-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

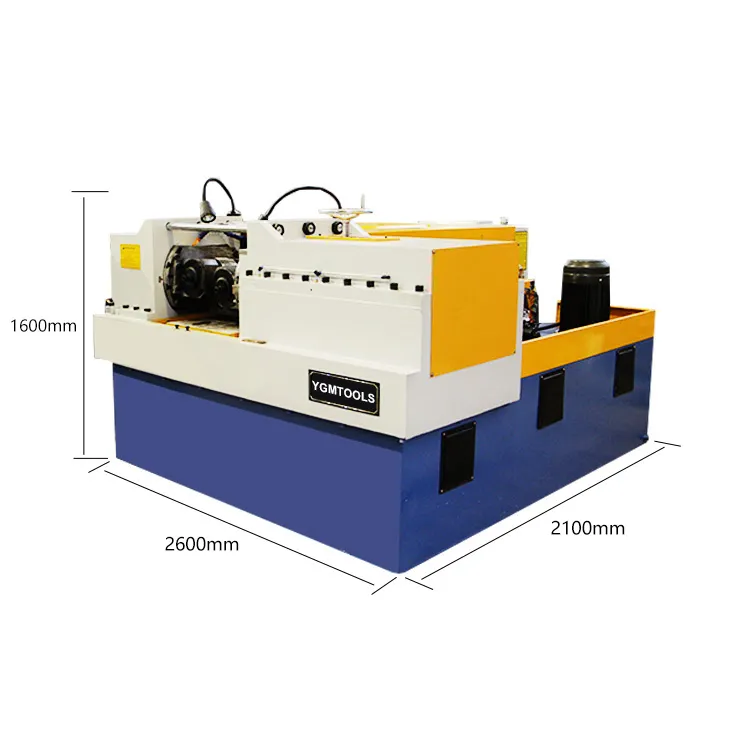

odm rod thread rolling machine

Understanding ODM Rod Thread Rolling Machines A Comprehensive Overview

In the realm of manufacturing and metalworking, the demand for precision and efficiency is ever-increasing. One of the key technologies that have risen to prominence in this sector is the ODM rod thread rolling machine. This specialized equipment has revolutionized the way threaded components are produced, enabling higher accuracy and productivity. In this article, we will explore the fundamental aspects of ODM rod thread rolling machines, their working principles, advantages, applications, and future trends.

What is an ODM Rod Thread Rolling Machine?

An ODM rod thread rolling machine is a sophisticated piece of equipment used to create threads on metal rods using a cold forming process. Unlike traditional machining methods that involve cutting or grinding, thread rolling is a non-cutting process that deforms the material to produce threads. This method not only enhances the strength of the threads but also improves surface finish, making it a preferred choice for many manufacturing applications.

Working Principles

The primary operation of an ODM rod thread rolling machine involves three main components the rolling dies, the rod material, and the hydraulic or mechanical system that drives the motion. The process begins when a cylindrical rod is fed into the machine. The rolling dies, which are precisely shaped to match the desired thread profile, come together and exert immense pressure on the rod as it passes through. This pressure causes the material to flow outward and upward, forming a perfect thread.

The operation is typically carried out at room temperature, which is why it is classified as a cold forming process. The lack of heat not only preserves the material's structural integrity but also results in minimal material wastage, thus making it a cost-effective solution for producing threaded components.

Advantages of ODM Rod Thread Rolling Machines

1. Precision and Accuracy One of the standout features of thread rolling machines is their ability to produce highly precise thread sizes and shapes. The uniformity achieved in mass production is difficult to replicate with traditional machining processes.

2. Increased Strength The cold rolling process enhances the mechanical properties of the material, resulting in threads that are stronger and more durable. This is particularly crucial for applications that require high load-bearing capabilities.

odm rod thread rolling machine

3. Cost-Effectiveness With reduced material waste and faster production speeds, ODM rod thread rolling machines lead to significant cost savings. They are ideal for high-volume production runs where efficiency is paramount.

4. Improved Surface Finish The thread rolling process yields a smoother surface finish compared to cutting methods, reducing the need for secondary finishing processes.

5. Flexibility These machines can be easily adjusted to accommodate various sizes and types of rods, making them versatile tools in the manufacturing sector.

Applications

ODM rod thread rolling machines find applications across a wide range of industries, including automotive, aerospace, construction, and electronics. Common products manufactured using these machines include bolts, screws, spindle rods, and other fasteners that require high precision and strength. Their ability to produce custom thread profiles also makes them suitable for niche applications where standard threading may not suffice.

Future Trends

The future of ODM rod thread rolling machines looks promising, driven by advancements in technology and increasing market demands. Automation and integration with Industry 4.0 principles are set to enhance the efficiency and productivity of thread rolling processes. With innovations such as predictive maintenance, machine learning algorithms, and real-time monitoring systems, manufacturers can expect improved operational reliability and decreased downtime.

Additionally, the growing emphasis on sustainable manufacturing practices is likely to influence the design and operation of these machines. Manufacturers are expected to invest in energy-efficient models that minimize environmental impact while maintaining high production standards.

Conclusion

ODM rod thread rolling machines represent a significant advancement in the field of precision manufacturing. With their ability to produce high-quality, durable threaded components efficiently, they are indispensable in various industries. As technology continues to evolve, we can anticipate even more innovations in thread rolling processes, making them faster, smarter, and more sustainable. For companies looking to enhance their manufacturing capabilities, investing in ODM rod thread rolling machines is a strategic move that promises substantial returns in both productivity and product quality.