-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

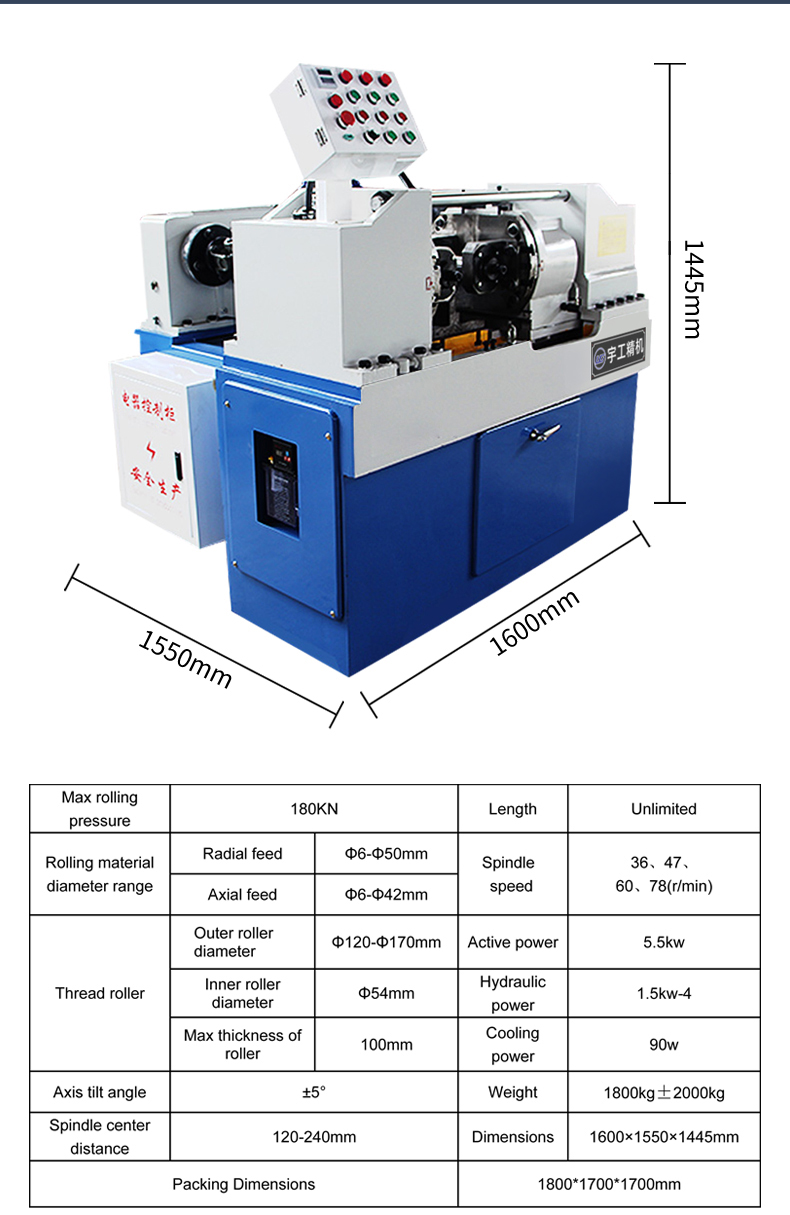

Innovative Hydraulic Machines for Precision Thread Rolling Applications and Efficiency

The Importance of Hydraulic Thread Rolling Machines in Modern Manufacturing

In the realm of modern manufacturing, efficiency and precision are paramount. One of the key technologies that has evolved to meet these demands is the hydraulic thread rolling machine. This equipment finds extensive application in various industries, from automotive to aerospace, and even in the production of intricate machinery components. In this article, we will explore what hydraulic thread rolling machines are, how they operate, and their significance in contemporary manufacturing processes.

Understanding Hydraulic Thread Rolling Machines

Hydraulic thread rolling machines utilize the unique process of thread rolling to create threaded components with high accuracy and superior surface finishes. Unlike traditional cutting methods, which remove material to generate threads, thread rolling is a cold working process. It deforms the material without cutting, allowing manufacturers to produce threads that are often stronger and more robust. This is particularly important in industries where durability is crucial.

The core of a hydraulic thread rolling machine is its hydraulic system, which provides the necessary force to roll the threads into the material. By using hydraulic pressure instead of mechanical means, these machines can achieve higher force levels and maintain consistent performance over extended periods. This leads to increased productivity and reduced wear and tear on the equipment.

How It Works

The process typically begins with a workpiece, which is usually a metal rod. The rod is placed between two or more rotating rollers, each equipped with a specific thread profile. As the rollers move closer together, they exert pressure on the rod, causing it to deform and take on the desired thread shape. The hydraulic system ensures that the rollers maintain the correct pressure and alignment throughout the threading process.

One of the significant advantages of this technique is that it allows for the creation of multiple threads simultaneously, thereby increasing output. Additionally, because there is no material removal, the process generates less waste, making it a more sustainable option compared to conventional machining.

famous hydraulic thread rolling machine

Advantages of Hydraulic Thread Rolling Machines

1. Enhanced Strength Components produced through thread rolling exhibit superior tensile strength due to the work-hardening effect associated with the cold working process. This is especially beneficial in applications where strength and reliability are critical.

2. Excellent Surface Finishes The thread rolling process results in a smooth surface finish, reducing the need for additional machining or finishing operations. This not only saves time but also reduces costs associated with secondary processes.

3. Higher Production Rates Hydraulic thread rolling machines can operate at high speeds, significantly improving production rates. This makes them ideal for high-volume manufacturing settings.

4. Versatility These machines can be adapted to produce various thread forms and sizes, accommodating a wide range of applications. This versatility allows manufacturers to meet the diverse needs of their customers without significant adjustments to their equipment.

5. Cost-Effectiveness With lower energy consumption and less material waste, hydraulic thread rolling machines can lead to optimized production costs over time.

Conclusion

As industries continue to push the boundaries of efficiency and quality, hydraulic thread rolling machines stand out as a vital technology in the manufacturing landscape. Their ability to produce strong, precise threaded components quickly and efficiently has made them invaluable in numerous sectors. Investing in modern hydraulic thread rolling technology is essential for manufacturers looking to enhance their competitiveness and improve product quality. As we move forward, the role of these machines will only become more significant, driving innovation and excellence in manufacturing practices around the globe.