-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

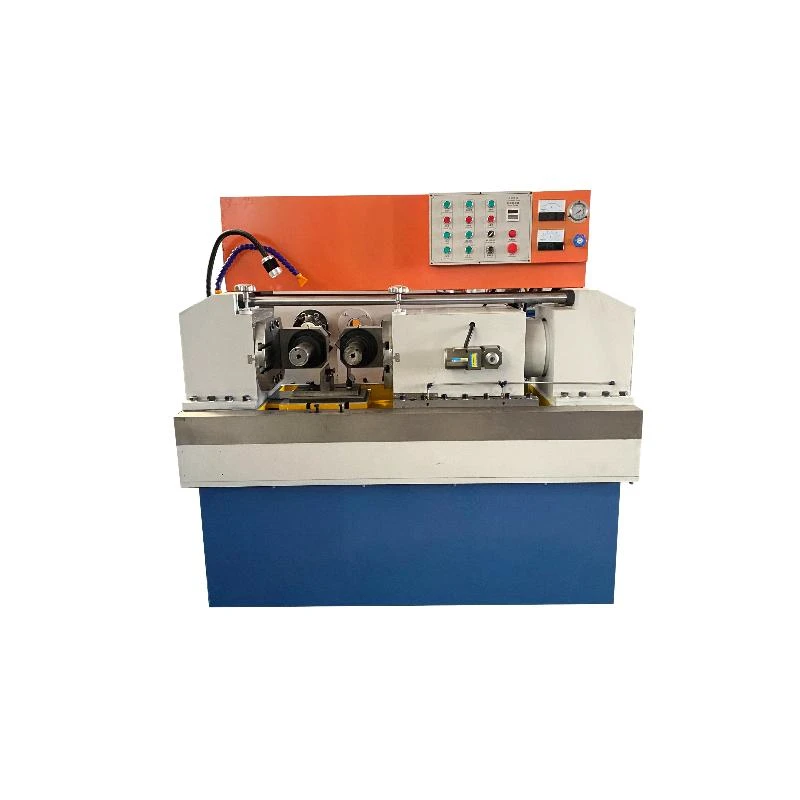

Hydraulic Threading Machine Cost and Specifications for Your Business Needs

Understanding the Hydraulic Threading Machine Price List

In the realm of industrial equipment, hydraulic threading machines occupy a crucial role, particularly in pipe fitting and plumbing applications. These machines are engineered to create precise threads on pipes, ensuring secure and leak-proof connections. As the demand for reliable and efficient machinery rises, understanding the pricing landscape of hydraulic threading machines becomes essential for businesses and professionals alike.

Factors Influencing Price

Several factors contribute to the pricing of hydraulic threading machines. First and foremost is the brand reputation. Established manufacturers that have a history of producing high-quality, durable machinery often set higher price points due to the reliability and after-sales support they provide. On the other hand, lesser-known brands might offer more competitive pricing, but this could come at the cost of quality and support.

Machine Specifications also play a significant role in determining price. Machines that can handle a larger range of pipe sizes, deliver faster threading speeds, and include advanced features such as programmable settings or automatic lubrication systems generally come at a premium. For instance, a basic model capable of threading standard sizes may be more budget-friendly compared to an advanced machine designed for heavy-duty use with multiple functionalities.

Additionally, materials used in construction affect pricing. Hydraulic threading machines made from high-quality materials that enhance durability and reduce wear and tear are often priced higher. In contrast, machines constructed from lower-grade materials might be more affordable but could result in increased maintenance costs over time.

Typical Price Range

The price range of hydraulic threading machines can vary widely. Entry-level models suitable for small scale operations can start around $1,500, offering basic functionality for threading smaller pipes. Medium-range machines, which come equipped with better features and increased pipe handling capabilities, typically fall between $3,000 and $6,000. High-end machines, designed for industrial applications and capable of threading large diameter pipes or incorporating advanced technologies, can range from $7,000 to over $20,000.

hydraulic threading machine pricelist

Additional Costs

Purchasing a hydraulic threading machine involves considering additional costs beyond the initial price. Maintenance and repairs should be factored in, as regular servicing is vital to ensure the longevity and performance of the machine. Businesses should also consider the cost of accessories and consumables, such as cutting dies and lubricants, which are necessary for optimal operation.

Moreover, training costs should not be overlooked. Proper operation of hydraulic threading machines requires skilled personnel. Investing in employee training can enhance safety and efficiency, making it an essential aspect of budgeting.

Making an Informed Decision

When choosing the right hydraulic threading machine, potential buyers should take their specific needs into account. Understanding the typical applications, required threading capacities, and long-term operational cost implications is critical.

Comparing different models and their specifications will allow buyers to find a machine that not only fits their budget but also meets their operational demands. Additionally, looking for customer reviews and testimonies can provide insights into the reliability and performance of various brands and models.

In conclusion, while the price list for hydraulic threading machines may seem daunting, a thoughtful approach that considers various factors can lead to a wise investment. Whether you are a contractor, plumber, or industrial operator, selecting the right hydraulic threading machine can significantly impact your efficiency, productivity, and ultimately, your bottom line.