-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

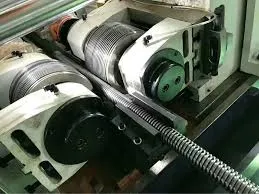

Innovative Flat Die Thread Rolling Machines for Precision Manufacturing Solutions

The Evolution and Importance of the Flat Die Thread Rolling Machine

In the vast landscape of manufacturing and metalworking, the flat die thread rolling machine stands out as a pivotal technology that has significantly transformed the production of threaded fasteners. This machine is essential for creating high-precision threads on various materials, making it a staple in industries ranging from automotive to aerospace.

The Fundamentals of Flat Die Thread Rolling

At its core, the flat die thread rolling machine employs a cold forming process that reshapes the material into threads without removing any material. Instead of cutting or grinding, this method displaces the metal fibers to form the desired thread profile. The rolling is performed between two flat dies, which are precisely engineered to create the specific thread dimensions required. This process not only enhances the strength and integrity of the threads but also improves surface finish and reduces machining time.

Design and Mechanism

The flat die thread rolling machine typically consists of several key components the feed mechanism, the die holders, and the drive system. The feed mechanism advances the workpiece into the rolling dies, where the actual thread formation occurs. The die holders are precisely adjustable to accommodate different thread sizes and pitches. The drive system, usually powered by electric motors, generates the necessary speed and torque to ensure efficient rolling.

One of the significant advantages of flat die thread rolling machines is their ability to produce high volumes of consistent, high-quality threads. This consistency is crucial in applications where precise tolerances are required, such as in manufacturing bolts, screws, and other threaded fasteners.

Advantages of Using Flat Die Thread Rolling Machines

1. Enhanced Strength The cold rolling process increases the density of the material, which contributes to the overall strength of the threaded component. Threads produced through this method are less likely to become weak or fracture under stress.

famous flat die thread rolling machine

2. Cost Efficiency By eliminating the need for cutting tools and reducing waste material, flat die thread rolling can lower production costs. The quick cycle times associated with this process further enhance profitability.

3. Improved Surface Finish Cold rolling not only shapes the thread but also enhances the surface finish compared to traditional machining methods. This leads to improved performance and lower friction in applications where threaded components are subjected to dynamic loads.

4. Versatility Flat die thread rolling machines can accommodate various materials, including steel, aluminum, brass, and even plastics. This versatility allows manufacturers to adapt to different production requirements and handle a wide range of products.

The Future of Thread Rolling Technology

As industries continue to evolve, the demand for precision-engineered components increases. Advances in technology are likely to lead to further improvements in flat die thread rolling machines. Incorporating automation, digital control systems, and real-time monitoring can optimize the production process, enhance quality control, and reduce downtime.

Moreover, as sustainability becomes an essential factor in manufacturing, flat die thread rolling could play a vital role in reducing waste and energy consumption compared to traditional machining methods. Manufacturers are expected to invest in energy-efficient machinery that aligns with green manufacturing practices.

Conclusion

The flat die thread rolling machine is an indispensable tool in modern manufacturing, combining efficiency, precision, and versatility. As technology continues to advance, this machinery will likely evolve, driving innovation and maintaining its crucial role in the production of high-quality threaded fasteners. With its numerous advantages, the flat die thread rolling process is poised to remain at the forefront of the metalworking industry for years to come.