-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Flat Die Thread Rolling Machine Producers and Their Innovative Technologies

The Advancements in Flat Die Thread Rolling Machine Manufacturing

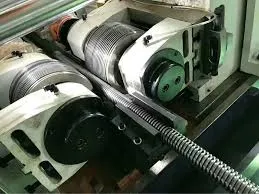

In recent years, the manufacturing industry has witnessed significant advancements in various technologies, including the production of flat die thread rolling machines. These machines are pivotal in the metalworking sector, primarily used for creating threads on rods and bars without removing material, thus preserving the metal's integrity and enhancing its strength. This article delves into the key aspects of flat die thread rolling machine manufacturers and the innovations shaping the industry.

Understanding Flat Die Thread Rolling

Flat die thread rolling is a highly efficient process that utilizes two flat dies to deform materials into the desired thread profiles. Unlike traditional methods such as cutting, this technique offers several advantages, including increased durability of the threads, improved surface finish, and reduced waste. The ability to produce precise threads makes these machines invaluable in various applications, ranging from automotive parts to fasteners in construction.

The Role of Manufacturers

Manufacturers of flat die thread rolling machines play a crucial role in advancing this technology. They focus on designing machines that not only improve productivity but also ensure energy efficiency. Leading manufacturers invest heavily in research and development to innovate their products, enhancing features like automation, precision, and ease of operation.

1. Automation and Smart Technology

The integration of automation in thread rolling machines has transformed how manufacturers operate. Automated systems minimize human intervention, which reduces the risk of errors and increases efficiency. Smart technology, such as IoT-enabled devices, provides real-time monitoring and analytics, allowing manufacturers to assess machine performance and make data-driven decisions. These advancements not only streamline production processes but also reduce downtime and operational costs.

flat die thread rolling machine manufacturers

2. Customization and Flexibility

Another significant trend among manufacturers is the shift towards customization. As industries evolve, the demand for tailored solutions grows. Leading manufacturers now offer flexible machines that can accommodate various thread sizes and profiles, allowing for swift changes in production lines. This adaptability is critical for businesses looking to stay competitive in fast-paced markets.

3. Sustainable Practices

Sustainability is becoming increasingly vital in manufacturing. To meet global environmental standards, manufacturers of flat die thread rolling machines are implementing eco-friendly practices. This includes using materials that reduce energy consumption and implementing recycling processes for metal waste. Sustainable manufacturing not only appeals to environmentally conscious consumers but also helps businesses minimize costs and enhance their brand reputation.

Challenges and Solutions

Despite these advancements, manufacturers face several challenges. The rapid pace of technological change requires continual investment in equipment and training. Additionally, sourcing skilled labor remains a significant hurdle. To address this, manufacturers are focusing on training programs that equip their workforce with the necessary skills to operate modern machines effectively. Collaborations with educational institutions are also growing, aiming to build a pipeline of skilled workers prepared to meet industry demands.

Conclusion

Flat die thread rolling machine manufacturers are at the forefront of innovation in the manufacturing sector. Their commitment to automation, customization, and sustainability is transforming how threads are produced, enhancing efficiency and quality. As the industry continues to evolve, these manufacturers will play a critical role in shaping the future of metalworking, ensuring that they not only meet current demands but also anticipate future trends. Through continuous improvement and adaptation, the flat die thread rolling machine manufacturing sector is poised for significant growth in the coming years, reflecting the dynamic nature of the global market.