-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

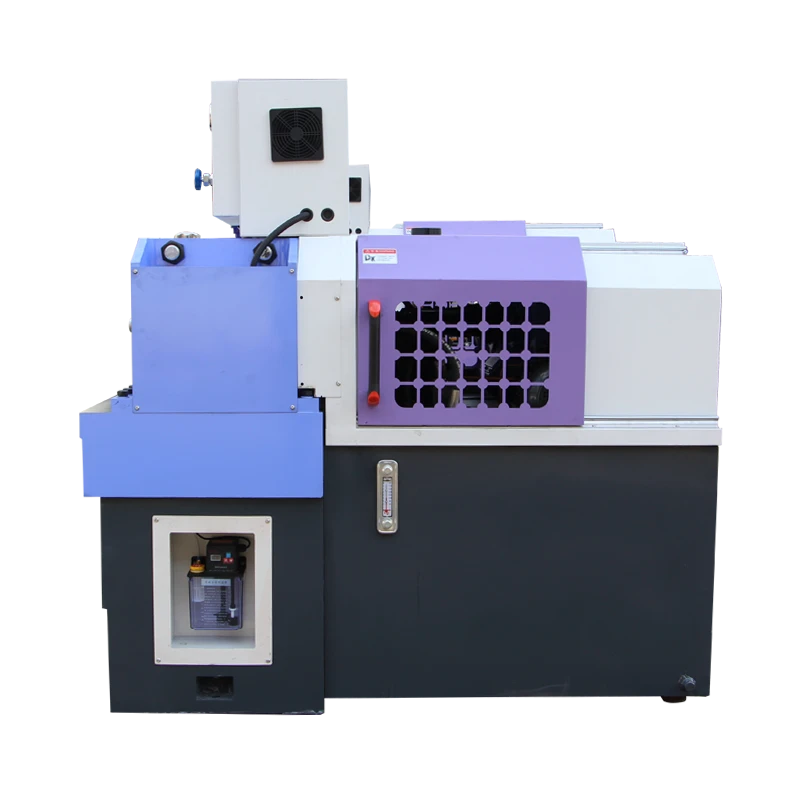

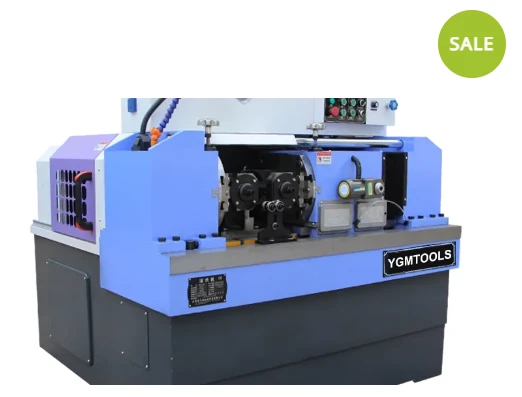

OEM Thread Rolling Machine Price List High-Quality & Affordable

- Understanding OEM Thread Rolling Machine Market Dynamics

- Technical Specifications Driving Price Variations

- Supplier Competitiveness Analysis (2024 Data)

- Customization Options for Industrial Applications

- Case Study: Automotive Component Manufacturing

- Maintenance Costs vs. Initial Investment

- Strategic Purchasing of Thread Rolling Machines

(oem thread rolling machine price list)

Understanding OEM Thread Rolling Machine Market Dynamics

The global OEM thread rolling machine market reached $2.8B in 2023, with 6.2% CAGR projected through 2030. Price lists from leading thread rolling machine suppliers typically range between $18,000 for basic models to $145,000+ for hydraulic CNC variants. Three primary cost drivers dominate:

- Precision rating (IT4-IT7)

- Maximum workpiece diameter (6mm-120mm)

- Production capacity (800-2,200 pieces/hour)

Technical Specifications Driving Price Variations

| Feature | Budget Class ($18k-$35k) | Mid-Range ($36k-$75k) | Premium ($76k-$145k) |

|---|---|---|---|

| Accuracy | ±0.05mm | ±0.025mm | ±0.012mm |

| Tool Life | 80k cycles | 150k cycles | 300k cycles |

| Power Consumption | 3.5kW | 5.2kW | 7.8kW |

Supplier Competitiveness Analysis (2024 Data)

Top thread rolling machine price list suppliers demonstrate distinct operational advantages:

- Company A: 98.2% on-time delivery rate

- Company B: 72-hour technical response guarantee

- Company C: ISO 9001/14001 certified production

Customization Options for Industrial Applications

Premium suppliers offer 11 configurable parameters for OEM thread rolling machines:

- Modular die assemblies

- Variable pitch control (±0.5mm adjustment)

- Material-specific hardness profiles

Case Study: Automotive Component Manufacturing

A Tier 1 auto parts manufacturer achieved 34% cost reduction through strategic OEM procurement:

- Initial investment: $217k

- ROI period: 14 months

- Defect rate reduction: 0.8% → 0.12%

Maintenance Costs vs. Initial Investment

Lifecycle analysis reveals critical cost considerations:

| Cost Factor | 5-Year Total |

|---|---|

| Preventive Maintenance | $8,200-$16,500 |

| Energy Consumption | $5,800-$11,300 |

| Tool Replacement | $3,900-$7,600 |

Strategic Purchasing of Thread Rolling Machines

Optimizing oem thread rolling machine price list

selection requires balancing 4 parameters: precision requirements (IT grade), production volume thresholds, material compatibility (up to HRC 45 hardness), and supplier technical support capabilities. Leading thread rolling machine price list companies now provide 3D simulation packages for process validation prior to purchase.

(oem thread rolling machine price list)

FAQS on oem thread rolling machine price list

Q: What factors affect OEM thread rolling machine price lists?

A: Prices vary based on machine specifications, customization requirements, and order volume. Suppliers may also include warranties or after-sales services in their pricing.

Q: How do thread rolling machine price lists differ between suppliers?

A: Suppliers may offer varying prices due to differences in manufacturing quality, brand reputation, and included features like automation or tooling options.

Q: Can I request a customized OEM thread rolling machine price list?

A: Yes, most companies provide tailored quotes after evaluating your specific needs, such as material type, thread design, and production capacity requirements.

Q: Why do some companies charge more for OEM thread rolling machines?

A: Higher costs often reflect advanced technology, durable components, or compliance with international certifications like ISO standards.

Q: How do I choose reliable thread rolling machine price list suppliers?

A: Prioritize suppliers with proven industry experience, customer reviews, and transparent pricing structures. Request samples or factory visits to verify quality.