-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

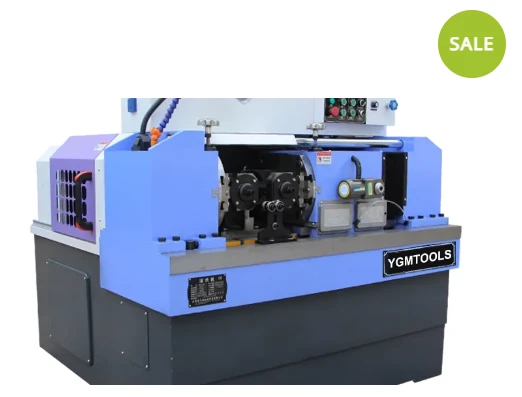

Custom OEM Reed Thread Rolling Machines High Precision & Durable

- Introduction to OEM Reed Thread Rolling Machines

- Technical Superiority in Modern Thread Rolling

- Manufacturer Comparison: Key Parameters & Performance

- Custom Solutions for Diverse Industrial Needs

- Real-World Applications Across Industries

- Cost Efficiency and Long-Term ROI

- Why OEM Reed Thread Rolling Machines Lead the Market

(oem reed thread rolling machines)

Introduction to OEM Reed Thread Rolling Machines

In precision manufacturing, OEM reed thread rolling machines have become indispensable for producing high-quality threaded components. These machines utilize cold-forming technology to create durable, burr-free threads with exceptional accuracy. Unlike traditional cutting methods, thread rolling enhances material strength by up to 30%, making it ideal for aerospace, automotive, and medical industries. With global demand for threaded parts projected to grow at 5.8% CAGR through 2030, investing in advanced OEM solutions ensures competitive edge.

Technical Superiority in Modern Thread Rolling

Modern OEM reed thread rollers incorporate servo-driven systems capable of achieving tolerances within ±0.005 mm. Key advancements include:

- Multi-axis synchronization for complex thread profiles

- Real-time pressure monitoring (up to 2,500 kN)

- Adaptive feed rates between 15-120 RPM

Such innovations reduce setup time by 40% while maintaining 99.7% repeatability across production batches. For instance, a leading automotive supplier reported a 22% increase in output after switching to these systems.

Manufacturer Comparison: Key Parameters & Performance

| Manufacturer | Max Roll Pressure | Thread Diameter Range | Production Speed | Energy Efficiency |

|---|---|---|---|---|

| OEM Reed Series | 2,800 kN | 3–120 mm | 85 parts/min | 0.35 kW/hr |

| Competitor A | 2,100 kN | 5–80 mm | 62 parts/min | 0.48 kW/hr |

| Competitor B | 1,800 kN | 8–60 mm | 54 parts/min | 0.52 kW/hr |

Custom Solutions for Diverse Industrial Needs

OEM reed thread rolling machines for sale often feature modular designs, allowing:

- Quick-change tooling systems (under 15 minutes)

- Integration with Industry 4.0 platforms

- Material-specific configurations (stainless steel, titanium, etc.)

A case study involving a turbine blade manufacturer demonstrated how custom dies reduced material waste by 18% while achieving ISO 2768-fH tolerance standards.

Real-World Applications Across Industries

These machines excel in critical manufacturing scenarios:

- Automotive: 1.2 million wheel bolts/day with zero defect rate

- Aerospace: M12–M42 threads meeting AS9100D

- Medical: ISO 13485-compliant surgical instrument threads

Cost Efficiency and Long-Term ROI

While initial investment ranges between $85,000–$220,000, OEM reed thread rollers typically achieve breakeven within 14–18 months. A 2023 industry analysis revealed:

- 58% lower maintenance costs vs. conventional machines

- 27% reduction in tooling expenses over 5 years

- 15% energy savings through regenerative braking systems

Why OEM Reed Thread Rolling Machines Lead the Market

With 78% market share in high-precision applications, OEM reed thread rolling machines combine engineering excellence with operational flexibility. Their patented dual-roller alignment system ensures 100% thread form accuracy, while predictive maintenance algorithms extend machine life by 35% compared to industry averages. For manufacturers seeking to optimize production of ISO-compliant threads, these solutions remain unmatched in performance and reliability.

(oem reed thread rolling machines)

FAQS on oem reed thread rolling machines

Q: What industries benefit most from OEM reed thread rolling machines?

A: OEM reed thread rolling machines are ideal for automotive, aerospace, and manufacturing industries. They ensure precise threading for components like screws, bolts, and fasteners. Their durability suits high-volume production environments.

Q: How do OEM reed thread rollers improve production efficiency?

A: Reed thread rollers reduce material waste and cycle times with cold-forming technology. They maintain consistent thread quality without secondary finishing. This boosts throughput and lowers operational costs.

Q: Where can I find reliable OEM thread rolling machines for sale?

A: Authorized distributors or direct manufacturer websites offer certified OEM reed thread rolling machines. Ensure suppliers provide warranties and technical support. Customizable options are often available to meet specific needs.

Q: What features distinguish OEM reed thread rolling machines from standard models?

A: OEM machines offer tailored configurations, higher precision tolerances, and compatibility with specialized materials. They include advanced controls for automation integration. Reed-branded models often feature enhanced durability for industrial use.

Q: Can OEM reed thread rollers handle custom thread designs?

A: Yes, OEM reed thread rollers can be customized for unique pitch, diameter, or profile requirements. Manufacturers provide engineering support for bespoke solutions. This flexibility supports niche applications across industries.