-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

nail thread rolling machine

Understanding Nail Thread Rolling Machines An Essential Tool in Fastener Manufacturing

In today's fast-paced manufacturing environment, the demand for precision and efficiency has never been higher. Among the critical aspects of the manufacturing process, the production of high-quality fasteners, particularly nails, stands out. To meet these demands, manufacturers rely on advanced machinery, with the nail thread rolling machine playing a pivotal role.

What is a Nail Thread Rolling Machine?

A nail thread rolling machine is specialized equipment designed to create threads on nail surfaces. Rather than cutting threads, which can weaken the material, thread rolling uses a cold forming process. This technique involves pressing the metal between two dies to create precise threads without removing any material. The result is a stronger, more durable product that is essential for various applications, from construction and furniture assembly to automotive manufacturing.

Advantages of Using Nail Thread Rolling Machines

1. Increased Strength The cold forming process enhances the material's grain structure, resulting in a more robust and resilient product. This strength is crucial, especially in applications where the nails must bear significant loads.

2. Improved Precision Nail thread rolling machines are engineered for accuracy. They can create uniform threads that meet specific standards, which is vital for ensuring compatibility with other components.

3. Cost Efficiency By eliminating the material removal process associated with thread cutting, thread rolling is often more cost-effective. This advantage allows manufacturers to produce high volumes of nails quickly and at a lower cost.

4. Less Waste The cold forming process generates minimal waste compared to traditional machining methods. This reduction in scrap material is not only environmentally friendly but also enhances overall production efficiency.

nail thread rolling machine

5. Versatility Modern nail thread rolling machines can accommodate various nail sizes and types. This flexibility allows manufacturers to switch between different products with minimal downtime, making it easier to respond to market changes.

The Working Mechanism

The operation of a nail thread rolling machine can be broken down into several key steps. First, a straight metal rod is fed into the machine. The rolling dies are then brought together under high pressure, forcing the metal to flow and form threads. The speed of the operation can be adjusted to optimize production rates, and careful monitoring ensures that each product adheres to quality specifications.

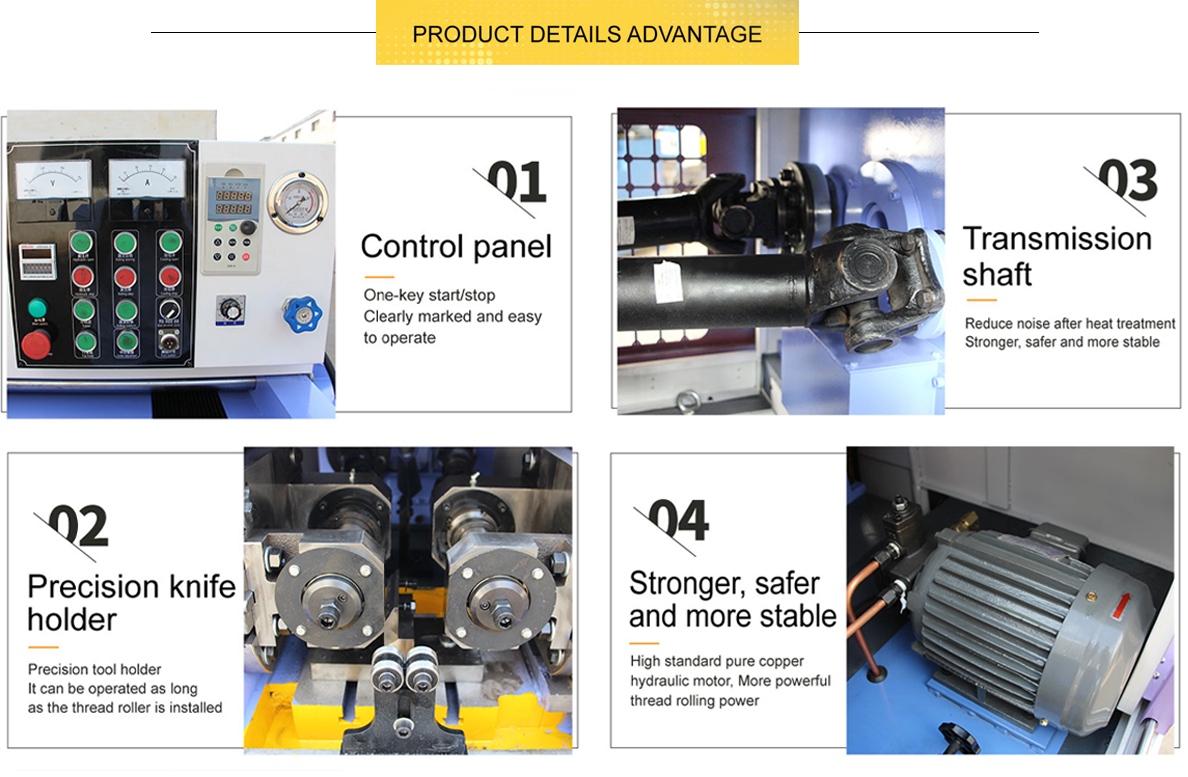

The machine can be configured for different thread profiles and diameters, allowing for the production of various nails tailored to specific applications. Additionally, many machines are equipped with advanced controls that enable operators to fine-tune settings, ensuring consistency across production runs.

Innovations and Future Trends

As technology advances, nail thread rolling machines are becoming increasingly sophisticated. Innovations include automation and robotics, which enhance production efficiency and reduce human error. Integration with data analytics and machine learning is also on the rise, allowing manufacturers to predict maintenance needs and optimize performance in real-time.

Sustainability is another prominent trend, with manufacturers seeking eco-friendly practices in production. As a result, developers are exploring new materials that are not only stronger but also more sustainable.

Conclusion

In conclusion, the nail thread rolling machine is an integral element of the fastener manufacturing industry. Its ability to produce high-strength, precise, and cost-effective nails makes it an invaluable asset. As technology continues to evolve, these machines will likely play an even more significant role in meeting the demands of modern manufacturing, embodying innovation while remaining committed to sustainability. Understanding and investing in these machines is essential for manufacturers aiming to stay competitive in a rapidly changing market.