-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

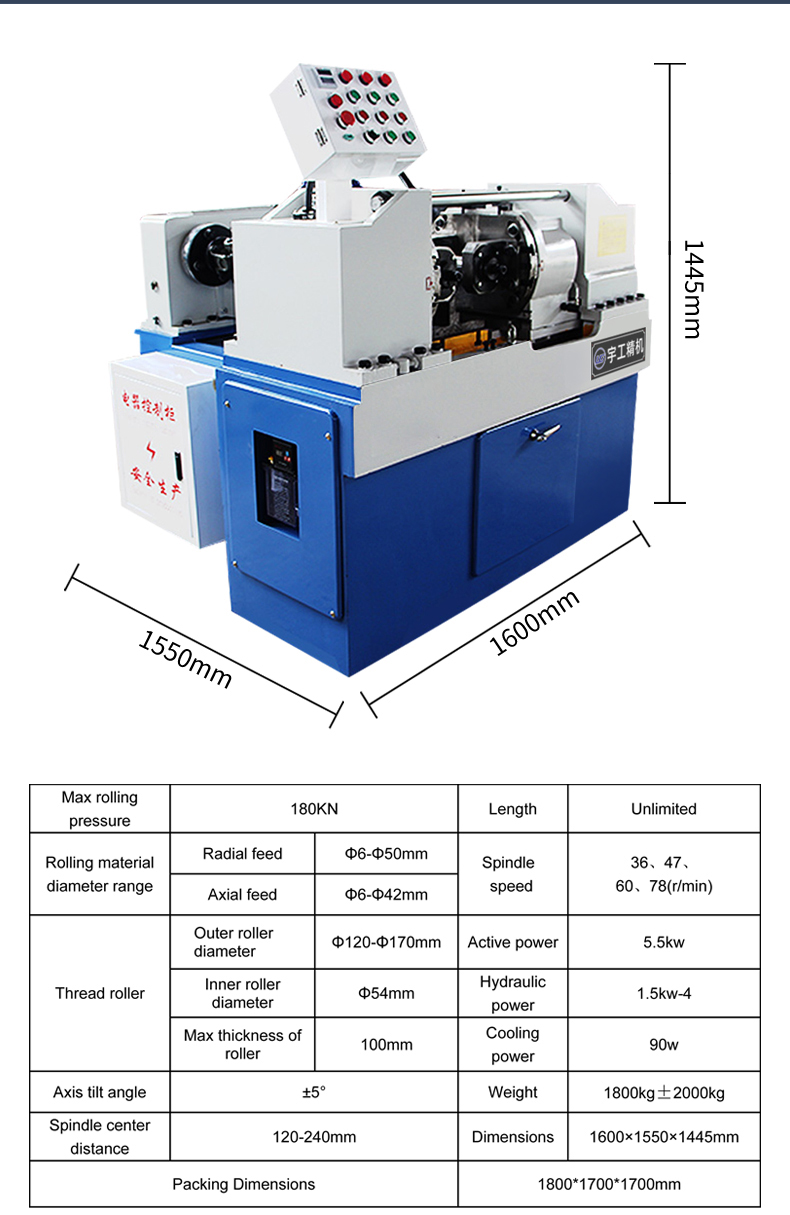

Flat Thread Rolling Machine Solutions for Efficient Manufacturing and Precision Engineering

Flat Thread Rolling Machine Products A Comprehensive Overview

In the world of manufacturing, the flat thread rolling machine plays a pivotal role in producing high-quality threaded components efficiently. This innovative piece of machinery is specifically designed to produce flat threads, which are crucial in various applications ranging from automotive and aerospace industries to construction and furniture making. As manufacturers strive for precision and productivity, the popularity of flat thread rolling machines is on the rise, thanks to their unique advantages and capabilities.

Understanding Flat Thread Rolling

Flat thread rolling is a cold forming process that utilizes two rotating dies to shape a workpiece into a specified thread profile without cutting away material. This process is inherently advantageous because it not only enhances material strength through work hardening but also allows for close tolerances and improved surface finishes. Traditional machining methods might remove excess material, leading to wasted resources and time; thread rolling, on the other hand, retains most of the initial material, making it a more efficient solution.

Key Features of Flat Thread Rolling Machines

1. Precision and Accuracy One of the standout features of flat thread rolling machines is their ability to produce highly accurate threads. The synchronized movement of the dies ensures uniformity, minimizing inconsistencies in thread pitch and diameter, which is essential in applications requiring tight tolerances.

2. Versatility Flat thread rolling machines are versatile and can work with various materials, including steel, aluminum, and other alloys. This flexibility makes them suitable for manufacturers in multiple industries, each with its unique threading needs.

3. Enhanced Production Rates The nature of the rolling process allows for higher production rates compared to traditional machining methods. This efficiency is particularly beneficial in high-demand environments where quick turnaround times are crucial.

4. Cost-efficiency While the initial investment in flat thread rolling machines may be significant, the long-term cost savings are substantial. The reduction of scrap material and the expedited production processes lower operational costs, making rolling machines an economically viable option for many manufacturers.

5. Environmentally Friendly The cold forming process significantly decreases energy consumption compared to hot processes, thus reducing the carbon footprint of manufacturing operations. This characteristic aligns well with the growing trend towards sustainable manufacturing practices.

Applications of Flat Thread Rolling Machines

Flat thread rolling machines find application across various sectors due to their efficiency and reliability. Some notable applications include

flat thread rolling machine products

- Automotive Industry In the automotive sector, flat threads are widely used for bolts, screws, and fasteners that require high strength and durability

. The performance of these components is crucial for vehicle safety and functionality.- Construction The construction industry relies on robust threaded products for structural applications. Flat thread rolling machines aid in the mass production of anchor bolts, rebar ties, and numerous other fastening solutions.

- Aerospace In aerospace, where safety and precision are paramount, flat thread rolling is indispensable. Roll-formed threads are often utilized in critical components that face high-stress conditions during flight, ensuring reliability and performance.

- Furniture Manufacturing The furniture industry benefits from the use of flat thread rolling machines to produce screws and connectors that hold various pieces together, ensuring durability and ease of assembly.

Choosing the Right Machine for Your Needs

When selecting a flat thread rolling machine, several factors should be considered

- Production Volume Determine the expected daily output. This will help in sizing the machine appropriately to meet production demands without sacrificing quality.

- Material Type Ensure the machine can handle the specific materials you intend to work with, as different materials might require different tooling and processes.

- Die Design Custom die design may be necessary for unique thread profiles. Collaborating with experienced suppliers can ensure that the dies are optimized for performance.

- Automation Features Advanced machines offer automation capabilities that can further enhance productivity and reduce labor costs.

In conclusion, flat thread rolling machines are an integral aspect of modern manufacturing, providing efficiency, precision, and flexibility across various industries. As manufacturers continue to embrace technological advancements, the importance and application of this machinery are likely to expand, driving innovations and optimizing production processes in the years to come.