-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

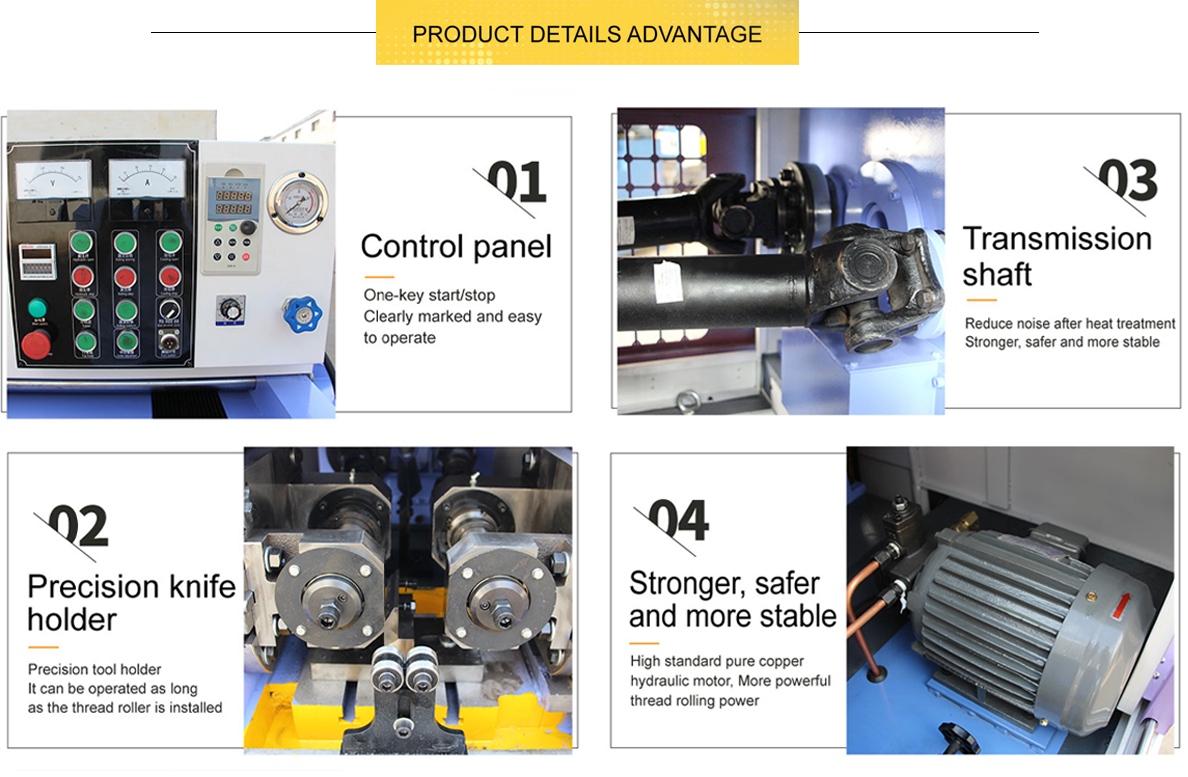

high quality hydraulic thread rolling machine

High-Quality Hydraulic Thread Rolling Machines Advancements and Applications

In the world of manufacturing and engineering, precision and efficiency are paramount. One key technology that has gained prominence in achieving these goals is the hydraulic thread rolling machine. This equipment is designed to produce high-quality threaded components with outstanding precision and surface finish. With advancements in technology, these machines have evolved significantly, offering a range of benefits that are transforming how industries approach threading operations.

What is a Hydraulic Thread Rolling Machine?

A hydraulic thread rolling machine utilizes hydraulic pressure to deform materials and create threads. Unlike traditional cutting methods, which remove material, thread rolling forms threads by displacing the material around the tool. This process not only enhances the strength of the threads but also improves the surface finish, making it ideal for critical applications in various industries.

Advantages of Hydraulic Thread Rolling Machines

1. Improved Strength and Durability The rolling process compresses the material's grain structure, resulting in threads that are stronger and more resistant to wear. This is particularly beneficial for components used in high-stress environments, such as aerospace and automotive applications.

2. Enhanced Surface Finish The cold-working nature of thread rolling produces finer surface finishes compared to cutting methods. This results in less need for additional processing, saving time and resources during production.

3. Higher Production Rates Hydraulic thread rolling machines are designed for high-speed operations. Their ability to handle multiple threads in a single pass significantly increases production efficiency, allowing manufacturers to meet growing demands faster.

4. Versatility Modern hydraulic machines can accommodate different materials, including metals like steel, aluminum, and brass. They can also be adjusted to produce various thread sizes and types, making them suitable for a wide range of applications.

high quality hydraulic thread rolling machine

Applications in Various Industries

Hydraulic thread rolling machines find applications across a multitude of sectors

- Aerospace With the stringent requirements for safety and reliability, the aerospace industry benefits from the strength and precision of rolled threads in components such as bolts and fasteners.

- Automotive The automotive sector relies heavily on threaded components for assemblies, making thread rolling an ideal solution for producing high-quality parts that can withstand rigorous conditions.

- Construction In construction, products like rebar and structural components require robust threading to ensure they can support significant loads. Hydraulic thread rolling machines meet these demands with ease.

- Manufacturing General manufacturing uses these machines for creating various threaded parts, supplementing a wide range of products from machinery to electronics.

Future Innovations

As technology continues to evolve, hydraulic thread rolling machines are set to become even more advanced. Innovations such as automation, smart manufacturing integration, and enhanced control systems will enhance operational efficiency and precision. Furthermore, the implementation of Industry 4.0 concepts, including predictive maintenance and real-time monitoring, can significantly reduce downtime and improve overall productivity.

Conclusion

High-quality hydraulic thread rolling machines represent a significant advancement in manufacturing technology. Their ability to produce durable, precise, and cost-effective threaded components makes them an invaluable asset across multiple industries. As manufacturers strive to improve efficiency and reduce production costs, investing in modern hydraulic thread rolling solutions will play a crucial role in maintaining competitiveness in the ever-evolving global market. With the promise of continual innovation, the future of thread rolling looks exceptionally bright, poised to meet the demands of tomorrow's manufacturing challenges.