-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exporter of Flat Die Thread Rolling Machines for Efficient Precision Manufacturing Solutions

Understanding Flat Die Thread Rolling Machines and Their Export Trends

In the world of manufacturing, thread rolling is a crucial process for producing strong, durable threads on various metal components. Among the different thread rolling machines available, flat die thread rolling machines have gained popularity due to their efficiency, precision, and versatility. This article delves into the characteristics of flat die thread rolling machines, their applications, and the trends in their export to different markets around the globe.

What is a Flat Die Thread Rolling Machine?

Flat die thread rolling machines are specialized machines that utilize two flat dies to shape the threads on a cylindrical workpiece. Unlike traditional cutting methods that remove material to create threads, thread rolling deforms the material, inherently strengthening the threads because of the grain flow alignment in the rolled area. This method not only enhances the mechanical properties of the threads but also improves surface finish, making it ideal for various applications in automotive, aerospace, and general manufacturing.

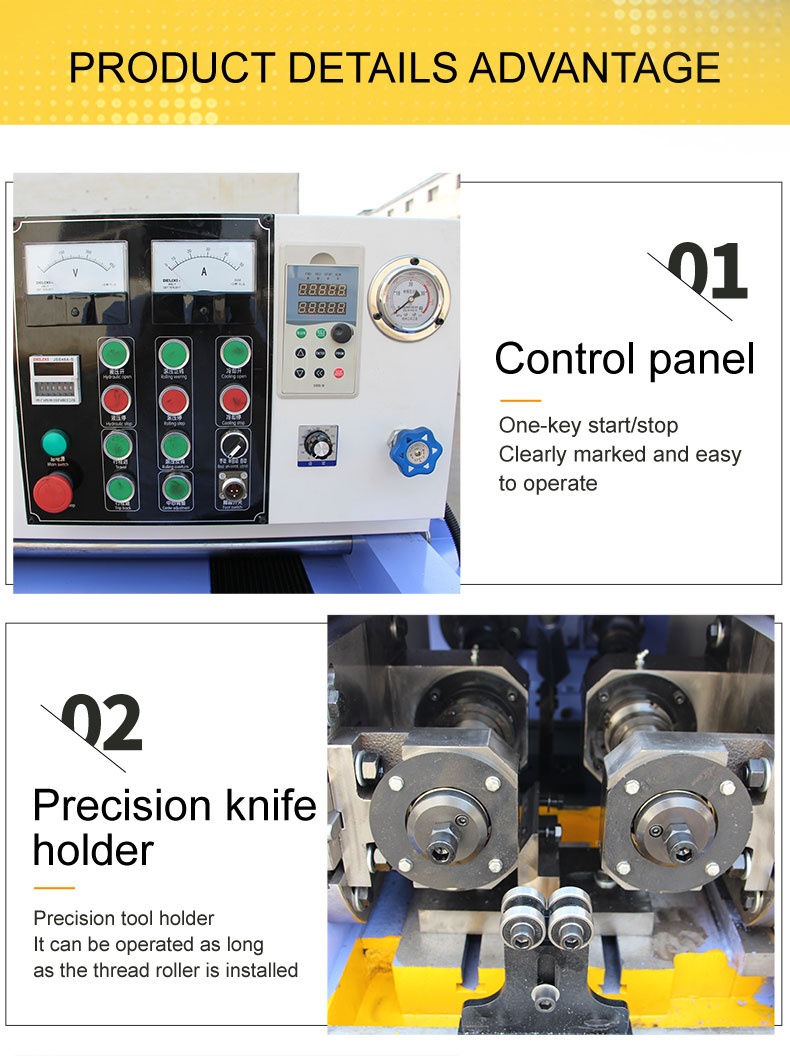

Key Features of Flat Die Thread Rolling Machines

1. High Precision These machines are designed to maintain tight tolerances, ensuring that the threads produced meet stringent specifications. This precision is crucial in high-stress applications where failures can have catastrophic consequences.

2. Efficiency Flat die thread rolling machines can operate at high speeds, allowing manufacturers to produce large quantities of threaded components in a shorter time. This efficiency translates into lower production costs and a competitive edge in the market.

3. Versatility They can accommodate a wide range of materials including steel, aluminum, and alloys, making them suitable for various industries. Additionally, the ability to adjust die configurations means that manufacturers can produce different thread sizes and profiles with ease.

flat die thread rolling machine exporter

4. Eco-Friendliness Since thread rolling does not cut away material but instead reshapes it, there is significantly less waste generated in the process. This feature aligns with the growing trend towards sustainability in manufacturing.

Global Export Trends

The demand for flat die thread rolling machines has been increasing globally as industries seek to enhance productivity and quality. Countries known for automotive and aerospace manufacturing, such as Germany, Japan, and the United States, are significant consumers of these machines. Furthermore, emerging economies in Asia, particularly India and China, are witnessing rapid industrialization, leading to an uptick in the demand for advanced manufacturing equipment including thread rolling machines.

Exporters of flat die thread rolling machines are adopting innovative strategies to cater to these markets. For instance, many are focusing on customization options to meet specific industry standards and regulations, thus attracting a wider client base. Additionally, there is a notable shift towards incorporating advanced technology such as automation and digital monitoring systems, which enhance the functionalities of traditional thread rolling machines.

Challenges in Exporting Flat Die Thread Rolling Machines

Despite the growing market for flat die thread rolling machines, exporters face several challenges. Tariffs and trade regulations can impact pricing and competitiveness in foreign markets. Additionally, the need for after-sales support and training is crucial, as different markets may have varying levels of expertise in using these machines. Exporters must also ensure compliance with international standards to gain and maintain the trust of global clients.

Conclusion

Flat die thread rolling machines represent a vital segment of the manufacturing sector, offering tools that combine efficiency with precision. The increasing demand for these machines reflects broader trends in manufacturing aimed at achieving higher productivity and quality. As the global market continues to evolve, exporters of flat die thread rolling machines must navigate challenges while capitalizing on opportunities to innovate and expand their offerings. A forward-thinking approach will not only enable suppliers to thrive but also contribute to the enhancement of manufacturing practices worldwide.