-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

hydraulic threading machine manufacturer

The Significance of Hydraulic Threading Machines in Modern Manufacturing

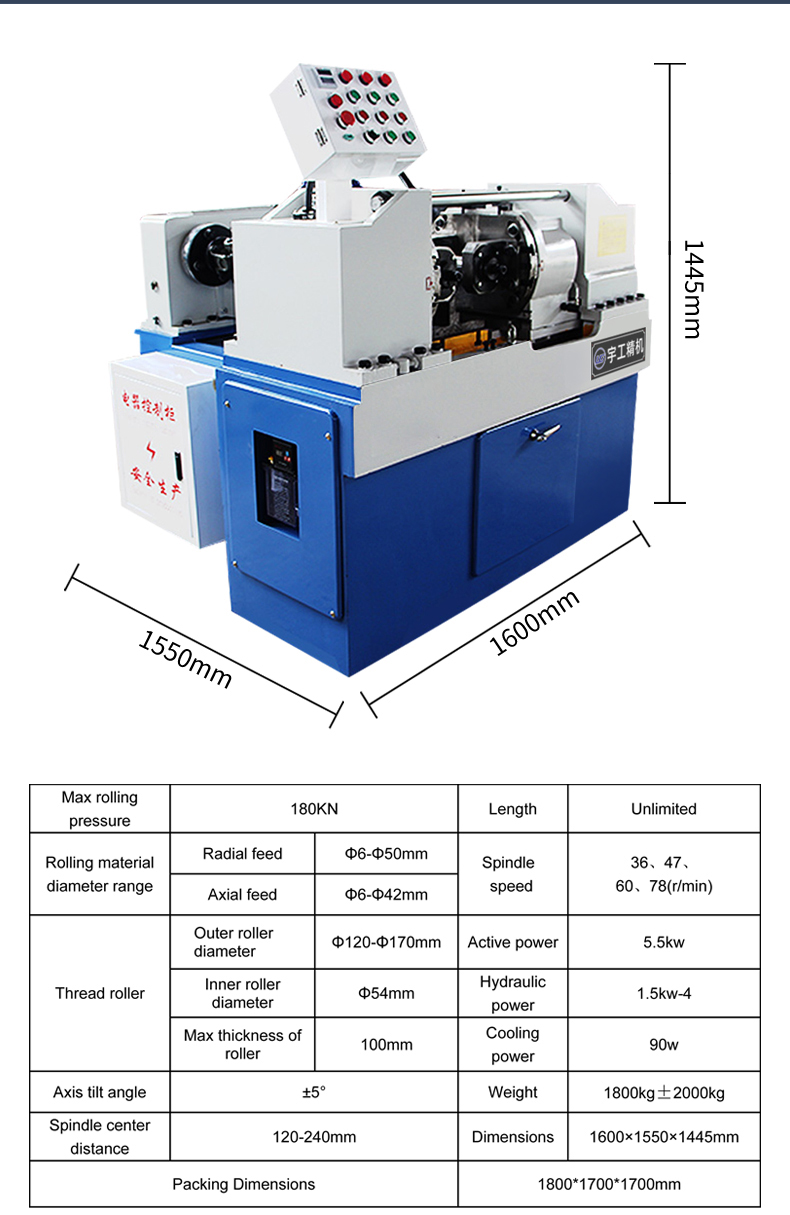

In the world of manufacturing, the need for precision and efficiency is paramount. One key player in achieving these objectives is the hydraulic threading machine. This advanced machinery has revolutionized the way threads are created, allowing for faster, more reliable, and accurate production processes. When examining the contributions of hydraulic threading machine manufacturers, it becomes evident that their innovations are crucial to various industries, including construction, aviation, and automotive sectors.

Hydraulic threading machines utilize hydraulic power to generate the torque needed for cutting threads into metal or plastic materials. This technology results in a smoother operation compared to traditional threading machines, which rely on mechanical gears and levers. The hydraulic system minimizes wear and tear on the equipment, reducing maintenance costs and downtime. Furthermore, the consistent torque delivered by hydraulic systems allows for more uniform thread profiles, which is essential for the integrity and performance of threaded components.

One of the primary advantages of hydraulic threading machines is their ability to handle a wide range of materials and sizes. Manufacturers can produce threads on pipes, rods, and various fittings without the constraints often imposed by manual threading techniques. This versatility is particularly advantageous in industries that deal with diverse materials and specifications. For instance, in the oil and gas sector, the ability to create robust and precise threads in high-strength steel is vital for the reliability of drilling equipment.

hydraulic threading machine manufacturer

Moreover, modern hydraulic threading machines are often equipped with advanced control systems that enhance productivity. These systems enable operators to set parameters for speed, force, and thread type accurately. Many machines also feature automation, allowing for repetitive tasks to be performed with minimal human intervention. This not only improves the efficiency of the threading process but also reduces the risk of human error, which can lead to costly rework and material waste.

The rise of hydraulic threading machine manufacturers has also spurred innovation in ancillary technologies. This includes enhancements in tool design, customization options, and the integration of smart technologies such as IoT for predictive maintenance. As the industry moves towards a more automated future, the role of these manufacturers becomes even more significant in bridging the gap between traditional practices and modern requirements.

In conclusion, hydraulic threading machines represent a vital advancement in manufacturing technology. They offer increased efficiency, versatility, and precision, making them indispensable in various sectors. Manufacturers dedicated to producing hydraulic threading machines continue to push the boundaries of what is possible, ensuring that industries can meet the ever-growing demand for high-quality, reliable threaded components. As the landscape of manufacturing continues to evolve, hydraulic threading machines will undoubtedly play a pivotal role in shaping its future.