-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Flat Die Thread Rolling Machine Price List and Purchasing Guide

The Flat Die Thread Rolling Machine An Overview and Price Insights

In the realm of manufacturing, thread rolling machines play a crucial role in efficiently producing threaded fasteners and components. Among the various types of these machines, the flat die thread rolling machine stands out for its versatility and efficiency. This article delves into the features, applications, and pricing trends associated with flat die thread rolling machines, providing potential buyers with valuable information.

What is a Flat Die Thread Rolling Machine?

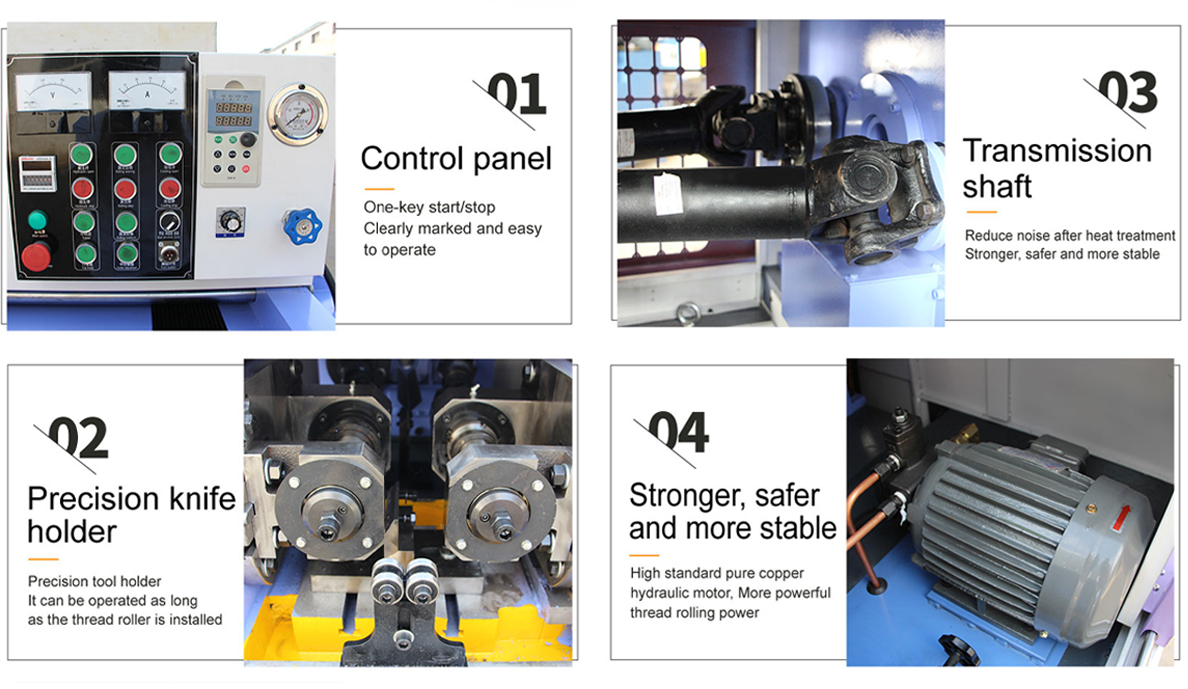

A flat die thread rolling machine is a piece of industrial equipment used to create threads on metal workpieces. It employs a pair of parallel flat dies, which impart the desired thread profile onto the material as it is fed through the machine. The process is cold forming, meaning it reshapes the metal without the use of heat, resulting in a stronger and more durable thread than those produced by cutting methods.

Benefits of Using Flat Die Thread Rolling Machines

1. High Efficiency These machines are known for their high production rates. They can produce large quantities of threaded components in a relatively short amount of time, making them suitable for high-volume manufacturing.

2. Quality and Precision The cold rolling process preserves the integrity of the metal, leading to tighter tolerances and less material waste. The resulting threads are often stronger and more consistent compared to those produced by traditional machining.

4. Versatility These machines can accommodate a wide range of materials, including carbon steel, stainless steel, and non-ferrous metals, making them adaptable to various manufacturing needs.

Applications

flat die thread rolling machine pricelist

Flat die thread rolling machines are widely used in various industries, including automotive, aerospace, construction, and electronics. They are commonly employed to manufacture components such as bolts, screws, and nuts that require precise and reliable threading. The ability to produce custom thread sizes and profiles adds to their appeal across different sectors.

Price Range and Market Trends

The pricing of flat die thread rolling machines can vary significantly based on several factors, including machine size, brand, and specific technological features. Generally, prices can range from a few thousand to several tens of thousands of dollars. For instance, small, entry-level machines suitable for light-duty applications may cost around $5,000 to $10,000. In contrast, high-capacity, advanced models designed for heavy-duty production can exceed $50,000.

Several market trends are influencing the pricing and demand for flat die thread rolling machines

1. Technological Advancements The introduction of automated and CNC-enabled machines is gradually reshaping the market, offering enhanced precision and reduced labor costs. As these advanced models become more common, traditional machines may see a shift in pricing dynamics.

2. Increased Demand for Customization As industries push for more customized fasteners, manufacturers are investing in flexible thread rolling machines that can accommodate varying specifications. This demand is driving innovation and can impact pricing.

3. Sustainability and Efficiency With a growing emphasis on sustainable manufacturing practices, machines that offer energy efficiency and minimal waste generation are becoming more desirable. Buyers may be willing to pay a premium for equipment that aligns with these values.

Conclusion

Flat die thread rolling machines are an indispensable asset in modern manufacturing, providing efficiency, versatility, and superior thread quality. As the industry evolves with new technologies and demands, understanding the pricing landscape becomes essential for businesses looking to invest in these machines. By considering the factors affecting prices and market trends, manufacturers can make informed decisions that align with their production needs and budget constraints.