolling Machines These machines use two flat dies to roll the material into a desired thread profile. They are best suited for producing small to medium-sized threaded components, and manufacturers often use them for simpler threads such as those found in bolts and knobs. Flat die machines are known for their versatility and efficiency, making them a popular choice among manufacturers.

- Cylindrical Die Thread Rolling Machines These machines use two cylindrical dies that rotate over the workpiece to create threads. They are designed for high-volume production and are ideal for producing long and complex threaded components. Cylindrical die machines are particularly effective in high-speed applications, yielding rapid production rates while maintaining precision.

- Planetary Thread Rolling Machines These advanced machines offer a more complex motion that enables the production of different thread profiles and sizes. They utilize a planetary gear mechanism, allowing the workpiece to rotate while the rollers apply pressure, creating multiple threads at once. Planetary machines are preferred for producing high-strength parts and are efficient for manufacturing large quantities of components.

2. Leading Manufacturers in the Market

types of thread rolling machine manufacturer

Numerous manufacturers are leading the thread rolling machine market, each contributing unique innovations and technologies. Some of the prominent manufacturers include

- Meyer Burger Technology AG Known for its Swiss precision engineering, Meyer Burger specializes in high-performance thread rolling machines designed for efficiency and accuracy. Their machines often incorporate advanced CNC technology, allowing for programmable operations and quicker setup times.

- Greenerd Press & Machine Co., Inc. With a history dating back to the 19th century, Greenerd focuses on producing robust thread rolling machines that cater to a variety of industries. Their machines are renowned for durability and reliability, making them a favored choice among manufacturers.

- OUIKA Machine Tools Co., Ltd. This Chinese manufacturer is gaining traction in the global market, offering competitive prices and versatile machine options. OUIKA focuses on innovation and customization to meet the diverse needs of its clients.

3. Technological Innovations in Thread Rolling

The majority of contemporary thread rolling machine manufacturers are investing in technological advancements such as automation, IoT integration, and improved materials. By incorporating automation, manufacturers enhance their productivity and reduce labor costs. The introduction of IoT and smart technology allows machines to collect and analyze data in real-time, providing insights into performance and maintenance needs.

Conclusion

The thread rolling machine industry is evolving, thanks to the concerted efforts of various manufacturers to innovate and improve technology. With different types of machines available, companies can select the perfect fit for their specific applications. As market demands continue to evolve, the emphasis on high-quality, efficient, and precise thread rolling machines will only grow stronger, promising a bright future for this manufacturing sector. As manufacturers push the boundaries of technology, they play a pivotal role in shaping the production landscape across multiple industries.