-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Hydraulic Thread Rolling Machine Cost and Product Overview for Industry Buyers

Understanding the Price Factors for Hydraulic Thread Rolling Machines

Hydraulic thread rolling machines are essential tools in various manufacturing sectors, especially in the production of fasteners and precision components. These machines create threads on metal rods through a process that involves rolling rather than cutting, which enhances material strength and surface finish. As industries continue to expand, the demand for efficient and reliable machinery increases, raising the question what influences the price of hydraulic thread rolling machines?

One of the primary factors affecting the price of hydraulic thread rolling machines is their design and complexity. Basic models can be relatively affordable, but as the need for advanced features grows—such as programmable controls, increased production capacity, and enhanced automation—the cost rises significantly. Advanced machines often come equipped with software that allows for precise adjustments and monitoring, which not only improves efficiency but also reduces labor costs over time.

Another crucial element is the machine's build quality and the materials used in its construction. High-quality machines made from durable, wear-resistant materials are more expensive but can offer a longer lifespan and lower maintenance costs. Investing in a well-built machine can pay off in the long run, as it may result in fewer downtimes and repairs.

hydraulic thread rolling machine price product

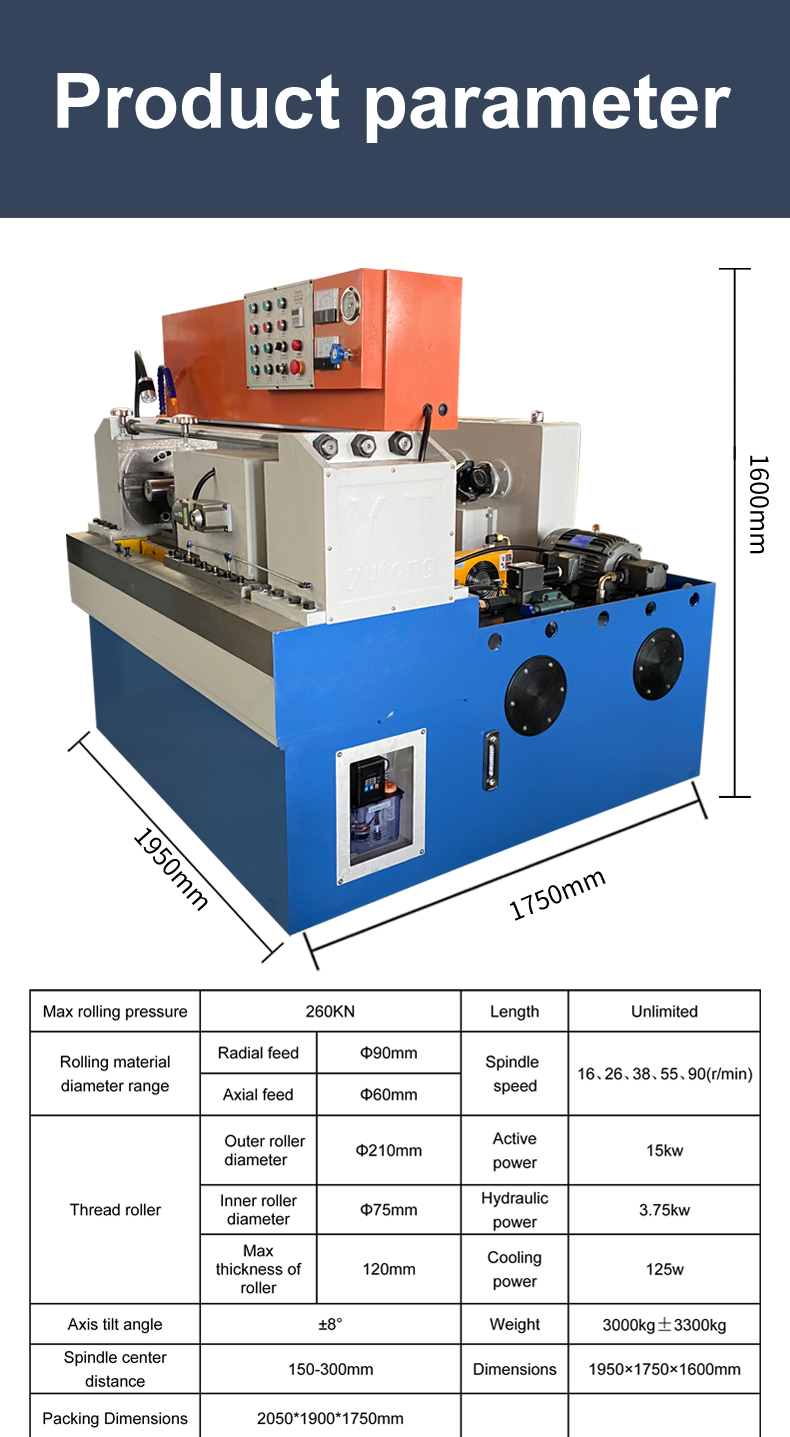

The capacity and specifications of the hydraulic thread rolling machine also play a significant role in determining its price. Machines designed to handle larger workpieces or produce threads in a wider range of gauges typically come at a premium. Manufacturers must assess their production needs and make decisions based on the types of materials they will work with and the complexity of the threading required.

Moreover, the brand reputation and after-sales support can significantly influence pricing. Established manufacturers with a proven track record often charge more due to their reliability and the quality assurance they provide. Additionally, warranty options and the availability of spare parts from the manufacturer should be considered, as they can contribute to long-term operating costs.

Lastly, market dynamics such as supply chain conditions, currency fluctuations, and regional manufacturing capabilities can impact the price of these machines. For instance, disruptions in the supply chain may lead to increased costs for raw materials, which in turn can raise the prices of hydraulic thread rolling machines.

In conclusion, when evaluating the price of hydraulic thread rolling machines, it’s essential to consider various factors including design complexity, build quality, capacity, brand reputation, and external market conditions. A well-informed purchase can enhance production efficiency and contribute to overall business success in sectors reliant on threaded components. As the industry evolves, staying updated on these factors will ensure that manufacturers make the best investment for their operational needs.