-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 04, 2025 03:05

Back to list

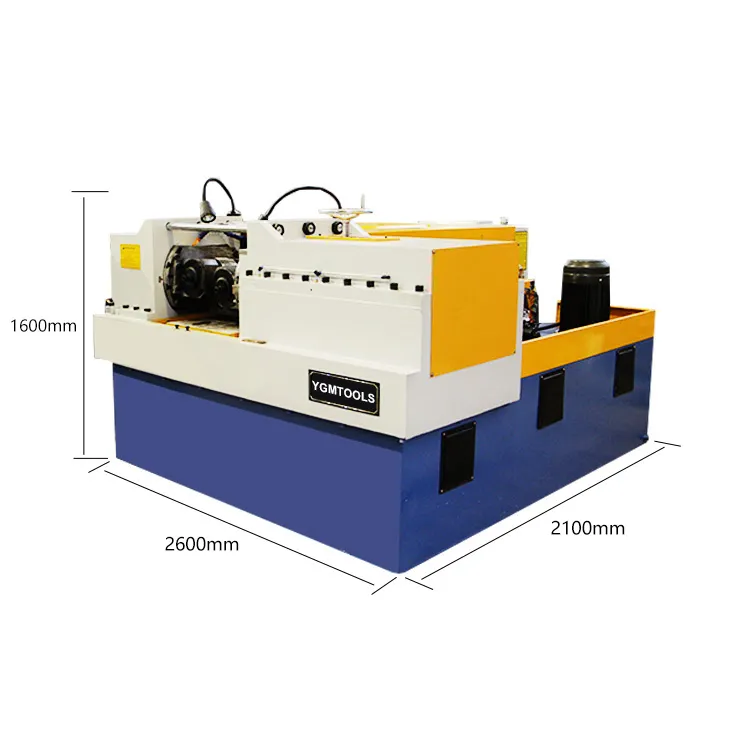

odm thread rolling machine for sale

Finding the perfect ODM thread rolling machine for sale can be a game-changer for manufacturing businesses seeking to enhance their production capabilities. Thread rolling, an essential process in manufacturing, creates threads on components by cold forming rather than cutting, which results in stronger and more precise threads. The selection of a reputable Original Design Manufacturer (ODM) for a thread rolling machine that fits your manufacturing needs can significantly impact your production efficiency and product quality.

When building a trustworthy relationship with an ODM manufacturer, thorough research is indispensable. Start by exploring customer reviews and case studies to gather insights on how these machines perform in real-world scenarios. In my experience, an ODM that is open about its manufacturing process and provides extensive documentation, as well as post-sale support, typically earns a higher trust index among its clientele. As with any major purchase in the manufacturing domain, cost versus benefit analysis cannot be overstated. Investing in an ODM thread rolling machine may initially appear more expensive compared to off-the-shelf alternatives; however, the long-term benefits often outweigh the upfront costs. Enhanced efficiency, better thread quality, and increased customization options contribute significantly to ROI. Moreover, the global shift towards Industry 4.0 emphasizes the importance of integrating smart technologies in manufacturing processes. Top ODMs are at the forefront of integrating IoT and automation into thread rolling machines, offering remote monitoring, predictive maintenance, and even AI-driven operations. This technological edge not only bolsters production efficiency but also amplifies scalability, allowing businesses to expand operations without significant additional investments. In summary, as a manufacturing veteran, my advice to any business considering the purchase of an ODM thread rolling machine is to prioritize a partner’s experience, commitment to innovation, and service excellence. These components significantly contribute to acquiring a tool that not only meets current production demands but also aligns with future growth objectives. In an ever-evolving market, having a robust, reliable, and technological advanced thread rolling machine can make the difference between merely surviving and thriving in the competitive manufacturing landscape.

When building a trustworthy relationship with an ODM manufacturer, thorough research is indispensable. Start by exploring customer reviews and case studies to gather insights on how these machines perform in real-world scenarios. In my experience, an ODM that is open about its manufacturing process and provides extensive documentation, as well as post-sale support, typically earns a higher trust index among its clientele. As with any major purchase in the manufacturing domain, cost versus benefit analysis cannot be overstated. Investing in an ODM thread rolling machine may initially appear more expensive compared to off-the-shelf alternatives; however, the long-term benefits often outweigh the upfront costs. Enhanced efficiency, better thread quality, and increased customization options contribute significantly to ROI. Moreover, the global shift towards Industry 4.0 emphasizes the importance of integrating smart technologies in manufacturing processes. Top ODMs are at the forefront of integrating IoT and automation into thread rolling machines, offering remote monitoring, predictive maintenance, and even AI-driven operations. This technological edge not only bolsters production efficiency but also amplifies scalability, allowing businesses to expand operations without significant additional investments. In summary, as a manufacturing veteran, my advice to any business considering the purchase of an ODM thread rolling machine is to prioritize a partner’s experience, commitment to innovation, and service excellence. These components significantly contribute to acquiring a tool that not only meets current production demands but also aligns with future growth objectives. In an ever-evolving market, having a robust, reliable, and technological advanced thread rolling machine can make the difference between merely surviving and thriving in the competitive manufacturing landscape.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025