-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

high quality reed thread rolling machines

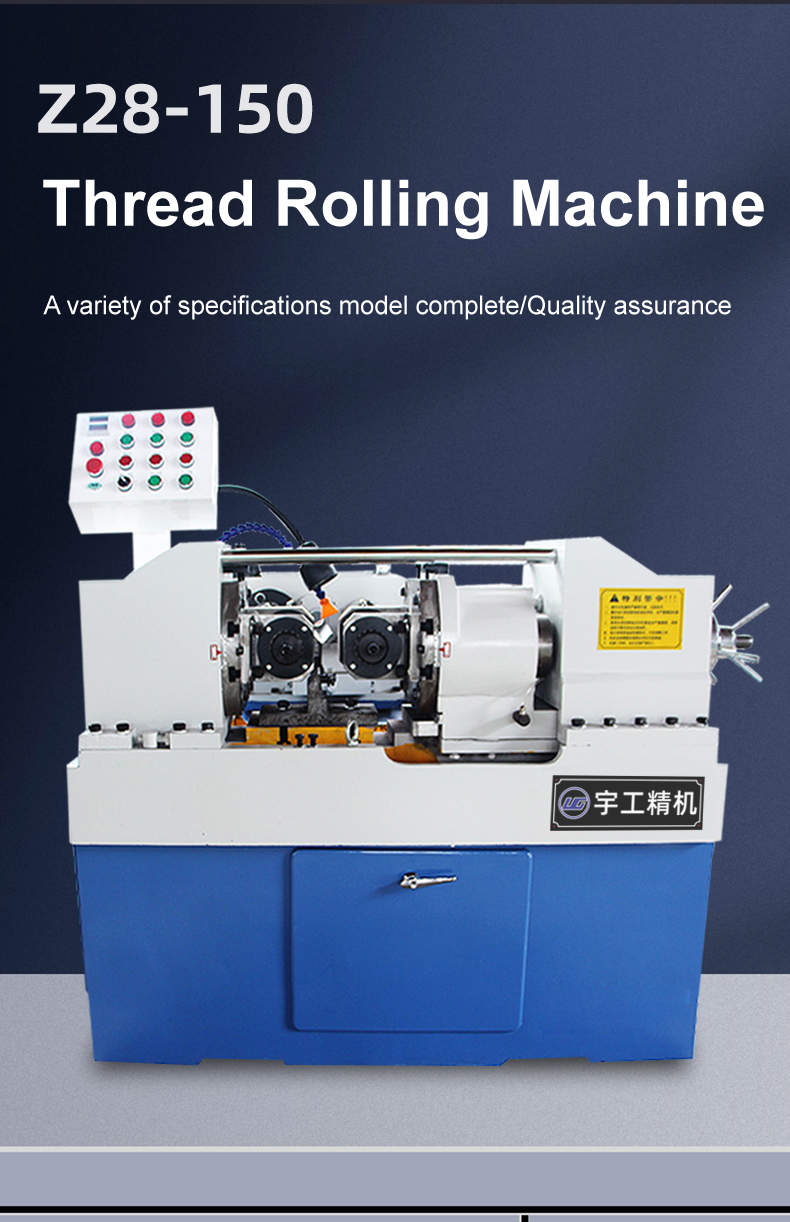

High-Quality Reed Thread Rolling Machines Revolutionizing Precision Manufacturing

In the world of precision manufacturing, the significance of thread rolling cannot be overstated. Among the various tools and techniques employed in this process, high-quality reed thread rolling machines stand out as a pivotal component, enhancing both quality and efficiency in production. These machines play a crucial role in creating strong, precise threads on metal components, which are essential in countless applications across diverse industries.

Understanding Thread Rolling

Thread rolling is a cold-forming process wherein thread shapes are formed on a cylindrical workpiece by deforming the material with a pair of hardened dies. This method is advantageous as it enhances the mechanical properties of the material compared to traditional cutting methods. The high pressures exerted during rolling result in a denser, stronger surface, reducing the likelihood of defects and enhancing overall durability.

What are Reed Thread Rolling Machines?

Reed thread rolling machines are specialized equipment designed to automate the thread rolling process. Known for their reliability and precision, these machines are engineered to handle various sizes of workpieces and can produce multiple thread profiles. These machines incorporate advanced technology, including programmable controls, which enable manufacturers to adjust parameters easily, thus ensuring versatility in production setups.

Key Features of High-Quality Reed Thread Rolling Machines

1. Precision Engineering At the core of any high-quality thread rolling machine is precision. Reed machines are built with exacting tolerances, ensuring that the threads produced are uniform and meet the specified standards.

2. Durability and Longevity High-quality materials and components are used in the construction of these machines, which leads to enhanced durability. The use of robust rollers and dies helps the machines withstand the rigors of continuous operation without significant wear and tear.

high quality reed thread rolling machines

3. Efficiency Reed thread rolling machines are designed for high productivity. Their automation capabilities allow for rapid changeovers and minimal downtime, which are critical in a fast-paced manufacturing environment.

4. User-Friendly Interfaces Modern reed machines come equipped with intuitive interfaces, making it easier for operators to monitor and adjust settings. This user-friendly design reduces the learning curve and enhances overall operational efficiency.

5. Energy Efficiency Many high-quality rolling machines are engineered with energy efficiency in mind, minimizing power consumption while maximizing output. This not only helps reduce operational costs but also supports sustainable manufacturing practices.

Applications of Reed Thread Rolling Machines

Reed thread rolling machines find applications across a variety of sectors, including

- Automotive Industry Used for producing bolts, nuts, and other critical fasteners that must withstand high stress and varying environmental conditions. - Aerospace Threaded components used in aircraft must meet stringent safety and performance standards, making rolling machines an essential tool in their manufacturing. - Construction Fasteners for construction applications require high-strength threads to support structural loads, making thread rolling the preferred method. - Electronics Many electronic devices require precisely threaded components for connecting parts, ensuring reliable performance.

Conclusion

The integration of high-quality reed thread rolling machines into manufacturing processes not only strengthens the performance of threaded components but also optimizes overall production efficiency. As industries continue to evolve and require stronger, lighter, and more efficient components, the demand for advanced rolling technologies will only increase. Investing in high-quality thread rolling machines is, therefore, vital for manufacturers aiming to maintain competitive advantage and meet increasingly stringent quality demands.

In a fast-evolving industrial landscape, embracing precision and innovation through the adoption of high-quality reed thread rolling machines is a strategic move that promises to enhance productivity and reliability in manufacturing operations. The future of thread manufacturing is bright, driven by the advancements in machine technology and the growing recognition of the importance of quality in the production process.