-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Hydraulic Thread Rolling Machine Cost and Supplier Information for Your Manufacturing Needs

The Pricing and Suppliers of Hydraulic Thread Rolling Machines

Hydraulic thread rolling machines play a crucial role in the manufacturing industry, especially when it comes to creating high-precision threads on various materials. These machines utilize hydraulic power to apply pressure and enable the rolling process, allowing manufacturers to produce superior quality threads compared to traditional machining methods. Understanding the pricing dynamics and the landscape of suppliers for these machines is essential for businesses aiming to integrate them into their production lines.

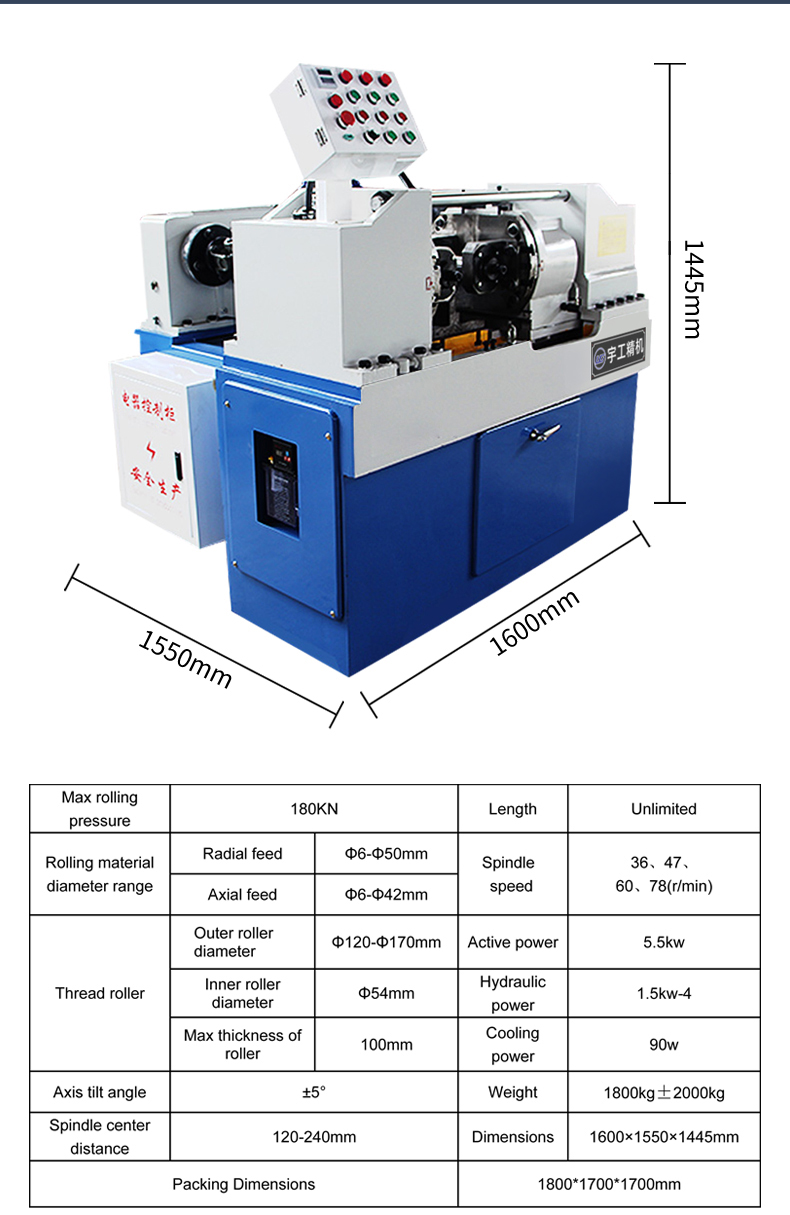

Understanding Hydraulic Thread Rolling Machines

Hydraulic thread rolling machines operate on the principle of cold forming, where metal threads are created without removing material. The process involves the use of cylindrical dies that compress the metal to form the desired thread profile. This method is not only efficient but also enhances the mechanical properties of the product, making it stronger and more durable. Applications include automotive, aerospace, construction, and general manufacturing sectors.

Pricing Factors

When it comes to the price of hydraulic thread rolling machines, several factors come into play

1. Machine Specifications The complexity and specifications of the machine have a significant impact on its price. Machines designed for high-volume production with advanced features, such as automatic loading and unloading systems, tend to be more expensive.

2. Brand Reputation Renowned manufacturers with established reputations often charge a premium for their machinery. Their products are usually backed by superior support, warranty, and technologically advanced features, making them a preferred choice for many companies.

3. Market Demand The demand for hydraulic thread rolling machines can fluctuate based on the economic landscape. During periods of industrial growth, prices may rise due to increased demand, while during downturns, prices might stabilize or decrease.

4. Supplier Relationships Businesses that establish long-term relationships with suppliers may negotiate better prices or receive discounts. Purchasing in bulk also tends to lower per-unit costs, making it economical for larger firms.

hydraulic thread rolling machine price suppliers

5. Location and Shipping Costs The geographical location of the supplier can affect the overall cost, especially when considering shipping and customs duties for international purchases. Local suppliers might offer significant advantages in terms of delivery times and reduced shipping costs.

Finding Reliable Suppliers

As the demand for hydraulic thread rolling machines continues to grow, the number of suppliers has increased, providing various options for manufacturers. Here are some strategies to find reliable suppliers

1. Research Online Platforms Websites like Alibaba, Made-in-China, and Global Sources are great resources for finding potential suppliers. They often provide user reviews and ratings, which can inform purchasing decisions.

2. Industry Trade Shows and Expositions Attending industry trade shows such as the International Manufacturing Technology Show (IMTS) or the Hannover Messe can provide direct access to manufacturers and suppliers. This exposure allows for hands-on evaluations and the opportunity to establish personal connections.

3. Industry Associations Membership in industry associations can also lead to better supplier networks. These associations often have directories of manufacturers and can provide recommendations based on reliability and quality.

4. Requesting Quotes and Proposals Once potential suppliers are identified, requesting detailed quotes can help compare pricing structures and features offered. This step is vital for ensuring that the chosen machine fits both operational needs and budget constraints.

5. After-Sales Support It's essential to consider after-sales support when choosing a supplier. Reliable technical support, availability of spare parts, and warranty terms can significantly affect the overall operational efficiency of the machines in the long run.

Conclusion

Hydraulic thread rolling machines represent a significant investment for manufacturers looking to enhance their operational capabilities. Understanding the pricing factors and identifying reliable suppliers is crucial for making informed purchasing decisions. As the market for these machines expands, staying informed about the latest innovations and supplier offerings will enable businesses to secure the best equipment for their needs. Engaging in thorough research and building strategic relationships with suppliers can lead to improved productivity and greater competitiveness in the manufacturing sector.