-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

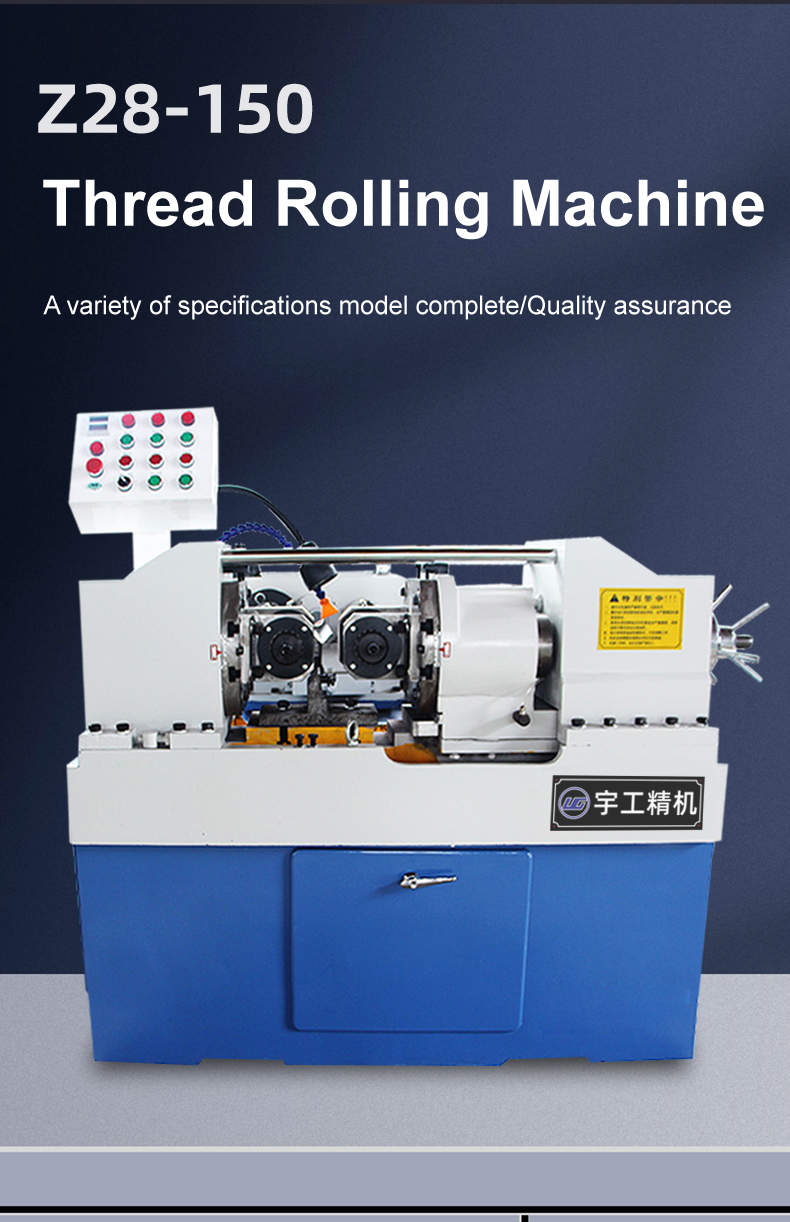

hydraulic thread rolling machine factory

The Hydraulic Thread Rolling Machine Factory Revolutionizing Manufacturing Processes

In the modern manufacturing landscape, the demand for precision and efficiency continues to escalate. At the forefront of this evolution is the hydraulic thread rolling machine factory, a critical player in producing high-quality threaded components that are indispensable in various industries. This factory not only exemplifies advanced manufacturing techniques but also adheres to stringent quality standards, ensuring that products meet the needs of an increasingly demanding market.

Hydraulic thread rolling machines are specifically designed to produce threads through a cold forming process. This innovative method utilizes high pressure to shape and mold materials, typically metal, into the desired threaded form without any cutting. This process not only retains the metal's integrity by minimizing waste but also enhances the strength of the finished product. As such, industries requiring robust and durable parts—such as automotive, aerospace, and construction—have increasingly turned to hydraulic thread rolling due to its superior results.

What sets a hydraulic thread rolling machine factory apart is its ability to streamline production. These factories employ state-of-the-art technology that integrates automation and precision engineering. Advanced computer numerical control (CNC) systems allow for high levels of customization and repeatability in manufacturing processes, ensuring that each component produced meets exact specifications. This level of automation not only increases productivity but also significantly reduces the likelihood of human error, leading to improved product quality.

hydraulic thread rolling machine factory

Moreover, the hydraulic thread rolling process is highly versatile, accommodating a wide range of materials, including steel, aluminum, and other alloys. The flexibility in material selection enables manufacturers to cater to diverse applications and industry requirements. For example, in the automotive sector, thread-rolled fasteners are essential for assembly processes, as they offer enhanced grip and load-bearing capabilities compared to conventional threaded components. The factory's capacity to produce various sizes and types of threads ensures that it can meet the specific needs of any project.

Another compelling aspect of the hydraulic thread rolling machine factory is its commitment to sustainability. By utilizing a cold forming technique, these factories significantly reduce energy consumption and waste generation compared to traditional machining processes. This commitment to environmental responsibility not only aligns with global sustainability goals but also appeals to clients who prioritize eco-friendly manufacturing practices.

Quality control is paramount in the operations of the hydraulic thread rolling machine factory. Rigorous testing and inspection processes are implemented to guarantee that every product adheres to international quality standards. Advanced measuring systems, including laser measurement technology, ensure that dimensions and thread profiles meet strict tolerances. This dedication to quality not only builds trust with customers but also establishes a reputation for excellence in the competitive manufacturing landscape.

In conclusion, the hydraulic thread rolling machine factory stands as a beacon of advanced manufacturing technology. Through its innovative processes, commitment to quality, and sustainable practices, it plays a vital role in providing industries with the critical components they need for a wide range of applications. As the demand for high-quality threaded products continues to grow, so too will the importance of these specialized factories in meeting the challenges of modern manufacturing. With their focus on efficiency, precision, and environmental sustainability, hydraulic thread rolling machine factories are indeed revolutionizing the way we think about manufacturing.