-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

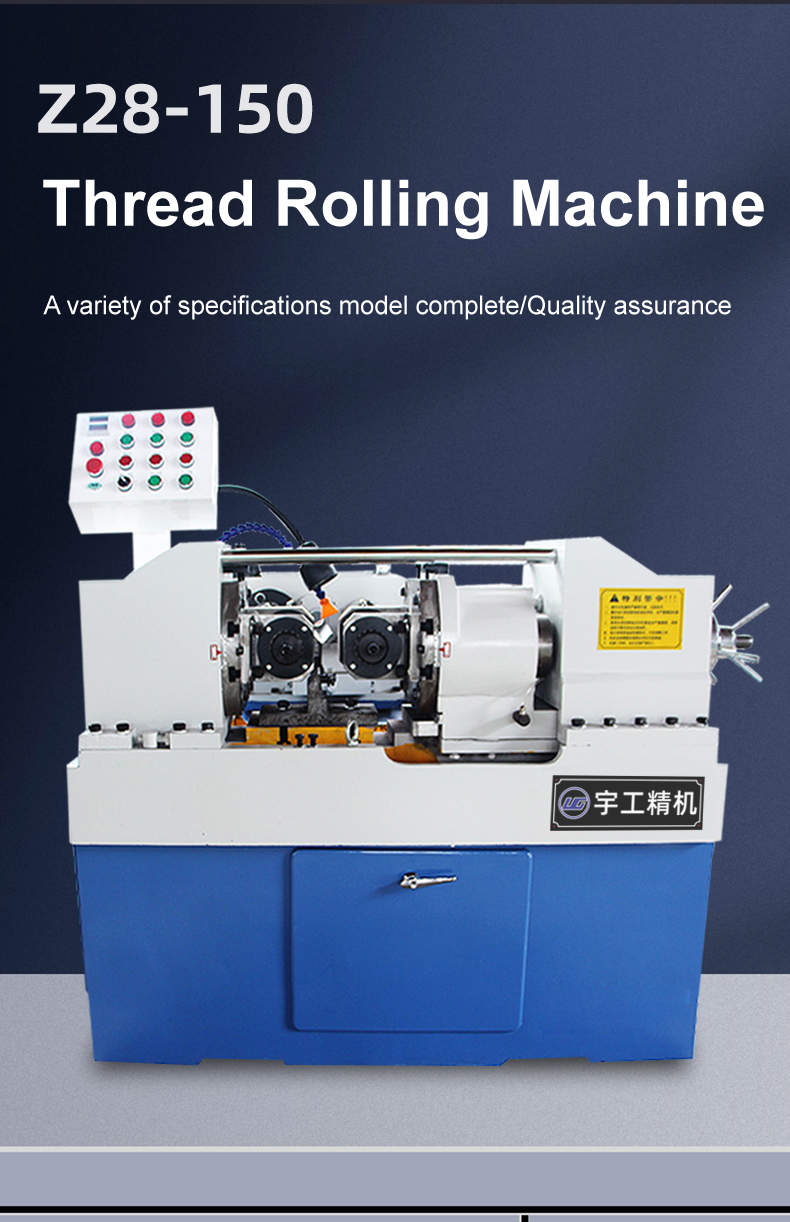

Machine for threading using rollersboosted thread quality and production efficiency.

A roller threading machine is a specialized piece of equipment used in the manufacturing industry to create threads on rods, pipes, and other cylindrical objects. This machine is essential for industries such as construction, automotive, and plumbing, where threaded components are frequently used.

The operation of a roller threading machine involves feeding the rod or pipe through a set of rollers that press against the material with enough force to create the desired thread pattern. The rollers have grooves or ridges that correspond to the thread pitch, allowing them to cut or deform the material as it passes through.

One of the main advantages of a roller threading machine is its ability to produce accurate and consistent threads quickly. This is important in industries where tight tolerances are required to ensure proper fit and functionality of threaded components. The machine can also be set up to produce different thread sizes and pitches, making it versatile for a variety of applications.

In addition to accuracy and speed, a roller threading machine is designed for efficiency and ease of use

. The machine is typically equipped with adjustable settings for thread depth, diameter, and pitch, allowing operators to fine-tune the threading process to meet specific requirements. Some machines also feature automatic feeding systems and cutting mechanisms to further streamline the production process.roller threading machine

Safety is another important consideration when using a roller threading machine. These machines are equipped with guards and sensors to protect operators from moving parts and cutting tools. Regular maintenance and inspection are also necessary to ensure that the machine is operating safely and efficiently.

Overall, a roller threading machine is a valuable investment for manufacturers looking to improve their production process and increase efficiency. By producing accurate and consistent threads quickly, this machine can help companies meet customer demands and maintain high-quality standards in their products.

In conclusion, a roller threading machine plays a critical role in the manufacturing industry by enabling the production of threaded components with precision and efficiency. With its ability to create accurate threads quickly and consistently, this machine is essential for various industries where threaded objects are commonly used. By investing in a roller threading machine, manufacturers can improve their production process and meet the demands of their customers effectively.