-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

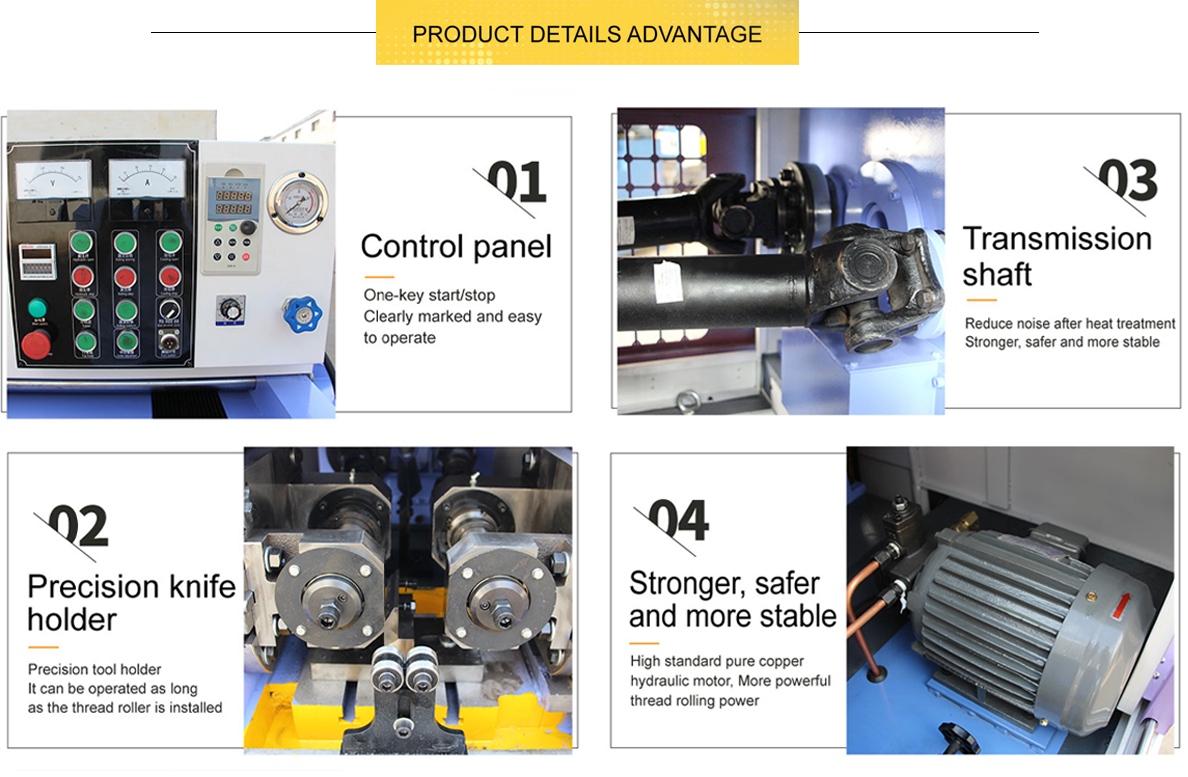

Suppliers of Flat Thread Rolling Machines for Efficient Manufacturing Solutions

The Importance of Flat Thread Rolling Machines and Their Suppliers

In the fast-evolving landscape of manufacturing, flat thread rolling machines play a pivotal role in the production of high-quality threaded components. These machines offer a reliable and efficient method for forming threads on metals, which is crucial in various industries including automotive, aerospace, and construction. However, to fully leverage the capabilities of these machines, selecting the right supplier is equally important.

What is Flat Thread Rolling?

Flat thread rolling is a cold forming process where flat metal strips or parts are transformed into threaded components without the need for cutting. This process uses two rotating dies that apply pressure to the workpiece, resulting in precise threads that are both strong and durable. One of the significant advantages of flat thread rolling is the reduction of material waste compared to traditional machining processes. Additionally, the cold forming method enhances the tensile strength of the final product, making it suitable for high-stress applications.

Benefits of Using Flat Thread Rolling Machines

1. Efficiency Flat thread rolling machines are designed for high-speed production, enabling manufacturers to produce large quantities of threaded components in a shorter duration. This efficiency is crucial in meeting the demands of industries that require rapid and continuous production cycles.

2. Quality The precision offered by flat thread rolling machines leads to consistent thread profiles and dimensions. This quality is essential for ensuring that threaded parts fit together seamlessly, which is a critical factor in assembly processes across various applications.

3. Cost-Effectiveness By minimizing material waste and reducing the need for secondary operations, manufacturers can significantly lower production costs. The ability to produce high volumes of quality components translates to better profit margins.

4. Versatility Flat thread rolling machines can accommodate various materials such as steel, aluminum, and even some plastics, making them suitable for a wide range of applications. The adaptability of these machines allows manufacturers to diversify their product offerings.

flat thread rolling machine supplier

Selecting the Right Supplier

When it comes to sourcing flat thread rolling machines, choosing the right supplier can make all the difference. Here are several factors to consider when evaluating potential suppliers

1. Reputation and Experience A supplier with a solid reputation in the industry and years of experience is more likely to provide reliable machines and services. Researching customer testimonials and case studies can offer valuable insights into their track record.

2. Quality Assurance It's essential to ensure that the supplier adheres to strict quality control measures during the manufacturing process. Certification standards such as ISO can be indicators of their commitment to producing high-quality machines.

3. After-Sales Support The availability of after-sales support, including maintenance services and spare parts, is crucial for keeping machines running smoothly. A supplier that offers comprehensive support can help minimize downtime and extend the life of the equipment.

4. Customization Options Different manufacturers have varying requirements regarding the specifications and features of thread rolling machines. A supplier that can offer customization options will be more suitable for meeting specific operational needs.

5. Technology and Innovation Suppliers that invest in the latest technology and are open to integrating advanced features into their machines can provide customers with enhanced performance and efficiency.

Conclusion

The significance of flat thread rolling machines in modern manufacturing cannot be overstated. They not only improve production efficiency and quality but also contribute to cost reductions in manufacturing processes. However, the success of using these machines largely depends on selecting the right supplier. By considering factors such as reputation, quality assurance, after-sales support, customization options, and technological innovations, manufacturers can make informed decisions that lead to long-term benefits and superior performance in their operations. As industries continue to evolve, the right partnership with a reliable supplier is crucial to staying competitive.