-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

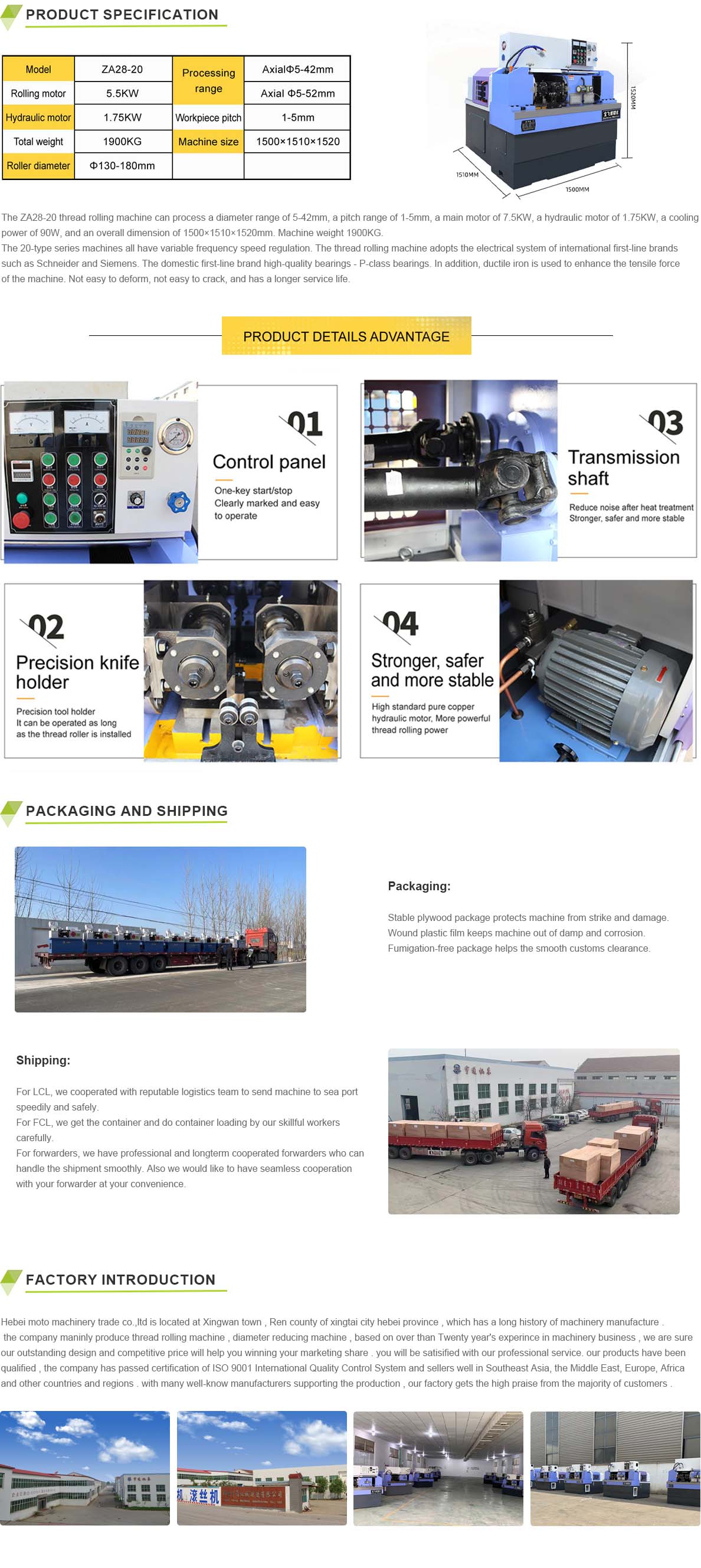

Innovative High-Speed Thread Rolling Machines for Efficient Production Processes

The Evolution and Importance of High-Speed Thread Rolling Machines

In the world of manufacturing, precision and efficiency are paramount. Among the myriad of techniques employed to produce high-quality threaded components, high-speed thread rolling machines stand out due to their remarkable ability to generate threads rapidly while maintaining exceptional accuracy. This article explores the significance, functionality, and advancements of high-speed thread rolling machines in modern manufacturing.

Understanding Thread Rolling

Thread rolling is a cold-forming process that involves the creation of threads through the deformation of material. Unlike other methods such as cutting or grinding, thread rolling preserves the material’s microstructure, leading to enhanced mechanical properties. High-speed thread rolling machines perform this operation using specially designed dies, which press a workpiece between them, forming the required threads through compressive force.

The Benefits of High-Speed Thread Rolling Machines

1. Increased Production Rates One of the primary advantages of high-speed thread rolling machines is their ability to produce threads at much higher speeds compared to traditional methods. This efficiency is crucial in high-volume production environments, such as the automotive and aerospace industries, where timely delivery of components is essential.

2. Quality and Precision High-speed machines are engineered to maintain tight tolerances and high-accuracy threading. The cold-forming process reduces the risk of defects commonly associated with machining, such as burrs and micro-cracking. Consequently, parts produced via thread rolling often display superior surface finishes and dimensional consistency.

3. Material Savings By using the cold-forming method, manufacturers experience minimal material wastage. The process not only shapes the thread but also enhances the material's density, strength, and fatigue resistance, allowing for the production of lighter yet robust components.

famous high speed thread rolling machine

4. Versatility Modern high-speed thread rolling machines can accommodate a range of materials, including steel, aluminum, and brass. They are capable of producing various thread profiles and sizes, making them suitable for diverse applications in industries such as electronics, construction, and medical devices.

Technological Advancements

The evolution of high-speed thread rolling machines has been marked by innovations that enhance their functionality further. Recent advancements include

- Automated Controls The integration of advanced control systems allows for greater automation in thread rolling processes. Automated machines minimize human intervention, thereby reducing the potential for errors and maximizing production efficiency.

- Smart Technology Incorporating IoT (Internet of Things) technology enables manufacturers to monitor machine performance in real-time, predicting maintenance needs and reducing downtime. Data analytics can also help optimize production parameters for improved output.

- Energy Efficiency New designs focus on energy-efficient operations, reducing operational costs and environmental impacts. These machines often come equipped with energy recovery systems that recycle energy, making them more sustainable choices for manufacturers.

Conclusion

High-speed thread rolling machines are a cornerstone of modern manufacturing, providing a combination of speed, precision, and cost-efficiency that traditional machining methods often cannot match. As industries continue to demand high-quality threaded components in shorter lead times, the role of these machines becomes increasingly critical. Embracing technological advancements will only enhance their capabilities further, ensuring that they remain indispensable tools in the quest for manufacturing excellence. As we look to the future, the commitment to innovation in high-speed thread rolling technology will undoubtedly shape the landscape of manufacturing, driving efficiency and quality to unprecedented heights.