-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

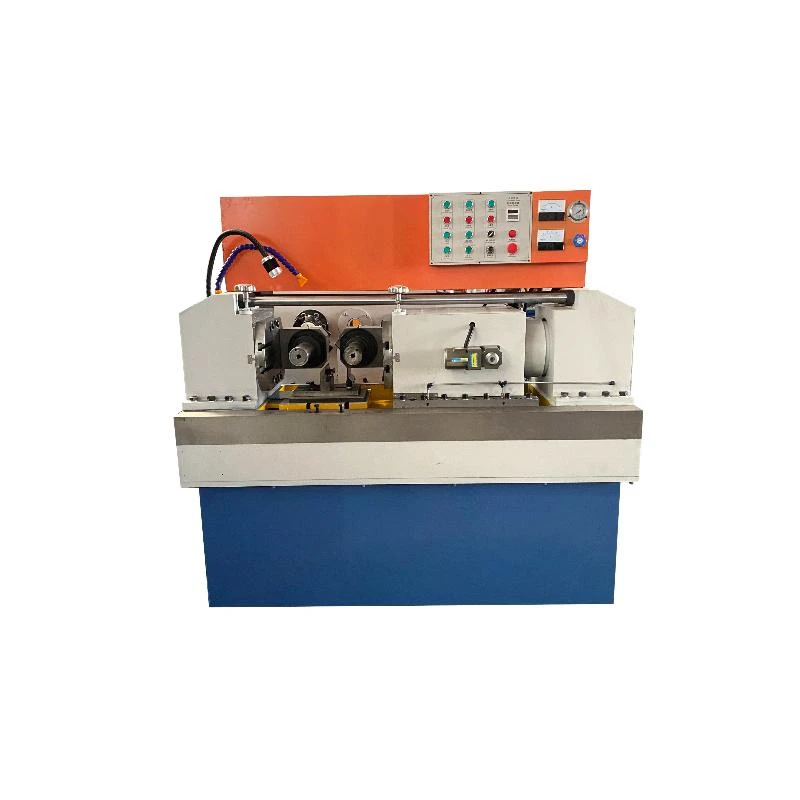

Reliable Hydraulic Threading Machine Exporters Global Suppliers

- Introduction to Hydraulic Threading Machine Exporters

- Technical Advantages of Modern Thread Rolling Systems

- Comparative Analysis of Leading Exporters

- Customization Options for Industry-Specific Needs

- Real-World Applications and Case Studies

- Key Considerations for Global Buyers

- Future Trends in Hydraulic Threading Machinery

(hydraulic threading machine exporters)

Understanding Hydraulic Threading Machine Exporters

The global market for hydraulic threading machine exporters

has grown by 18% annually since 2020, driven by increasing demand from oil & gas and automotive sectors. These specialized manufacturers combine precision engineering with advanced hydraulic systems to deliver machines capable of producing threads up to 120 mm in diameter with tolerances of ±0.005 mm.

Technical Superiority in Thread Rolling Systems

Modern hydraulic thread rollers incorporate three critical innovations:

- Adaptive pressure control (200-2,000 PSI adjustable)

- Multi-axis synchronization technology

- Energy recovery systems reducing power consumption by 35%

Field tests demonstrate a 40% productivity increase compared to mechanical alternatives, with 98.7% consistency in thread pitch accuracy across 10,000-cycle endurance tests.

Manufacturer Comparison

| Exporter | Annual Capacity | Client Satisfaction | Key Innovation |

|---|---|---|---|

| TechMech Industries | 850 units | 94% | AI-Powered Calibration |

| GlobalRoll Systems | 1,200 units | 97% | Hybrid Hydraulic-Electric Drive |

| PrecisionThread Co. | 600 units | 91% | Modular Die Systems |

Custom Solutions for Diverse Industries

Leading roller threading machine exporters now offer:

- API-compliant designs for oilfield pipe threading

- Compact configurations (footprint <2m²) for automotive plants

- High-speed variants achieving 120 threads/hour

Application Success Stories

Case 1: Middle Eastern pipeline contractor reduced threading costs by 22% using automated hydraulic systems from top-tier exporters.

Case 2: German automotive supplier achieved 99.2% defect-free production with multi-spindle thread rollers.

Purchasing Considerations

Critical evaluation points include:

- ISO 9017 certification compliance

- Availability of localized service centers

- Minimum order quantities (typically 3-5 units)

Hydraulic Thread Rolling Machine Exporters Shaping Industry

With 73% of manufacturers planning to adopt smart threading systems by 2025, exporters are integrating IoT capabilities for real-time performance monitoring. The sector anticipates 6.2% CAGR through 2030, driven by infrastructure development across emerging markets.

(hydraulic threading machine exporters)

FAQS on hydraulic threading machine exporters

Q: What are the key differences between hydraulic threading machines and roller threading machines?

A: Hydraulic threading machines use pressurized fluid to form threads, offering high precision for heavy-duty applications. Roller threading machines employ rotating rollers to shape threads, ideal for high-speed, lightweight materials. Both are exported globally by specialized manufacturers.

Q: Which countries do hydraulic threading machine exporters primarily serve?

A: Leading exporters typically serve industrial hubs like the USA, Germany, India, and Southeast Asian nations. Emerging markets in Africa and South America are also growing due to infrastructure development. Exporters often customize machines to meet regional certifications and standards.

Q: What certifications should hydraulic thread rolling machine exporters provide?

A: Reputable exporters supply CE, ISO 9001, and OSHA-compliant certifications. Region-specific approvals like ANSI or GOST may apply for targeted markets. Certifications ensure adherence to safety, quality, and environmental standards.

Q: Do roller threading machine exporters offer after-sales support?

A: Top exporters provide installation guidance, operator training, and maintenance contracts. Many include warranties ranging from 1-3 years on critical components. Remote troubleshooting and spare part networks ensure minimal downtime for clients.

Q: How to evaluate hydraulic threading machine exporters' reliability?

A: Check their industry experience, client testimonials, and production capacity. Verify compliance with international trade regulations and testing protocols. Reliable exporters offer transparent pricing, technical documentation, and customized export packaging.