-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 10, 2025 08:53

Back to list

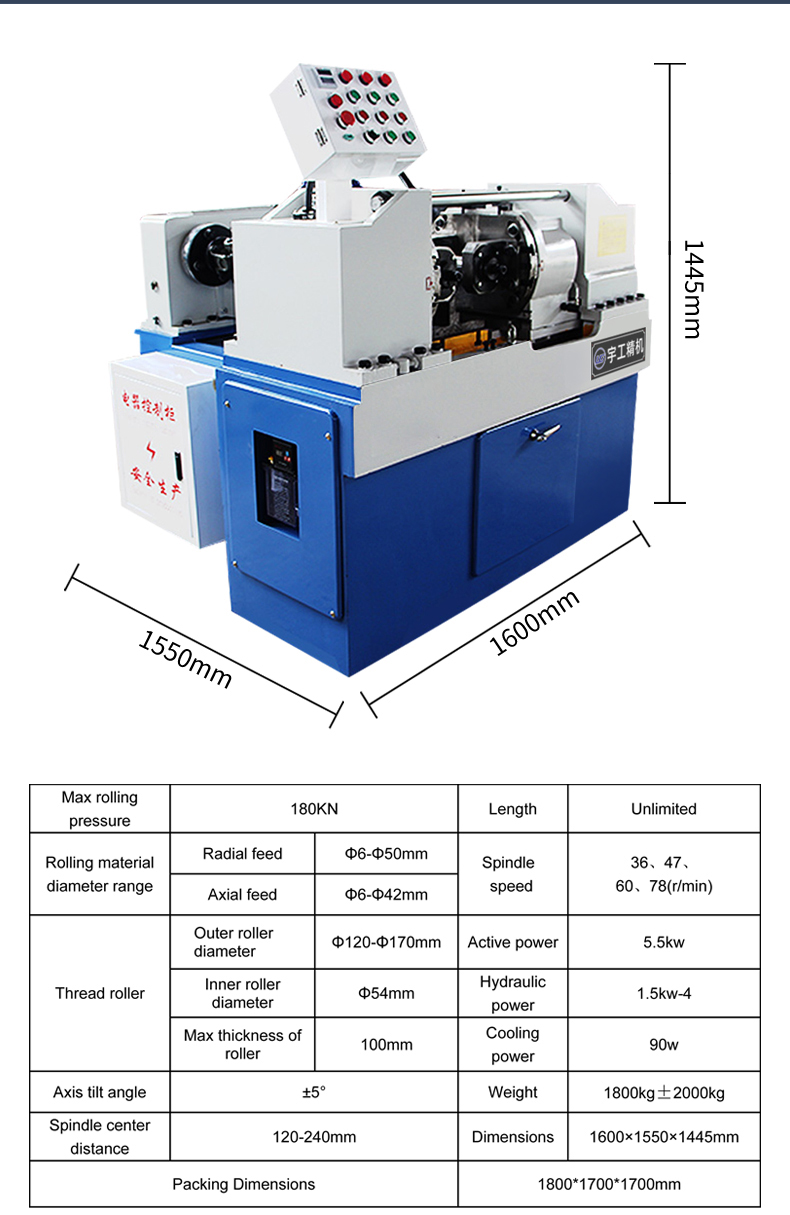

mini thread rolling machine

The Mini Thread Rolling Machine A Revolution in Precision Engineering

From a professional standpoint, the expertise required to operate a mini thread rolling machine is surprisingly moderate, thanks to its user-friendly interface and intuitive operation protocols. This accessibility has allowed both seasoned professionals and newcomers to quickly adapt and fully exploit the machine's capabilities. The seamless integration of digital controls and automation features means that operators can easily monitor and adjust the process parameters, resulting in reduced downtime and minimal material wastage. Trust in the reliability of mini thread rolling machines is reinforced by their robust construction and the use of high-quality materials that withstand the rigors of continuous operation. Manufacturers often provide comprehensive training and customer support, ensuring that users are well-equipped to handle any technical challenges. This proactive approach is a testament to the commitment these manufacturers have towards maintaining trust and ensuring optimal performance for the end-user. The authoritativeness of mini thread rolling machines is further established through extensive testing and certification processes. Leading industry bodies regularly conduct evaluations to verify the efficiency and safety of these machines, providing users with the assurance that they meet global operational and safety standards. The growing body of literature and case studies published in reputable engineering journals attests to the machine's capabilities and the numerous advantages it brings to various machining operations. In conclusion, the mini thread rolling machine is not just a tool, but a transformative piece of equipment that embodies precision, efficiency, and reliability. Its contribution to the field of precision engineering is invaluable, providing a trustworthy solution that meets the complex demands of modern manufacturing. With ongoing advancements and innovations, it is poised to remain a cornerstone in the production of high-quality components for years to come.

From a professional standpoint, the expertise required to operate a mini thread rolling machine is surprisingly moderate, thanks to its user-friendly interface and intuitive operation protocols. This accessibility has allowed both seasoned professionals and newcomers to quickly adapt and fully exploit the machine's capabilities. The seamless integration of digital controls and automation features means that operators can easily monitor and adjust the process parameters, resulting in reduced downtime and minimal material wastage. Trust in the reliability of mini thread rolling machines is reinforced by their robust construction and the use of high-quality materials that withstand the rigors of continuous operation. Manufacturers often provide comprehensive training and customer support, ensuring that users are well-equipped to handle any technical challenges. This proactive approach is a testament to the commitment these manufacturers have towards maintaining trust and ensuring optimal performance for the end-user. The authoritativeness of mini thread rolling machines is further established through extensive testing and certification processes. Leading industry bodies regularly conduct evaluations to verify the efficiency and safety of these machines, providing users with the assurance that they meet global operational and safety standards. The growing body of literature and case studies published in reputable engineering journals attests to the machine's capabilities and the numerous advantages it brings to various machining operations. In conclusion, the mini thread rolling machine is not just a tool, but a transformative piece of equipment that embodies precision, efficiency, and reliability. Its contribution to the field of precision engineering is invaluable, providing a trustworthy solution that meets the complex demands of modern manufacturing. With ongoing advancements and innovations, it is poised to remain a cornerstone in the production of high-quality components for years to come.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025