-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

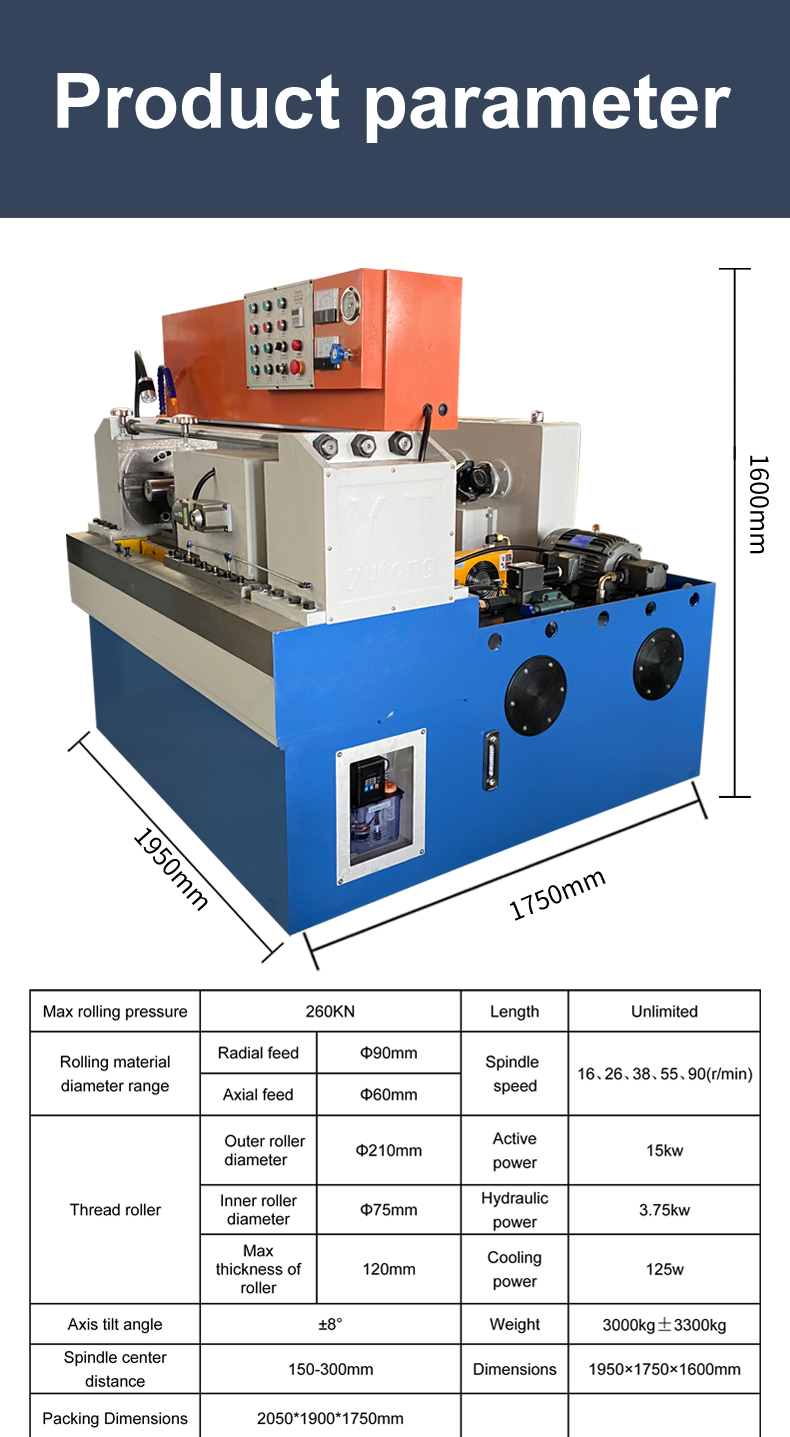

Top Manufacturers of Hydraulic Threading Machines for Your Industrial Needs

The Evolution and Importance of Hydraulic Threading Machines in Manufacturing

In the manufacturing sector, precision and efficiency are paramount. Among the critical tools that ensure these objectives are met are hydraulic threading machines. These machines are designed to create threads on various materials with high accuracy and speed, making them indispensable in numerous industries, from plumbing to construction.

Hydraulic threading machines utilize hydraulic power to perform threading operations, offering several advantages over traditional manual methods. The mechanism of these machines relies on fluid power, which provides greater force and control. This results in cleaner threads and minimizes the risk of errors that often occur when threads are cut manually. As a result, hydraulic threading machines not only enhance production efficiency but also improve the overall quality of the end product.

The manufacturers of hydraulic threading machines have been continually innovating to meet the evolving needs of industries. Advancements in technology have led to the development of machines that are more compact and user-friendly, while still delivering robust performance. Modern hydraulic threading machines are equipped with automated features, such as programmable controls and digital displays, which allow operators to set precise threading parameters quickly. This not only saves time but significantly reduces the potential for human error.

The importance of these machines extends beyond mere efficiency. In industries where the integrity of the threaded connections is vital—such as in oil and gas or aerospace—having the right threading equipment can be a matter of safety and functionality. Hydraulic threading machines can produce threads that meet stringent industry standards, ensuring that components fit together seamlessly and function as intended.

hydraulic threading machine manufacturers

Moreover, the versatility of hydraulic threading machines makes them suitable for a wide array of materials, including steel, aluminum, and plastic. This versatility is crucial for manufacturers who require flexibility in their operations to adapt to different projects and materials. Many of today's hydraulic threading machines are designed to handle various sizes and types of pipes and fittings, further enhancing their utility in different manufacturing scenarios.

As we look to the future, the trend towards automation and digital integration continues to influence the design of hydraulic threading machines. Smart technology is becoming increasingly prevalent in manufacturing equipment, allowing for more efficient monitoring and maintenance. For instance, predictive maintenance can reduce downtime by alerting operators to potential issues before they become serious problems. This proactive approach to machine management not only extends the life of the equipment but also enhances overall productivity.

Another emerging trend in the field is the emphasis on sustainability. Manufacturers are increasingly aware of their environmental impact and are seeking machines that consume less energy and produce less waste. Hydraulic threaders that use energy-efficient designs and materials contribute to a greener production process, aligning with global efforts to reduce carbon footprints.

In conclusion, hydraulic threading machines represent a critical component of modern manufacturing. With their ability to provide precision, speed, and versatility, they are essential in ensuring high-quality outcomes in various industries. As manufacturers continue to innovate and improve these machines, we can expect to see even greater advancements in efficiency, automation, and sustainability in the future. Companies looking to invest in hydraulic threading machines should choose reputable manufacturers who prioritize quality and technological advancement, ensuring they remain competitive in an ever-evolving marketplace.