-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jun . 30, 2024 12:20

Back to list

Flat Die Thread Rolling Machinery Advanced Products for Efficient Thread Formation

Understanding Flat Die Thread Rolling Machines A Comprehensive Overview

In the world of precision engineering, Flat Die Thread Rolling Machines occupy a pivotal role in the manufacturing process, particularly for producing high-quality threads on various materials. These innovative machines exemplify the perfect blend of efficiency, precision, and versatility, making them indispensable tools in industries ranging from automotive to aerospace.

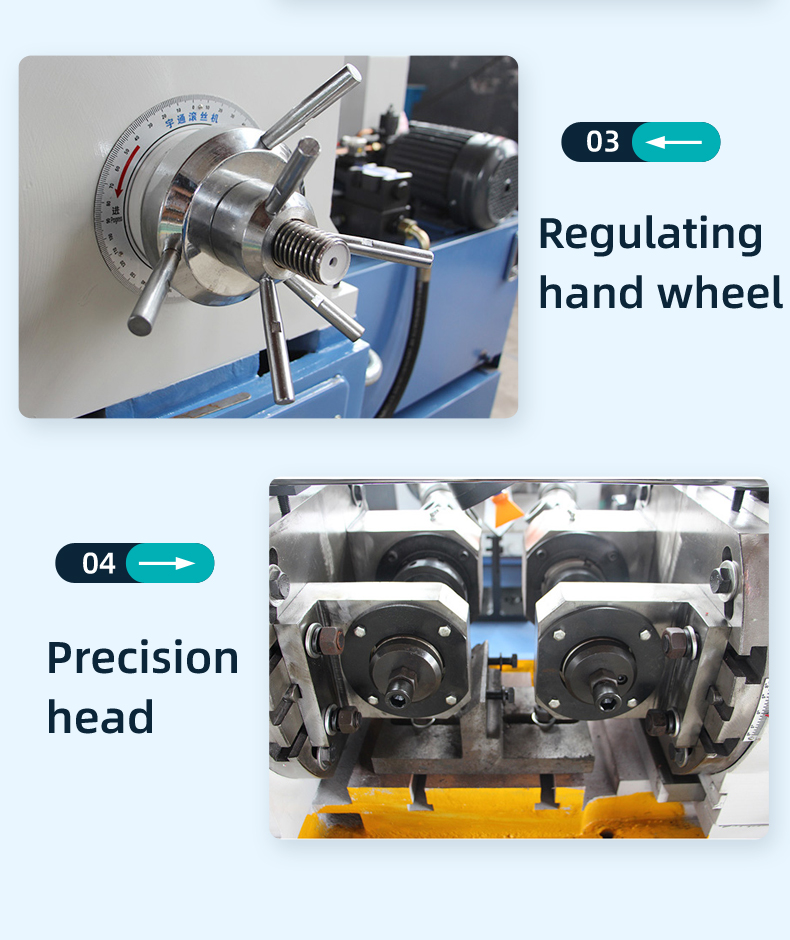

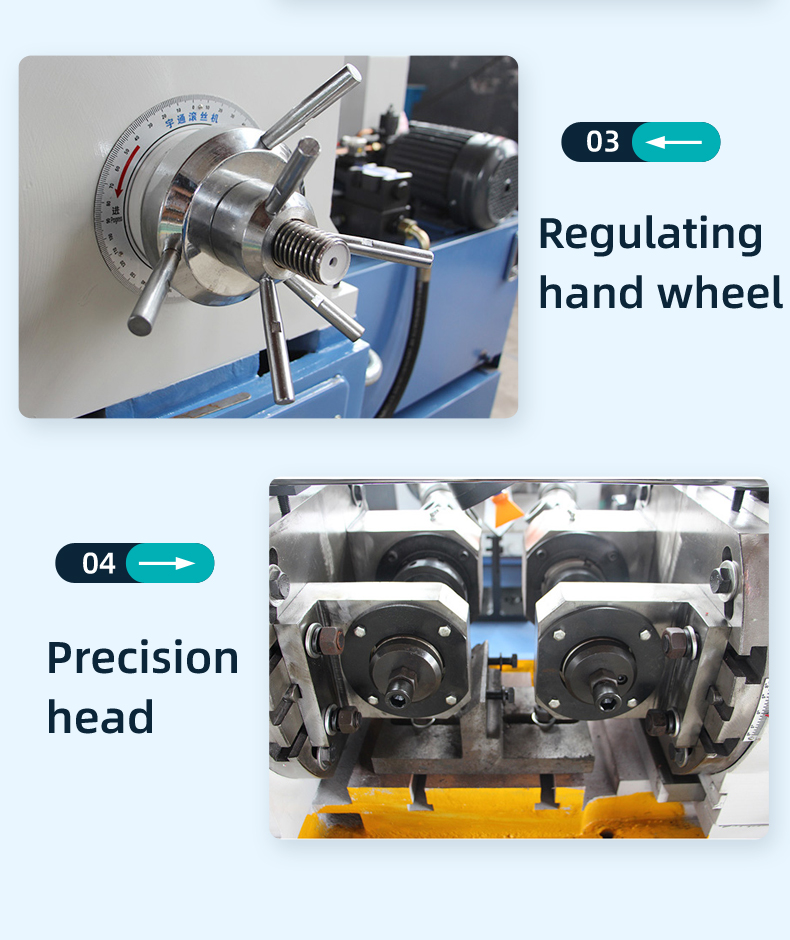

Flat die thread rolling machines are designed to shape or form threads on a workpiece by pressing it between two dies, which have the inverse profile of the desired thread. Unlike cutting processes that remove material, thread rolling is a cold-forming process, resulting in stronger threads with superior surface finish. The process is known for its ability to enhance the mechanical properties of the material, as it works the metal, increasing its density and hardness.

