-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 17, 2025 10:52

Back to list

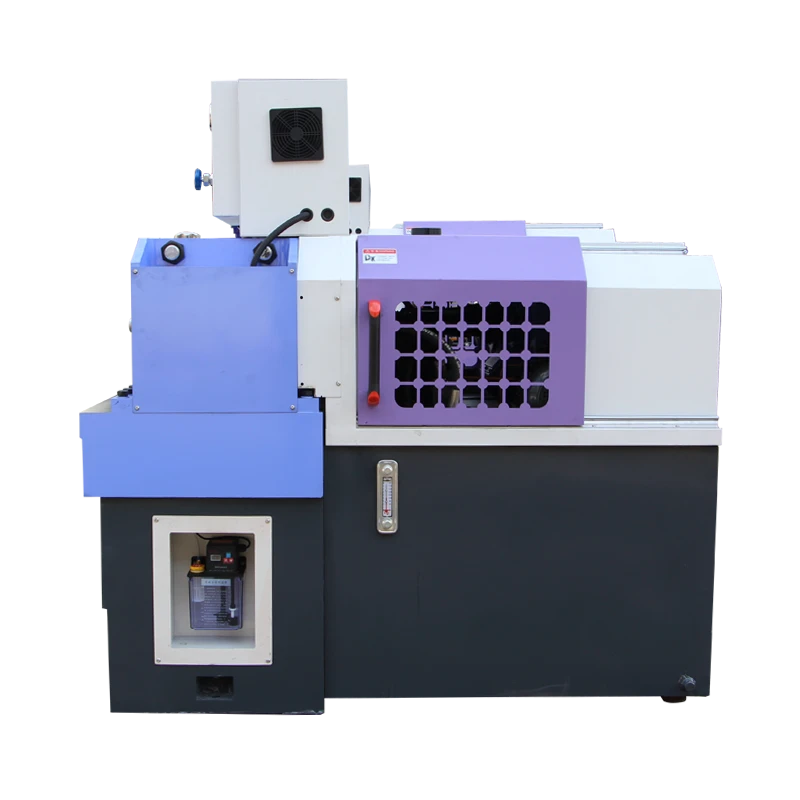

flat die thread rolling machine

Finding the right nail thread rolling machine can be a complex task, especially when considering the specificity and precision required in manufacturing industries. A nail thread rolling machine is pivotal for ensuring the durability and efficiency of nails used in various construction and industrial applications. It is an investment that demands careful evaluation of several critical factors to ensure you are getting a solution that aligns with your specific needs.

The manufacturer’s reputation and after-sales service play a crucial role in this context. Partnering with manufacturers that have a track record of quality and reliability ensures you are investing in proven technology. Support and service agreements that include regular maintenance, prompt customer service, and readily available spare parts contribute to the machine’s efficient operation and reduce potential disruptions. In terms of innovation, it’s beneficial to consider manufacturers that are at the forefront of technology. Machines that incorporate the latest advancements, such as energy efficiency optimizations or connectivity for Industry 4.0 integrations, position your production capabilities ahead of the competition. These cutting-edge technologies not only improve operational efficiency but also future-proof your investment in the rapidly evolving industrial landscape. From a sustainability perspective, it is wise to examine the environmental impact of the machine. Energy-efficient machines contribute to reducing the carbon footprint of your production process. Additionally, manufacturers that follow sustainable manufacturing practices in their production processes further support eco-friendly initiatives, aligning with global environmental standards and potentially offering additional corporate benefits. Ultimately, securing quotes for a nail thread rolling machine involves a comprehensive evaluation of the above factors, geared towards aligning the machine’s features with your operational needs. Engaging with a knowledgeable supplier who can offer guidance and tailored solutions helps ensure that the machine not only meets but exceeds your specific production requirements. Satisfying these criteria ultimately results in enhanced product quality, operational efficiency, and a significant return on investment. As you advance in this pursuit, consider collaborating closely with machine experts who comprehend the intricacies of nail production. Their expertise in machine selection and optimization is invaluable, providing insights that lead to informed decision-making. By integrating these seasoned perspectives, companies can harness the full potential of nail thread rolling technology to foster growth and ensure long-term success in an competitive industry.

The manufacturer’s reputation and after-sales service play a crucial role in this context. Partnering with manufacturers that have a track record of quality and reliability ensures you are investing in proven technology. Support and service agreements that include regular maintenance, prompt customer service, and readily available spare parts contribute to the machine’s efficient operation and reduce potential disruptions. In terms of innovation, it’s beneficial to consider manufacturers that are at the forefront of technology. Machines that incorporate the latest advancements, such as energy efficiency optimizations or connectivity for Industry 4.0 integrations, position your production capabilities ahead of the competition. These cutting-edge technologies not only improve operational efficiency but also future-proof your investment in the rapidly evolving industrial landscape. From a sustainability perspective, it is wise to examine the environmental impact of the machine. Energy-efficient machines contribute to reducing the carbon footprint of your production process. Additionally, manufacturers that follow sustainable manufacturing practices in their production processes further support eco-friendly initiatives, aligning with global environmental standards and potentially offering additional corporate benefits. Ultimately, securing quotes for a nail thread rolling machine involves a comprehensive evaluation of the above factors, geared towards aligning the machine’s features with your operational needs. Engaging with a knowledgeable supplier who can offer guidance and tailored solutions helps ensure that the machine not only meets but exceeds your specific production requirements. Satisfying these criteria ultimately results in enhanced product quality, operational efficiency, and a significant return on investment. As you advance in this pursuit, consider collaborating closely with machine experts who comprehend the intricacies of nail production. Their expertise in machine selection and optimization is invaluable, providing insights that lead to informed decision-making. By integrating these seasoned perspectives, companies can harness the full potential of nail thread rolling technology to foster growth and ensure long-term success in an competitive industry.

Share:

Next:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025