-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 15, 2025 01:45

Back to list

high quality thread rolling machine for sale

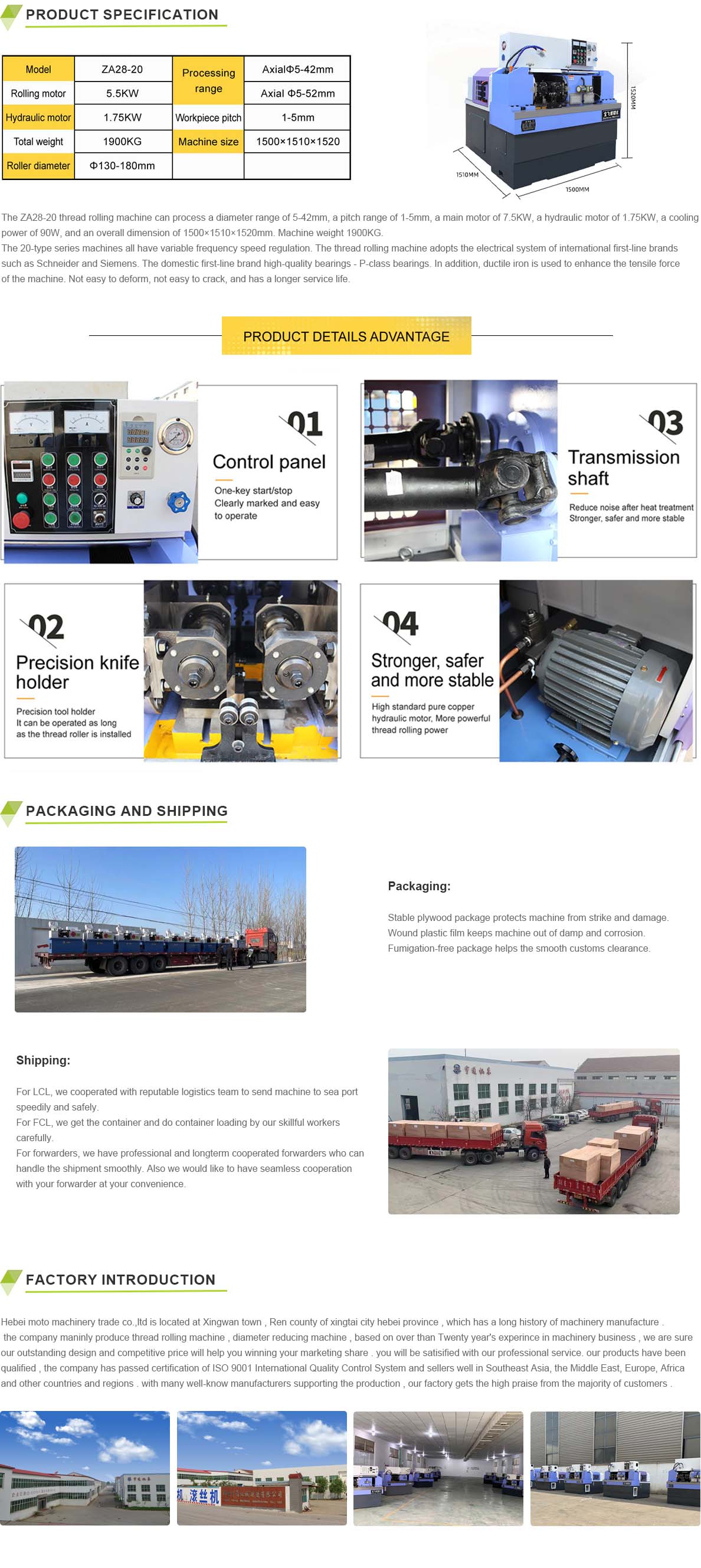

In the rapidly advancing field of manufacturing, the demand for precision and efficiency in machinery is constantly evolving. Among the indispensable equipment in this arena is the high-quality thread rolling machine, a pivotal component for industries requiring robust and durable threaded parts. Investing in a thread rolling machine can significantly enhance production efficiency and product durability, making it a valuable asset for manufacturers aiming to stay competitive. This article explores the exceptional features, benefits, and considerations when purchasing a high-quality thread rolling machine for sale.

Choosing the Right Machine When looking for a high-quality thread rolling machine for sale, several factors should be considered to ensure a sound investment. Assessing the type of threads required, the volume of production, and available space in the facility are critical initial steps. Furthermore, potential buyers should scrutinize the machine’s specifications, such as thread diameter capacity, speed, and control systems, to ensure that it aligns with their production needs. Consulting with industry experts and conducting thorough research on manufacturers and models can provide deeper insights, guiding buyers toward a more informed decision. Economic Impact The economic benefits of investing in a superior thread rolling machine are multifaceted. By improving production efficiency, reducing material waste, and producing high-strength threaded parts, manufacturers can achieve a competitive edge in the market. Additionally, the ability to produce custom threads can open new opportunities and business avenues, further enhancing revenue potential. Environmental Considerations High-quality thread rolling machines also offer environmental advantages. The rolling process itself is environmentally friendly, as it eliminates the need for cutting oils and reduces waste. Opting for energy-efficient models can further enhance sustainability by lowering energy consumption, aligning with environmental standards and reducing operational costs. In conclusion, the purchase of a high-quality thread rolling machine is a strategic investment for any manufacturer aiming to enhance their production capabilities. With advances in technology and a focus on precision, durability, and reliability, these machines offer unparalleled benefits that can significantly impact an organization’s bottom line. By carefully selecting the right machine to suit specific needs and leveraging its advanced features, manufacturers can ensure long-term success and sustainability in their operations.

Choosing the Right Machine When looking for a high-quality thread rolling machine for sale, several factors should be considered to ensure a sound investment. Assessing the type of threads required, the volume of production, and available space in the facility are critical initial steps. Furthermore, potential buyers should scrutinize the machine’s specifications, such as thread diameter capacity, speed, and control systems, to ensure that it aligns with their production needs. Consulting with industry experts and conducting thorough research on manufacturers and models can provide deeper insights, guiding buyers toward a more informed decision. Economic Impact The economic benefits of investing in a superior thread rolling machine are multifaceted. By improving production efficiency, reducing material waste, and producing high-strength threaded parts, manufacturers can achieve a competitive edge in the market. Additionally, the ability to produce custom threads can open new opportunities and business avenues, further enhancing revenue potential. Environmental Considerations High-quality thread rolling machines also offer environmental advantages. The rolling process itself is environmentally friendly, as it eliminates the need for cutting oils and reduces waste. Opting for energy-efficient models can further enhance sustainability by lowering energy consumption, aligning with environmental standards and reducing operational costs. In conclusion, the purchase of a high-quality thread rolling machine is a strategic investment for any manufacturer aiming to enhance their production capabilities. With advances in technology and a focus on precision, durability, and reliability, these machines offer unparalleled benefits that can significantly impact an organization’s bottom line. By carefully selecting the right machine to suit specific needs and leveraging its advanced features, manufacturers can ensure long-term success and sustainability in their operations.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025