-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 16, 2025 15:22

Back to list

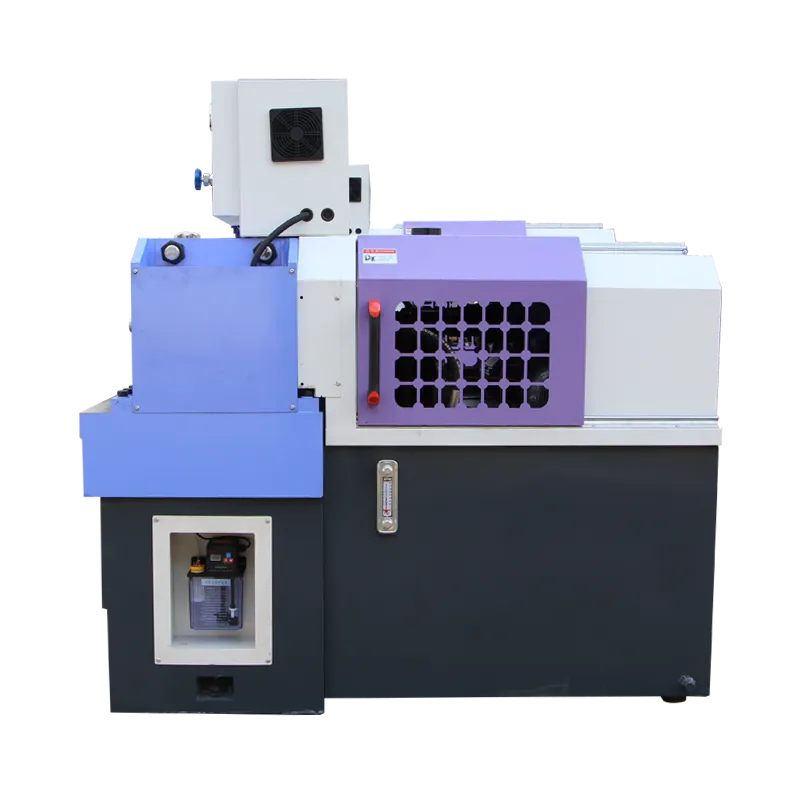

nail thread rolling machine products

In the bustling world of manufacturing, nail thread rolling machines have emerged as a game-changer for businesses seeking efficiency, precision, and durability. These machines have transformed the production of threaded nails, providing solutions to meet the ever-increasing demands of industries such as construction, carpentry, and industrial manufacturing. With a focus on enhancing the production process, nail thread rolling machines embody the perfect balance between advanced engineering and practical functionality.

While efficiency and customization are at the forefront of their design, safety is another pivotal aspect that solidifies their reputation. Equipped with advanced safety mechanisms, these machines minimize operator risk, reinforcing their trustworthiness in an industrial setting. Emergency stops, protective covers, and automated shut-off systems ensure a safe working environment, reflecting the commitment to operator safety without sacrificing performance. Furthermore, the environmental impact is significantly minimized with nail thread rolling machines. The cold-forming process produces less waste compared to traditional methods, aligning with global sustainability goals. This eco-friendly attribute not only enhances the machine’s appeal among environmentally-conscious businesses but also demonstrates an understanding of contemporary industrial challenges. Feedback from industry veterans reveals a consistent pattern of satisfaction with the performance of nail thread rolling machines. This reinforces their authoritative position in the market. Businesses that have integrated these machines into their production lines report an increase in both productivity and product quality, showcasing the machine's capability to deliver on its promises. Investing in nail thread rolling machines is not merely about acquiring new equipment; it's about embracing a technology that embodies years of engineering innovation and industrial expertise. These machines are more than just tools; they are comprehensive solutions designed to meet the complex needs of modern manufacturing. Their widespread adoption across various sectors is a testament to their unmatched value and the enduring trust they inspire in users. In conclusion, nail thread rolling machines represent a pinnacle of industrial innovation, marked by their precision, durability, and operational excellence. They stand as a beacon of reliability and trust, poised to drive the next generation of manufacturing advancements. With their eco-friendly benefits, safety features, and proven efficiency, these machines are an indispensable asset for manufacturers committed to excellence and sustainability. Businesses seeking to elevate their production capabilities will find in them not only a machine but a partner in achieving industrial success.

While efficiency and customization are at the forefront of their design, safety is another pivotal aspect that solidifies their reputation. Equipped with advanced safety mechanisms, these machines minimize operator risk, reinforcing their trustworthiness in an industrial setting. Emergency stops, protective covers, and automated shut-off systems ensure a safe working environment, reflecting the commitment to operator safety without sacrificing performance. Furthermore, the environmental impact is significantly minimized with nail thread rolling machines. The cold-forming process produces less waste compared to traditional methods, aligning with global sustainability goals. This eco-friendly attribute not only enhances the machine’s appeal among environmentally-conscious businesses but also demonstrates an understanding of contemporary industrial challenges. Feedback from industry veterans reveals a consistent pattern of satisfaction with the performance of nail thread rolling machines. This reinforces their authoritative position in the market. Businesses that have integrated these machines into their production lines report an increase in both productivity and product quality, showcasing the machine's capability to deliver on its promises. Investing in nail thread rolling machines is not merely about acquiring new equipment; it's about embracing a technology that embodies years of engineering innovation and industrial expertise. These machines are more than just tools; they are comprehensive solutions designed to meet the complex needs of modern manufacturing. Their widespread adoption across various sectors is a testament to their unmatched value and the enduring trust they inspire in users. In conclusion, nail thread rolling machines represent a pinnacle of industrial innovation, marked by their precision, durability, and operational excellence. They stand as a beacon of reliability and trust, poised to drive the next generation of manufacturing advancements. With their eco-friendly benefits, safety features, and proven efficiency, these machines are an indispensable asset for manufacturers committed to excellence and sustainability. Businesses seeking to elevate their production capabilities will find in them not only a machine but a partner in achieving industrial success.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025