-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Mar . 04, 2025 11:04

Back to list

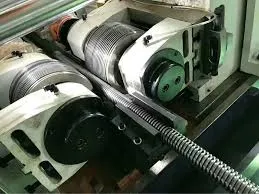

anchor bolt stainless rod thread making machine thread rolling machine

When it comes to mini thread rolling machine factories, one must consider their vital role in modern manufacturing. These specialized factories play a crucial part in producing miniature threaded components that are essential across a myriad of industries, from electronics to automotive, and aerospace to medical devices.

In terms of expert knowledge, factories often have teams of metallurgists and engineers who constantly assess different alloys and materials to push the boundaries of what's possible. This expertise is paramount as industries push towards lighter, more durable materials. As a testament to their Authoritativeness, many factories possess certifications such as ISO 9001, signifying their adherence to the highest standards of quality management. Furthermore, these factories frequently engage in collaborative projects with top universities and research institutions to remain at the forefront of innovation. Trustworthiness in the mini thread rolling industry also derives from decades of operational integrity and customer satisfaction. Many leading factories offer open-door policies for audits and factory tours, showcasing transparency in their processes. Client testimonials and long-term partnerships with leading brands attest to their reliability. From a product perspective, the mini thread rolling machines themselves represent pinnacle engineering achievements. Designed to handle a variety of materials, these machines are equipped with features that reduce setup times, improve cycle efficiency, and allow for rapid tool changes. Maintenance protocols for these machines are stringent, often involving regular upkeep schedules and using only industry-grade lubricants and components to maximize performance and lifespan. In evaluating the impact of mini thread rolling machine factories, one can’t overlook the economic and environmental efficiencies they offer. By minimizing waste, reducing energy consumption, and employing sustainable practices, these factories not only contribute positively to the environment but also help reduce costs for their clients. In summation, mini thread rolling machine factories are the silent but profound powerhouses driving numerous industries forward. Their commitment to quality, technological advancement, and customer satisfaction ensures that they stay ahead in the competitive landscape. Explore these factories, and you’ll find a world where precision meets innovation, and where the macroscopic benefits of microscopic attention to detail shine through.

In terms of expert knowledge, factories often have teams of metallurgists and engineers who constantly assess different alloys and materials to push the boundaries of what's possible. This expertise is paramount as industries push towards lighter, more durable materials. As a testament to their Authoritativeness, many factories possess certifications such as ISO 9001, signifying their adherence to the highest standards of quality management. Furthermore, these factories frequently engage in collaborative projects with top universities and research institutions to remain at the forefront of innovation. Trustworthiness in the mini thread rolling industry also derives from decades of operational integrity and customer satisfaction. Many leading factories offer open-door policies for audits and factory tours, showcasing transparency in their processes. Client testimonials and long-term partnerships with leading brands attest to their reliability. From a product perspective, the mini thread rolling machines themselves represent pinnacle engineering achievements. Designed to handle a variety of materials, these machines are equipped with features that reduce setup times, improve cycle efficiency, and allow for rapid tool changes. Maintenance protocols for these machines are stringent, often involving regular upkeep schedules and using only industry-grade lubricants and components to maximize performance and lifespan. In evaluating the impact of mini thread rolling machine factories, one can’t overlook the economic and environmental efficiencies they offer. By minimizing waste, reducing energy consumption, and employing sustainable practices, these factories not only contribute positively to the environment but also help reduce costs for their clients. In summation, mini thread rolling machine factories are the silent but profound powerhouses driving numerous industries forward. Their commitment to quality, technological advancement, and customer satisfaction ensures that they stay ahead in the competitive landscape. Explore these factories, and you’ll find a world where precision meets innovation, and where the macroscopic benefits of microscopic attention to detail shine through.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025