-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Quality Thread Rolling Machines Available for Purchase in China for Various Industrial Uses

China’s Thread Rolling Machines for Sale A Comprehensive Overview

In recent years, the manufacturing landscape in China has seen significant developments, especially in the field of industrial machinery. Among the various machines that contribute to the manufacturing processes, thread rolling machines have garnered particular attention. These machines are essential for producing high-quality threaded components used in various applications, including automotive, aerospace, and construction industries. In this article, we will explore the features and advantages of thread rolling machines produced in China, as well as the factors to consider when purchasing one.

Understanding Thread Rolling Machines

Thread rolling machines are specialized equipment designed to create threads on metal workpieces through a process known as rolling. The operation involves plastic deformation of the material, allowing for the formation of threads without removing any material, which is a significant advantage compared to traditional cutting methods. This process leads to a smoother surface finish, improved strength, and higher dimensional accuracy of the threads.

Why Choose Chinese Thread Rolling Machines?

1. Cost-Effectiveness One of the foremost reasons companies opt for Chinese thread rolling machines is their affordability. Manufacturers in China tend to offer competitive pricing without compromising on quality. This aspect is particularly appealing for small to medium-sized enterprises looking to minimize production costs.

2. Diverse Range of Products Chinese manufacturers produce a wide variety of thread rolling machines that cater to different needs and specifications. Whether you're looking for a machine suitable for small-scale production or one that can handle large volumes, the Chinese market has a solution. Options range from manual to fully automatic machines, with varying levels of complexity and technological advancement.

3. Technological Advancements Despite previous perceptions, many Chinese manufacturers are investing heavily in research and development. This commitment ensures that their machines are equipped with modern technology, such as CNC (Computer Numerical Control) systems, which enhance precision and ease of use. This evolution in technology has helped Chinese thread rolling machines to compete with those made in more traditional manufacturing countries.

4. Quality Assurance While quality may have been a concern in the past, reputable Chinese manufacturers now emphasize quality control measures. Many adhere to international standards, such as ISO, and implement rigorous testing procedures to ensure their machines perform reliably and meet customer expectations.

china thread rolling machines for sale

Factors to Consider When Purchasing

Before making a purchase, it is crucial for buyers to consider several factors

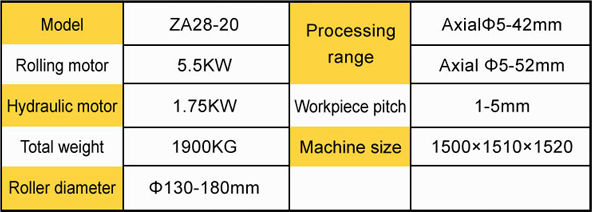

1. Specifications Different projects require different thread specifications. Buyers should ensure that the machine they choose can handle the specific thread sizes and types needed for their production.

2. Supplier Reputation Researching the reputation of the manufacturer is critical. Look for suppliers with positive reviews and a solid track record in exporting machinery. Engaging with previous customers can provide valuable insights into the machine’s performance and the manufacturer’s after-sales support.

3. After-Sales Service A reliable after-sales service is essential when investing in machinery. Ensure that the supplier offers adequate support, such as training, maintenance, and easy access to spare parts.

4. Compliance with Standards Verify that the machines comply with relevant safety and operational standards in your region to avoid legal issues down the line.

Conclusion

Chinese thread rolling machines present a compelling option for businesses involved in manufacturing threaded components. Their blend of affordability, diverse offerings, and increasing emphasis on quality and technology makes them an attractive choice for manufacturers worldwide. By considering the key factors outlined above, potential buyers can make informed decisions and ultimately enhance their production capabilities with these efficient machines. As global industries continue to evolve, the role of reliable machinery such as thread rolling machines will remain integral to maintaining competitive manufacturing practices.