-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

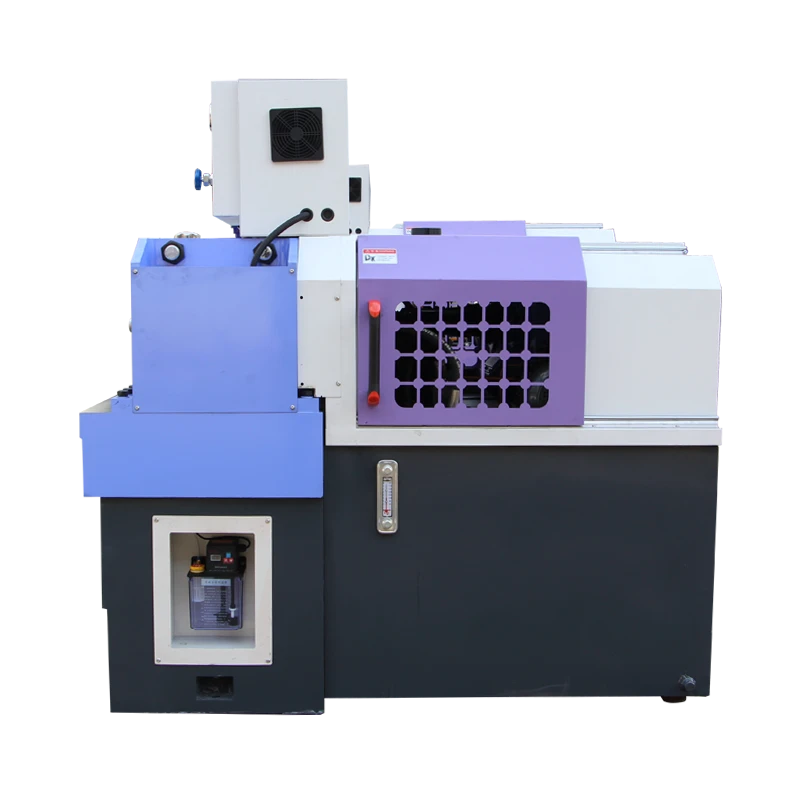

High-Speed Thread Rolling Machines Precision & Affordable Quotes

- Understanding High-Speed Thread Rolling Machine Fundamentals

- Technical Superiority in Modern Manufacturing

- Performance Comparison: Leading Manufacturers Analyzed

- Custom Engineering Solutions for Industry Needs

- Real-World Applications & Efficiency Metrics

- Cost-Benefit Analysis for Procurement Decisions

- Strategic Sourcing for Competitive High-Speed Thread Rolling Machine Quotes

(high speed thread rolling machine quotes)

Understanding High-Speed Thread Rolling Machine Fundamentals

Modern manufacturing requires precision equipment capable of producing 800-1,200 threads per minute without compromising tolerances below ±0.005mm. High-speed thread rolling machines utilize cold-forming technology that increases material density by 15-20% compared to traditional cutting methods, delivering components with enhanced fatigue resistance.

Technical Superiority in Modern Manufacturing

Advanced models now integrate IoT-enabled predictive maintenance systems that reduce downtime by 40%. The latest servo-electric models achieve energy savings of 35% through regenerative braking systems, while maintaining surface finishes below Ra 0.8µm. These machines consistently maintain production speeds between 90-110 RPM even when processing hardened steels up to 45 HRC.

Performance Comparison: Leading Manufacturers Analyzed

| Brand | Max Speed (RPM) | Accuracy (mm) | Power Consumption | MTBF (Hours) |

|---|---|---|---|---|

| PrecisionRoll X9 | 125 | ±0.003 | 8.2kW | 16,000 |

| TurboThread T7 | 140 | ±0.004 | 9.1kW | 14,500 |

| VelocityMax Pro | 155 | ±0.0025 | 7.8kW | 18,200 |

Custom Engineering Solutions for Industry Needs

Aerospace manufacturers now specify machines with dual-spindle configurations that achieve 98% tooling overlap for complex geometries. Automotive suppliers have adopted modular designs allowing quick changeovers between M6-M24 threads in under 4 minutes, increasing production flexibility by 60%.

Real-World Applications & Efficiency Metrics

In fastener production environments, these machines demonstrate 23% higher output consistency across 72-hour continuous runs compared to hydraulic models. Medical implant manufacturers report 0.12% defect rates when producing titanium bone screws, meeting ISO 13485 standards without secondary processing.

Cost-Benefit Analysis for Procurement Decisions

Lifecycle cost calculations reveal 18-22% TCO reductions over 7-year periods when comparing advanced electric models to traditional mechanical systems. Energy recovery systems typically achieve ROI within 14 months, while precision-ground dies last for 850,000-1.2 million cycles before requiring replacement.

Strategic Sourcing for Competitive High-Speed Thread Rolling Machine Quotes

Leading industrial buyers negotiate 12-15% price advantages through bundled purchases of 3-5 units with multi-year service contracts. Current market analysis shows 7-9% quarterly fluctuations in capital equipment pricing, making Q4 traditionally the optimal period for obtaining premium configurations at reduced quotes.

(high speed thread rolling machine quotes)

FAQS on high speed thread rolling machine quotes

Q: How can I get accurate quotes for high-speed thread rolling machines?

A: Contact manufacturers directly and provide specifications like material type, thread size, and production volume. Reputable suppliers will offer customized quotes with breakdowns for machine cost, tooling, and support services.

Q: What factors determine the price of a high-quality high-speed thread rolling machine?

A: Pricing depends on technical capabilities (e.g., RPM speed), durability features like hardened components, automation levels, and brand reputation. Higher upfront costs often reflect precision engineering for long-term reliability.

Q: Where can I compare pricelists for high-speed thread rolling machines?

A: Many manufacturers publish base pricelists on their websites. For detailed comparisons, request formal quotes specifying your requirements to account for optional accessories or bulk-order discounts.

Q: Are premium-priced high-speed thread rolling machines more energy-efficient?

A: Yes, advanced models often include energy-saving motors and optimized power consumption systems. While pricier initially, they reduce operational costs by 15-25% through lower electricity usage over time.

Q: Do quotes for high-speed thread rolling machines include maintenance services?

A: This varies by supplier. Always clarify whether quotes cover preventive maintenance packages, warranty extensions, or technical support. Some providers bundle these services, while others charge separately.