-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

high quality thread rolling machine price

Understanding the Price of High-Quality Thread Rolling Machines

Thread rolling machines play a crucial role in the manufacturing industry, especially in the production of high-quality fasteners, screws, and other threaded products. These machines are engineered to create cold-formed parts with superior dimensional accuracy and surface finish compared to traditional machining processes. As industries reflect on the effectiveness and efficiency of their production methods, the demand for high-quality thread rolling machines has escalated. However, a pressing question remains what drives the price of these machines?

Factors Influencing the Price

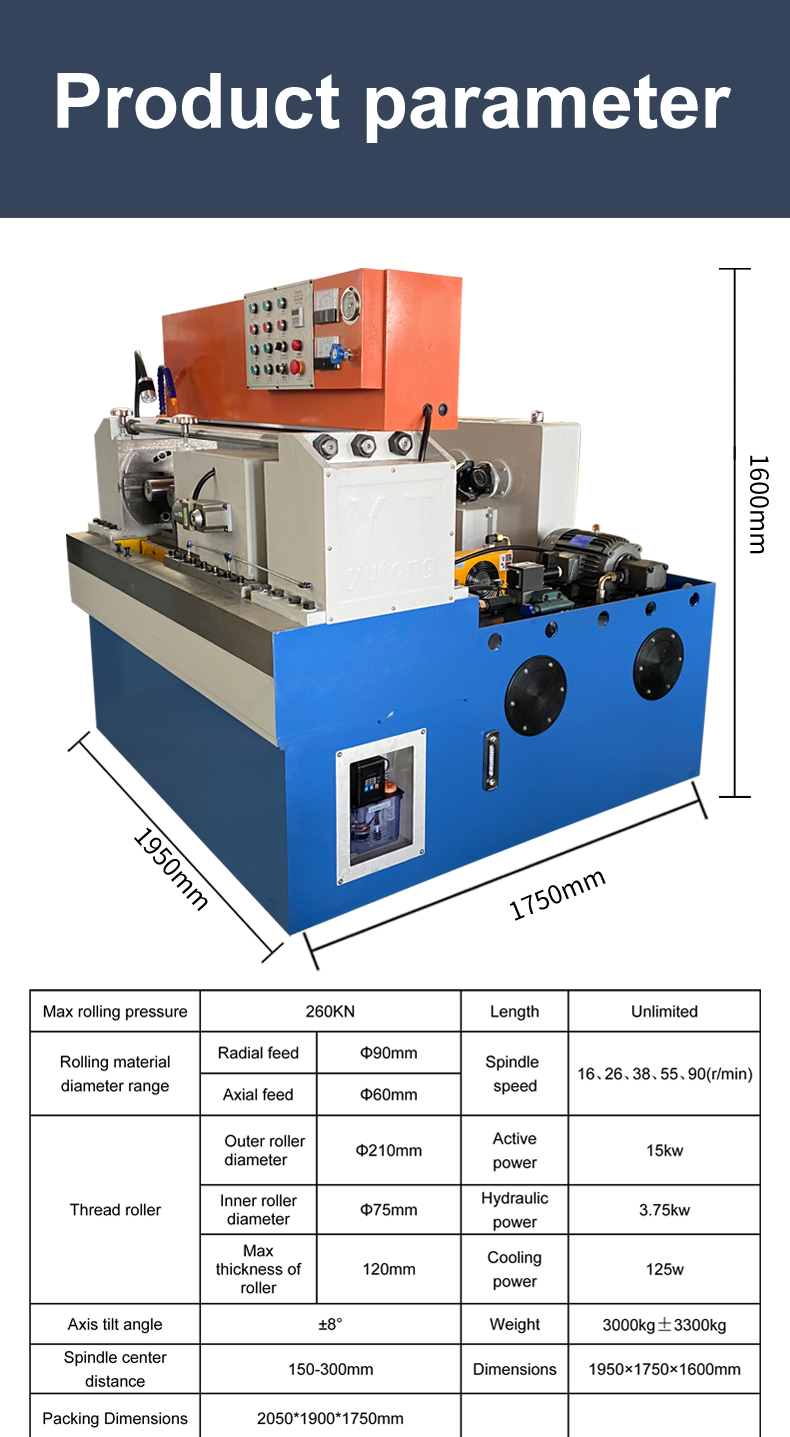

1. Machine Specifications High-quality thread rolling machines come with distinct specifications that cater to various manufacturing needs. Machines capable of handling larger diameters, higher production rates, or specific types of threads typically command higher prices. For example, a machine that can roll fine threads with precision will often be more expensive than a basic model designed for standard-sized threads.

2. Construction and Materials The durability, longevity, and performance of a thread rolling machine heavily depend on its construction materials. Machines made from high-grade steel and other robust materials will naturally be priced higher. This investment pays off in the long run, as they tend to require less maintenance and exhibit longer service lives, resulting in lower total operational costs.

3. Technology and Automation In today’s rapidly advancing technological landscape, automation has become a vital aspect of thread rolling machinery. Machines equipped with advanced features such as computer numerical control (CNC), integrated software for operational efficiency, and smart technology for predictive maintenance come at a premium price. Although the initial investment is higher, the enhanced productivity and reduced labor costs contribute to overall savings.

4. Manufacturer Reputation The reputation of the manufacturer also plays a significant role in pricing. Established brands known for their reliability and innovation may charge more than lesser-known manufacturers. In many cases, investing in a well-regarded brand ensures better support and service, a critical factor for businesses that rely on these machines for their operations.

high quality thread rolling machine price

5. Market Demand and Supply Conditions Like any other commodity, the price of thread rolling machines is influenced by market dynamics. High demand for these machines, especially in boom periods of manufacturing sectors like automotive and aerospace, can drive prices up. Conversely, a downturn in these industries may lead to lower demand, impacting pricing structures.

6. Additional Features and Customization Many manufacturers offer customizations to meet specific client needs, which can also affect pricing. Additional features such as multiple rolling heads for simultaneous production, automatic feeding systems, and tooling adjustments can increase the overall cost but often result in greater efficiency and flexibility.

Price Ranges

To provide a general outlook, the prices of high-quality thread rolling machines can vary significantly. Basic models may start around $10,000, while advanced machinery can exceed $100,000, depending on the factors discussed previously. Businesses must carefully evaluate their production needs, budget constraints, and potential return on investment (ROI) before making a purchasing decision.

Conclusion

In conclusion, understanding the price of high-quality thread rolling machines involves considering a multitude of factors, including specifications, materials, technology, and market conditions. While the initial investment may seem considerable, the long-term benefits of improved efficiency, reduced waste, and enhanced product quality often justify the expense. As industries continue to evolve and demand precision-engineered components, investing in a premium thread rolling machine can be a strategic move that sets a business apart in a competitive market. By making informed choices, manufacturers can not only enhance their production capabilities but also ensure sustainable growth in the long run.