-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

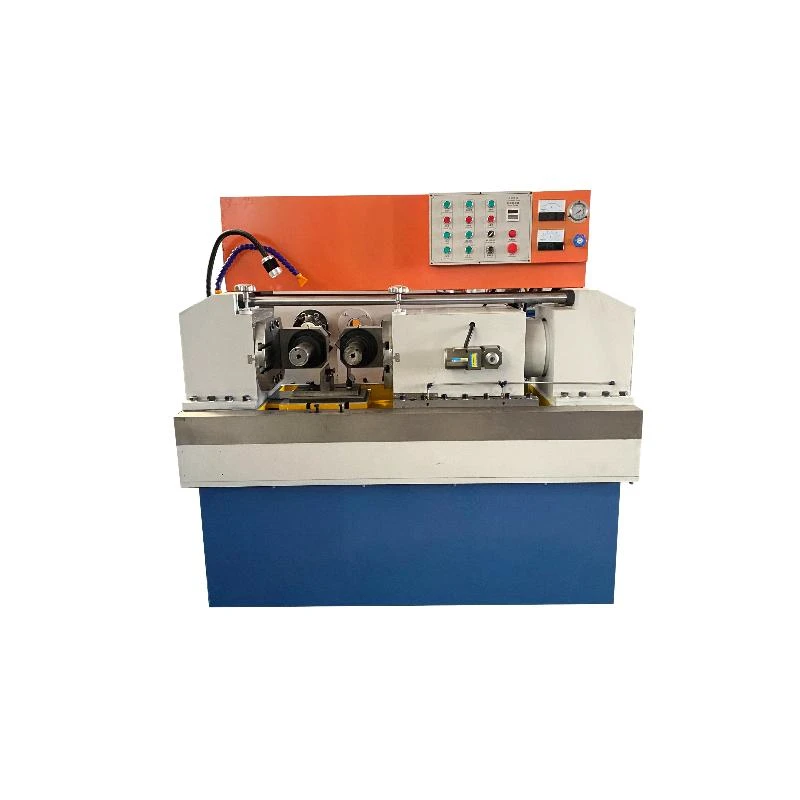

Price List for Popular Thread Rolling Machines in the Market Today

Understanding the Price List of Famous Thread Rolling Machines

In the world of manufacturing and metal fabrication, thread rolling machines play a pivotal role. They are essential for producing threads on various metal parts, providing superior strength and precision compared to traditional cutting methods. With the increasing demand for high-quality threaded components in various industries, the prices of thread rolling machines can vary widely based on several factors.

The Basics of Thread Rolling Machines

Thread rolling is a machining process that creates threads on a cylindrical part through the use of two or three rotating dies that deform the material. This method can be used on a wide range of materials, from soft metals to harder alloys. The advantages of thread rolling over traditional cutting methods include improved tensile strength of the threads, better surface finish, and higher production rates.

Factors Influencing the Price of Thread Rolling Machines

1. Machine Type There are different types of thread rolling machines, including flat die, cylindrical die, and planetary thread rolling machines. Each type has its unique applications, and this directly impacts pricing. For example, high-precision planetary machines tend to be more expensive due to their complexity and the quality of threads they produce.

2. Capacity and Size The size and capacity of the machine greatly influence its price. Larger machines that can handle bigger workpieces or higher production rates usually come with a higher price tag. Manufacturers often provide models that cater to different production needs, from small workshops to large-scale operations.

famous thread rolling machine price list

3. Brand Reputation Renowned manufacturers often charge a premium for their machines due to their established reputation for quality and reliability. Brands that are well-regarded in the industry tend to offer better customer support and warranty services, which can justify the higher cost.

4. Features and Technology Modern thread rolling machines are equipped with advanced features like programmable controls, automatic lubrication systems, and enhanced safety mechanisms. These technological advancements improve efficiency and ease of use but can also significantly increase the cost.

5. Market Demand and Location Prices can fluctuate based on regional demand and the availability of machinery. In regions with high industrial activity, machines may command higher prices due to increased competition among buyers.

Typical Price Ranges

While the prices for thread rolling machines can vary greatly, a general overview can be provided. Entry-level machines may start around $5,000, suitable for smaller operations or specific applications. Mid-range machines with better features and capabilities can range from $15,000 to $50,000. High-end, specialized machines intended for large-scale manufacturing can exceed $100,000.

Conclusion

Investing in a thread rolling machine is a crucial decision for manufacturers looking to enhance their production capabilities. Understanding the various factors that influence pricing can help buyers make informed decisions. It's essential to consider not just the initial cost but also the machine's efficiency, reliability, and the support provided by the manufacturer. By assessing these aspects, businesses can choose a machine that not only fits their budget but also meets their production needs effectively. As industries continue to evolve and the demand for high-quality threaded components increases, having the right thread rolling machine can serve as a substantial advantage in a competitive market.