-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

famous thread rolling machine

The Evolution and Importance of Famous Thread Rolling Machines

In the world of manufacturing and industrial processes, thread rolling machines stand as a pivotal technology that has evolved significantly over the years. Their importance in producing high-quality threaded fasteners and components cannot be overstated. From their early mechanical designs to the advanced computerized systems used today, thread rolling machines have revolutionized how manufacturers approach the creation of threaded elements.

Understanding Thread Rolling

Thread rolling is a cold-forming process that creates threads on a workpiece by deforming the material with specially designed dies. Unlike traditional cutting methods, thread rolling does not remove material; instead, it displaces it, resulting in a stronger and more resilient thread. This process is favored for several reasons it improves the tensile strength of the threaded material, enhances surface finish, and reduces the overall production time.

The design of thread rolling machines has seen remarkable advancements. Early machines were essentially mechanical devices operated manually. They required significant labor and precision to ensure quality and accuracy. However, with the advent of technology, the transition to automatic and CNC (Computer Numerical Control) machines has improved production efficiency manifold. Modern thread rolling machines can produce consistent and high-quality threads at an impressive rate, making them essential in industries ranging from automotive to aerospace.

Key Features of Modern Thread Rolling Machines

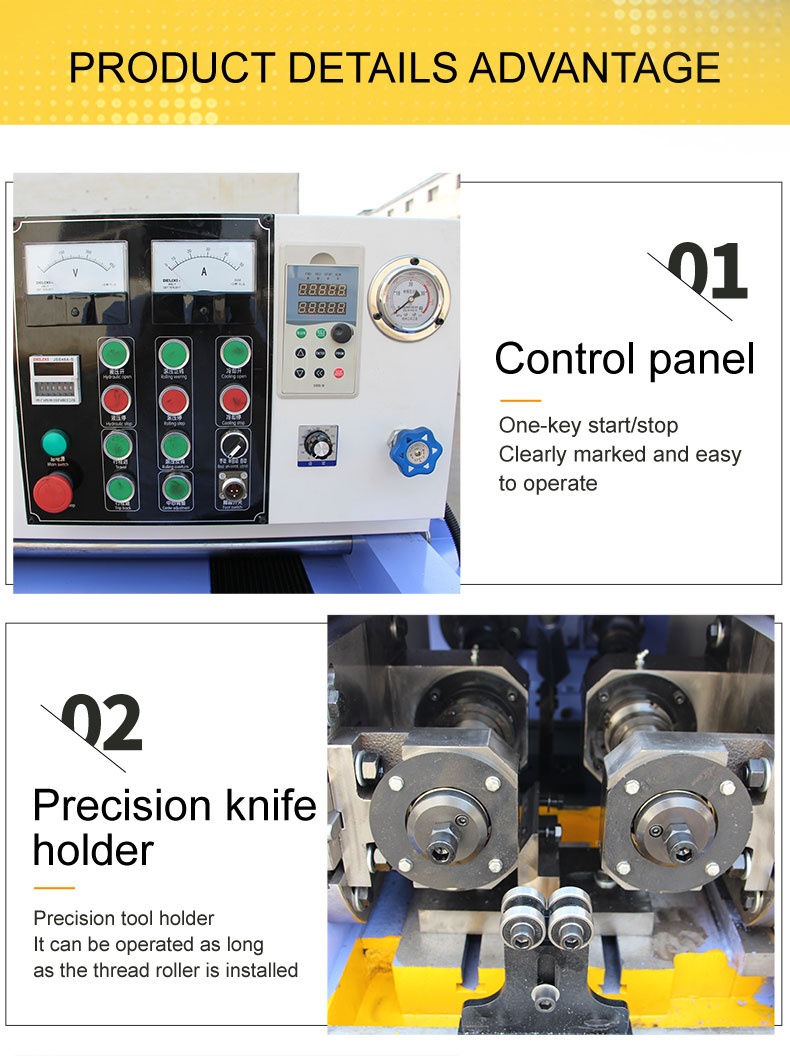

1. Precision Engineering Today's thread rolling machines utilize advanced engineering principles to achieve superior accuracy. The design of rolling dies is critical, as they must match the desired thread form precisely. The integration of CNC technology allows for quick adjustments, catering to different specifications without extensive downtime.

2. Increased Production Speed The automation of thread rolling machines has led to more streamlined production processes. Modern machines can roll threads at higher speeds while maintaining exceptional quality, significantly enhancing production capacity.

3. Versatility Advanced thread rolling machines can work with various materials, including steel, aluminum, and various alloys. This versatility allows manufacturers to cater to a wide range of industries and applications, making them indispensable in modern production environments.

famous thread rolling machine

4. Enhanced Operator Safety The adoption of safety features in modern machines has been a significant development. Enclosed systems, emergency stop features, and automated handling systems minimize the risk of accidents and ensure a safer working environment.

The Impact on Industries

The implications of thread rolling machines extend beyond their technical capabilities. These machines have a profound impact on multiple sectors, including

- Automotive Industry High-strength fasteners are crucial for ensuring vehicles' safety and performance. Thread rolling machines are used extensively to manufacture components that meet stringent safety standards.

- Aerospace Given the criticality of structural integrity in aerospace applications, the reliability of fasteners produced through thread rolling processes is paramount. These machines provide the precision and strength required for components that operate under extreme conditions.

- Construction The construction industry relies heavily on robust threading for various applications, from structural beams to framework supports. Thread rolling machines provide the high-quality threads necessary for these demanding applications.

Conclusion

Famous thread rolling machines have played an instrumental role in modern manufacturing, combining traditional craftsmanship with contemporary technology. As industries continue to evolve, the demand for high-quality, reliable threaded fasteners remains steady. The advancements in thread rolling technology reflect broader trends towards efficiency, safety, and precision in manufacturing processes.

In summary, the journey of thread rolling machines from manual operations to sophisticated automated systems highlights the importance of innovation in driving industrial growth. As we look to the future, these machines will undoubtedly continue to refine and redefine the standards of quality and efficiency in the manufacturing landscape, solidifying their status as a foundational element in producing essential components across various sectors.