-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Affordable High-Quality Thread Rolling Machines for All Your Industrial Needs

Understanding the Price of High-Quality Thread Rolling Machines

In the world of manufacturing, precision and efficiency are paramount. Among the various processes employed to create fasteners and similar components, thread rolling stands out as one of the most effective methods. As industries ranging from automotive to aerospace increasingly rely on high-quality threaded components, the demand for thread rolling machines has surged. This has led to a parallel interest in understanding the pricing of these critical pieces of equipment.

What Are Thread Rolling Machines?

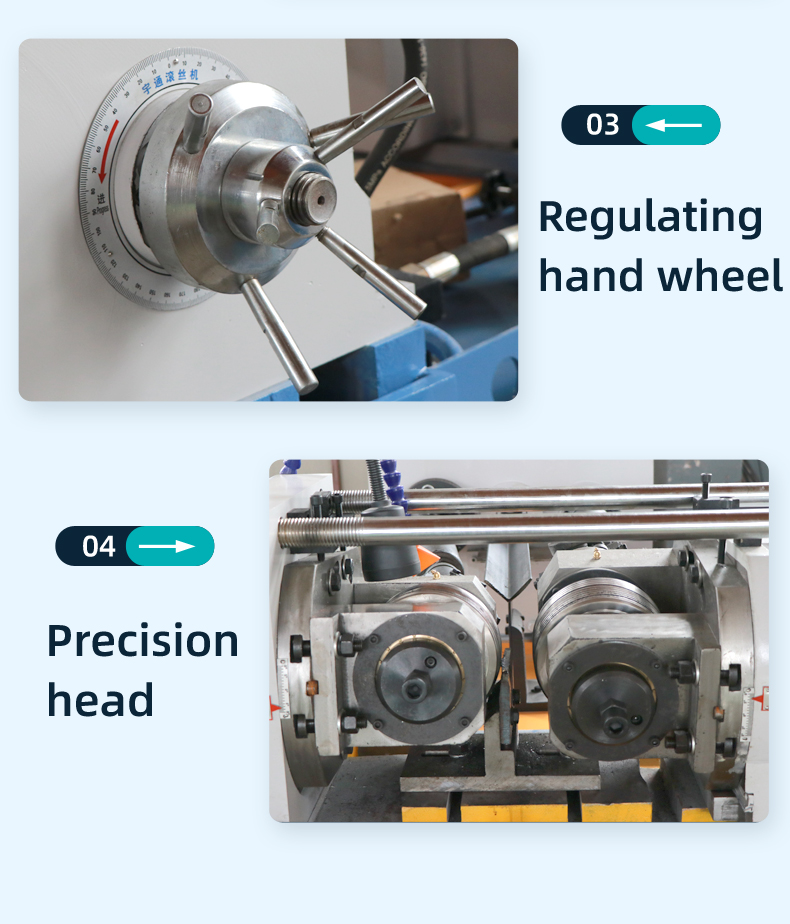

Thread rolling machines are specialized pieces of machinery used to form threads on metal rods and other materials. Unlike traditional machining methods, which cut material away to create threads, thread rolling is a cold-forming process that displaces material. This offers several advantages, including improved strength, better surface finish, and a reduction in material waste. Given their efficiency and the quality of the threads produced, high-quality thread rolling machines are an essential asset for manufacturers aiming for excellence in their products.

Factors Influencing the Price

1. Quality and Brand Reputation One of the most significant factors influencing the price of thread rolling machines is the quality associated with different manufacturers. Established brands that are known for their high-quality equipment typically command higher prices due to their reliability and performance. Investing in a reputable brand often translates to better support, warranties, and machine longevity.

2. Machine Specifications The specific features of a thread rolling machine also significantly affect its price. Machines with advanced technology, such as programmable systems, high-speed operation capabilities, and multi-axis functionality, tend to be more expensive. While these features may come at a premium, they can increase productivity and reduce operational costs in the long run.

3. Size and Capacity Thread rolling machines vary in size and capacity. Smaller machines designed for low-volume production can be more affordable but may not provide the efficiency required for larger operations. Industrial-grade machines suitable for high-volume production typically come at a higher price due to their robust construction and greater operational capabilities.

high quality thread rolling machine price

4. Customization Some manufacturers offer customization options that allow buyers to tailor machines to their specific production needs. Custom solutions often drive up the initial investment, but they can result in better overall efficiency and output quality. Companies should weigh the cost of customization against potential long-term benefits before making a decision.

5. Market Trends Economic factors and trends in the manufacturing industry can also influence prices. For instance, an increase in demand for fasteners in the construction or automotive sectors can lead to higher prices for thread rolling machines. Conversely, during economic downturns, prices may stabilize or decrease due to reduced demand.

6. Support and Service The level of after-sales support and service offered by the manufacturer is another crucial aspect influencing price. Machines that come with comprehensive service packages, including maintenance, training, and prompt technical assistance, may be more expensive upfront but can save manufacturers significant costs in downtime and repairs over time.

Price Range

The price of high-quality thread rolling machines can vary widely. Basic models suitable for small operations might start at around $10,000, while more advanced machines can range from $50,000 to over $200,000. Factors such as the ones mentioned earlier will ultimately dictate where a specific machine falls within this range. Additionally, it's advisable for prospective buyers to consider not just the initial purchase price but also the total cost of ownership, which includes operational costs, maintenance, and downtime.

Conclusion

In conclusion, the pricing of high-quality thread rolling machines is influenced by various factors, including machine quality, specifications, size, market trends, and after-sales support. As manufacturers continue to seek solutions that enhance efficiency and maintain high-quality output, knowledge of these pricing dynamics becomes essential for making informed purchasing decisions. Investing in the right thread rolling machine can lead to significantly improved operational efficiencies and product quality, proving to be a strategic advantage in today's competitive manufacturing landscape.