-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

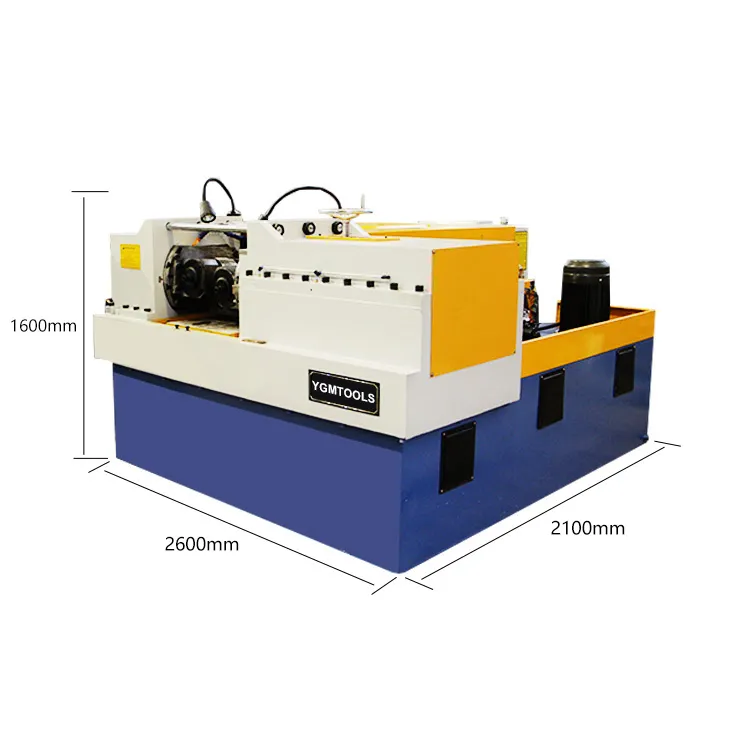

Advanced Precision Thread Rolling Machines for Optimal Performance and Quality Production

The Importance of High-Quality Thread Rolling Machines in Manufacturing

In the realm of precision manufacturing, thread rolling machines play a crucial role in producing high-quality threaded fasteners and components. These machines are instrumental in various industries, including automotive, aerospace, and construction, where the reliability and strength of threaded parts are paramount. The efficiency and quality of the end products are largely influenced by the design and capabilities of the thread rolling machines utilized in production.

What is Thread Rolling?

Thread rolling is a cold-forming process that uses specially designed dies to create threads on the surface of a metal workpiece. Unlike traditional cutting methods that remove material, thread rolling displaces it, resulting in a more robust and fatigue-resistant thread. This method is particularly advantageous for producing high-volume batches of threaded components, as it significantly speeds up production while maintaining consistent quality.

High-Quality Thread Rolling Machines Key Features

Investing in high-quality thread rolling machines can lead to numerous benefits for manufacturers. Here are some essential features that define these machines

1. Precision Engineering Premium thread rolling machines are engineered with high accuracy, ensuring that threads are produced to stringent tolerances. This level of precision reduces the likelihood of defects and improves the overall integrity of the threaded products.

2. Robust Construction High-quality machines are constructed from durable materials that withstand the rigors of continuous operation. This robustness not only extends the lifespan of the equipment but also enhances reliability, minimizing downtime due to maintenance issues.

3. Versatile Capability Advanced thread rolling machines often come with versatile capabilities, allowing them to roll various types of threads, including external and internal threads. They are equipped to handle different materials, including metals and alloys, making them suitable for a wide range of applications.

4. Automation Features Automated thread rolling machines can significantly enhance productivity. Features like programmable controls and automatic feeding systems enable manufacturers to streamline their operations, reduce labor costs, and minimize human error.

high quality thread rolling machine

5. Energy Efficiency High-quality machines are designed to be energy-efficient, helping manufacturers reduce their operational costs. Energy-efficient models not only lower utility bills but also contribute to sustainability efforts by minimizing the carbon footprint associated with thread manufacturing.

Benefits of High-Quality Thread Rolling Machines

The advantages of utilizing high-quality thread rolling machines extend beyond initial production efficiencies. Here are some benefits that manufacturers can enjoy

- Increased Strength of Fasteners The cold-forming process used in thread rolling inherently strengthens the metal fibers, resulting in threads that can withstand higher loads and resist stripping during use.

- Cost-Effectiveness Although high-quality machines may require a higher initial investment, their durability, reduced maintenance needs, and increased production efficiency often lead to lower long-term operating costs.

- Higher Production Rates By utilizing efficient machinery that can produce high volumes of threaded parts quickly and accurately, manufacturers can increase their output and meet market demands more effectively.

- Enhanced Product Quality Consistent quality in threaded fasteners translates to better performance in their applications, minimizing the likelihood of failure and increasing customer satisfaction.

Conclusion

In conclusion, high-quality thread rolling machines are vital assets in the manufacturing industry. Their superior precision, robustness, versatility, and efficiency ensure that manufacturers can produce reliable and high-quality threaded components. As industries continue to emphasize quality and performance, investing in advanced thread rolling technology will undoubtedly pay dividends in the long run, solidifying a manufacturer’s reputation and success in an increasingly competitive market.