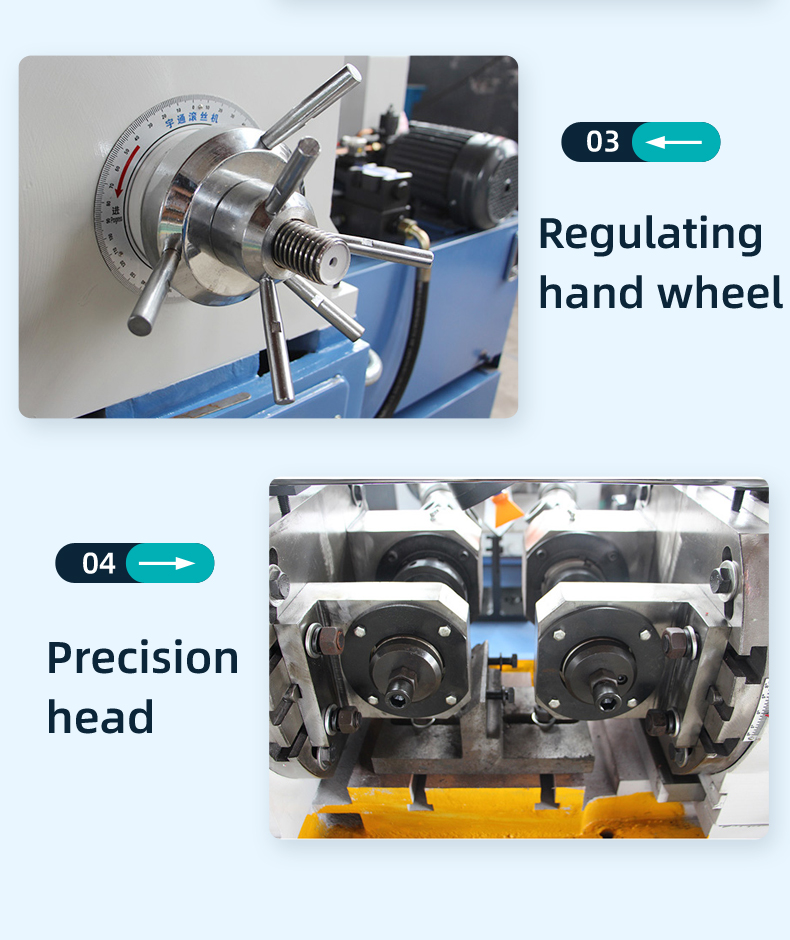

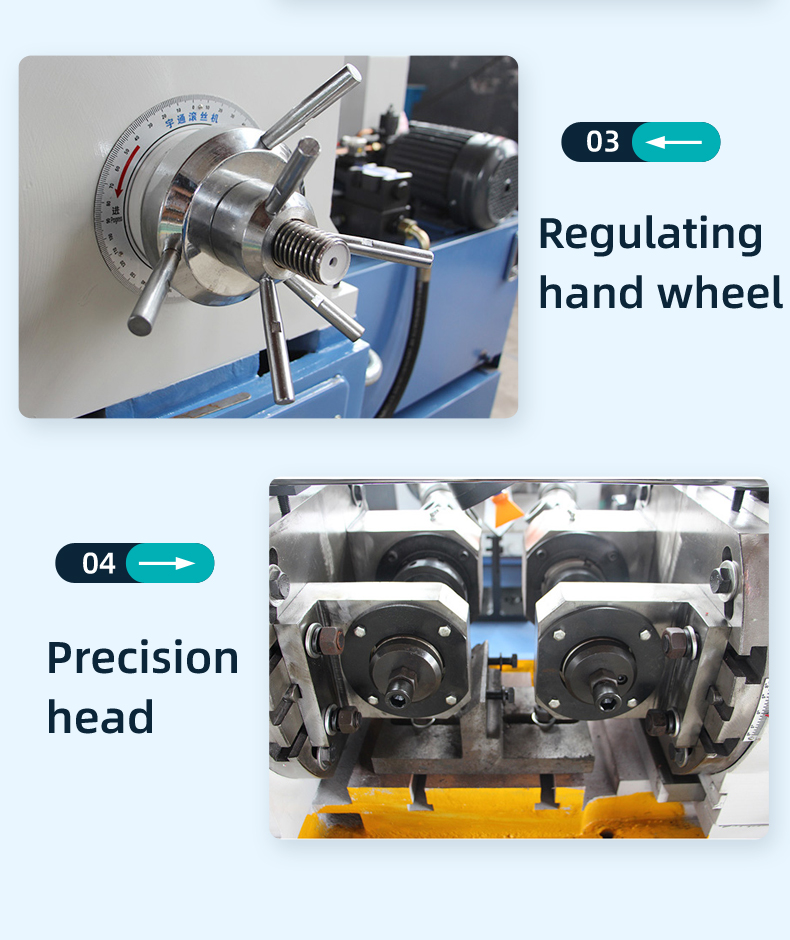

The primary advantage of flat die thread rolling machines lies in their ability to produce threads with exceptional accuracy and consistency. The dies used in these machines are precisely machined, ensuring that each thread produced is an exact replica of the die's profile. This level of precision is crucial in industries where tolerances are stringent and product reliability is paramount.

Flat die thread rolling machines come in various designs, catering to different production needs. Some models are manual, suitable for low-volume productions or prototyping, while others are fully automated, capable of high-speed, high-volume threading operations. Advanced models often incorporate CNC (Computer Numerical Control) systems, allowing for complex threading patterns and enhanced productivity through programmable settings Advanced models often incorporate CNC (Computer Numerical Control) systems, allowing for complex threading patterns and enhanced productivity through programmable settings Advanced models often incorporate CNC (Computer Numerical Control) systems, allowing for complex threading patterns and enhanced productivity through programmable settings Advanced models often incorporate CNC (Computer Numerical Control) systems, allowing for complex threading patterns and enhanced productivity through programmable settings

Advanced models often incorporate CNC (Computer Numerical Control) systems, allowing for complex threading patterns and enhanced productivity through programmable settings Advanced models often incorporate CNC (Computer Numerical Control) systems, allowing for complex threading patterns and enhanced productivity through programmable settings flat die thread rolling machine products.

These machines can handle a wide range of materials, from mild steel to stainless steel, aluminum, brass, and even exotic alloys. They are particularly effective in processing hard materials, as the cold-forming process does not require the same level of cutting force as traditional threading methods.

