-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 14, 2025 09:00

Back to list

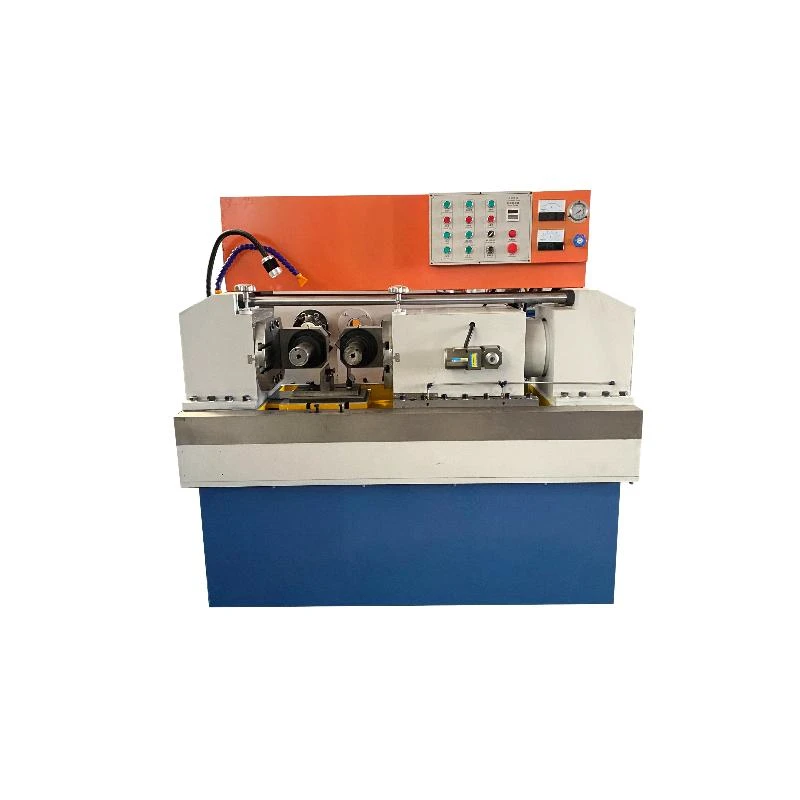

hydraulic threading machine products

Navigating the world of hydraulic threading machine products requires both expertise and understanding of industry demands. As technology advances, the landscape of mechanical engineering continues to shift, bringing innovations that revolutionize production processes. This article delves into the intricacies of hydraulic threading machines, exploring their benefits, applications, and the considerations buyers must keep in mind.

Trustworthiness in the realm of hydraulic threading machines also relates to the availability of after-sales service and support. Companies that provide comprehensive training, technical support, and spare parts supply ensure their clients experience minimal downtime. Investing in a product from a manufacturer that provides extensive customer support drastically reduces operational risks and enhances the user's peace of mind. After all, the ability to promptly and efficiently address any technical issues greatly impacts operational continuity and project timelines. Applications of hydraulic threading machines span multiple industries, including oil and gas, construction, and automotive sectors. In oil and gas, for instance, threading accuracy is critical, as pipeline integrity must be uncompromised to prevent leaks and environmental hazards. Precision and reliability of hydraulic threading machines facilitate the construction of pipelines that meet these stringent demands. In construction, threaded rods and pipes are essential for creating strong, stable structures, while in the automotive industry, precision threading ensures that components fit perfectly, enhancing vehicle safety and performance. The decision to invest in a hydraulic threading machine should be grounded in assessing specific operational needs and evaluating the machine's capabilities. Potential buyers should consider factors such as the machine's threading speed, range of compatibility with different materials, ease of use, and maintenance requirements. Additionally, it's important to calculate the return on investment by considering the machine's impact on productivity and labor costs. In conclusion, hydraulic threading machines represent a significant advancement in the field of mechanical engineering, offering unparalleled precision, efficiency, and reliability. Their importance across various industries cannot be understated, as they streamline production processes, reduce costs, and enhance safety. With proper expertise and investment in quality machines, businesses can harness the full potential of hydraulic threading technology, maintaining a competitive edge in their respective markets.

Trustworthiness in the realm of hydraulic threading machines also relates to the availability of after-sales service and support. Companies that provide comprehensive training, technical support, and spare parts supply ensure their clients experience minimal downtime. Investing in a product from a manufacturer that provides extensive customer support drastically reduces operational risks and enhances the user's peace of mind. After all, the ability to promptly and efficiently address any technical issues greatly impacts operational continuity and project timelines. Applications of hydraulic threading machines span multiple industries, including oil and gas, construction, and automotive sectors. In oil and gas, for instance, threading accuracy is critical, as pipeline integrity must be uncompromised to prevent leaks and environmental hazards. Precision and reliability of hydraulic threading machines facilitate the construction of pipelines that meet these stringent demands. In construction, threaded rods and pipes are essential for creating strong, stable structures, while in the automotive industry, precision threading ensures that components fit perfectly, enhancing vehicle safety and performance. The decision to invest in a hydraulic threading machine should be grounded in assessing specific operational needs and evaluating the machine's capabilities. Potential buyers should consider factors such as the machine's threading speed, range of compatibility with different materials, ease of use, and maintenance requirements. Additionally, it's important to calculate the return on investment by considering the machine's impact on productivity and labor costs. In conclusion, hydraulic threading machines represent a significant advancement in the field of mechanical engineering, offering unparalleled precision, efficiency, and reliability. Their importance across various industries cannot be understated, as they streamline production processes, reduce costs, and enhance safety. With proper expertise and investment in quality machines, businesses can harness the full potential of hydraulic threading technology, maintaining a competitive edge in their respective markets.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025