-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

hydraulic thread rolling machine price company

The Market for Hydraulic Thread Rolling Machines Pricing and Key Players

In the realm of manufacturing and industrial operations, the necessity for precise and efficient processes is paramount. One crucial aspect of manufacturing threaded components lies in the production methods employed. Hydraulic thread rolling machines have emerged as a preferred technology for creating high-quality threads due to their ability to enhance production efficiency, improve thread quality, and reduce waste. As demand for these machines grows, so does the interest in understanding their pricing and the leading companies in the market.

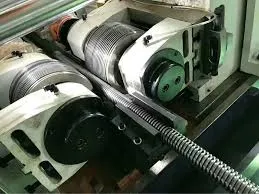

Understanding Hydraulic Thread Rolling Machines

Hydraulic thread rolling machines are specialized equipment used to create threads on various metallic materials through a process called thread rolling. This method employs high pressure and rolling dies to achieve the desired thread shape and dimension. The advantages of using hydraulic systems include better control over the rolling process, increased force application, and the ability to work with a variety of materials. These machines are pivotal in industries such as automotive, aerospace, and general manufacturing, where threaded components are essential.

Factors Influencing Pricing

The price of hydraulic thread rolling machines can vary significantly based on multiple factors

1. Machine Specifications Size, capacity, and the type of hydraulic system used are critical determinants. Machines designed for heavy-duty applications or those that can handle larger diameters usually come at a premium.

2. Technology and Features Advanced features such as automatic feed systems, digital controls, energy efficiency, and enhanced safety mechanisms can increase the cost.

3. Brand Reputation Established companies with a history of quality and service often charge more for their machinery, reflecting their market position and reliability.

4. Customization Options Some manufacturers offer customizable machines tailored to specific production needs. These bespoke solutions typically involve a higher investment.

5. Market Trends and Demand Fluctuations in demand and raw material costs can influence machine pricing. A surge in the automotive or aerospace industry, for instance, might drive prices up due to heightened demand for high-precision threads.

hydraulic thread rolling machine price company

6. Maintenance and Support A machine's long-term cost includes maintenance and after-sales service, which should be factored into the overall pricing consideration.

Key Players in the Hydraulic Thread Rolling Machine Market

As the market expands, several key companies have established themselves as leaders in the production of hydraulic thread rolling machines. Here are a few notable players

1. Rivett & William Known for their industrial machinery, they have a robust lineup of hydraulic thread rolling machines that deliver precision and durability.

2. Amardeep Steel Centre Specializing in various manufacturing solutions, they offer a range of hydraulic thread rollers known for their reliability and efficiency.

3. CNC Machinery Focused on advanced technology, CNC Machinery provides high-end hydraulic machines with automated features, catering to the modern manufacturing sector.

4. Eagle Machinery A well-regarded manufacturer, Eagle Machinery produces user-friendly and cost-effective hydraulic thread rolling machines suitable for small to medium-sized enterprises.

5. National Machinery A significant player in the market, offering advanced technology and a wide array of machines to meet diverse needs, National Machinery's products are well-regarded for their engineering excellence.

Conclusion

The hydraulic thread rolling machine market is an evolving landscape marked by continuous advancements in technology and growing demand across various industries. Prices are influenced by an array of factors, including machine specifications, brand reputation, and customization options. For businesses looking to invest in these machines, it is vital to evaluate not only the initial purchase price but also the long-term operational costs, including maintenance and support.

As the industry progresses, staying informed about market trends and the offerings of key players will empower manufacturers to make well-informed decisions that align with their production needs and economic considerations. As such, a strategic approach is not only to seek the best price but to ensure the machine meets the required quality standards and contributes positively to the overall production efficiency.