Moreover, the flat die thread rolling process generates minimal waste, reduces tool wear, and requires fewer setup changes compared to other threading techniques. It also offers a safer working environment, as the process typically produces less noise, vibration, and dust than cutting methods.

In conclusion, flat die thread rolling machines are more than just tools; they are precision-engineered solutions that elevate the quality and efficiency of thread production. Their adaptability, durability, and the superior threads they produce make them a staple in modern manufacturing facilities. As technology continues to advance, one can expect these machines to become even more sophisticated, further enhancing their capabilities and expanding their application scope. Whether in automotive bolts, aerospace components, or industrial machinery, flat die thread rolling machines remain an essential element in creating robust, reliable threads that withstand the test of time.

flat die thread rolling machine products.

These machines can handle a wide range of materials, from mild steel to stainless steel, aluminum, brass, and even exotic alloys. They are particularly effective in processing hard materials, as the cold-forming process does not require the same level of cutting force as traditional threading methods.

Moreover, the flat die thread rolling process generates minimal waste, reduces tool wear, and requires fewer setup changes compared to other threading techniques. It also offers a safer working environment, as the process typically produces less noise, vibration, and dust than cutting methods.

In conclusion, flat die thread rolling machines are more than just tools; they are precision-engineered solutions that elevate the quality and efficiency of thread production. Their adaptability, durability, and the superior threads they produce make them a staple in modern manufacturing facilities. As technology continues to advance, one can expect these machines to become even more sophisticated, further enhancing their capabilities and expanding their application scope. Whether in automotive bolts, aerospace components, or industrial machinery, flat die thread rolling machines remain an essential element in creating robust, reliable threads that withstand the test of time.

Advanced models often incorporate CNC (Computer Numerical Control) systems, allowing for complex threading patterns and enhanced productivity through programmable settings Advanced models often incorporate CNC (Computer Numerical Control) systems, allowing for complex threading patterns and enhanced productivity through programmable settings

Advanced models often incorporate CNC (Computer Numerical Control) systems, allowing for complex threading patterns and enhanced productivity through programmable settings Advanced models often incorporate CNC (Computer Numerical Control) systems, allowing for complex threading patterns and enhanced productivity through programmable settings flat die thread rolling machine products.

These machines can handle a wide range of materials, from mild steel to stainless steel, aluminum, brass, and even exotic alloys. They are particularly effective in processing hard materials, as the cold-forming process does not require the same level of cutting force as traditional threading methods.

Moreover, the flat die thread rolling process generates minimal waste, reduces tool wear, and requires fewer setup changes compared to other threading techniques. It also offers a safer working environment, as the process typically produces less noise, vibration, and dust than cutting methods.

In conclusion, flat die thread rolling machines are more than just tools; they are precision-engineered solutions that elevate the quality and efficiency of thread production. Their adaptability, durability, and the superior threads they produce make them a staple in modern manufacturing facilities. As technology continues to advance, one can expect these machines to become even more sophisticated, further enhancing their capabilities and expanding their application scope. Whether in automotive bolts, aerospace components, or industrial machinery, flat die thread rolling machines remain an essential element in creating robust, reliable threads that withstand the test of time.

flat die thread rolling machine products.

These machines can handle a wide range of materials, from mild steel to stainless steel, aluminum, brass, and even exotic alloys. They are particularly effective in processing hard materials, as the cold-forming process does not require the same level of cutting force as traditional threading methods.

Moreover, the flat die thread rolling process generates minimal waste, reduces tool wear, and requires fewer setup changes compared to other threading techniques. It also offers a safer working environment, as the process typically produces less noise, vibration, and dust than cutting methods.

In conclusion, flat die thread rolling machines are more than just tools; they are precision-engineered solutions that elevate the quality and efficiency of thread production. Their adaptability, durability, and the superior threads they produce make them a staple in modern manufacturing facilities. As technology continues to advance, one can expect these machines to become even more sophisticated, further enhancing their capabilities and expanding their application scope. Whether in automotive bolts, aerospace components, or industrial machinery, flat die thread rolling machines remain an essential element in creating robust, reliable threads that withstand the test of time. Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025