-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

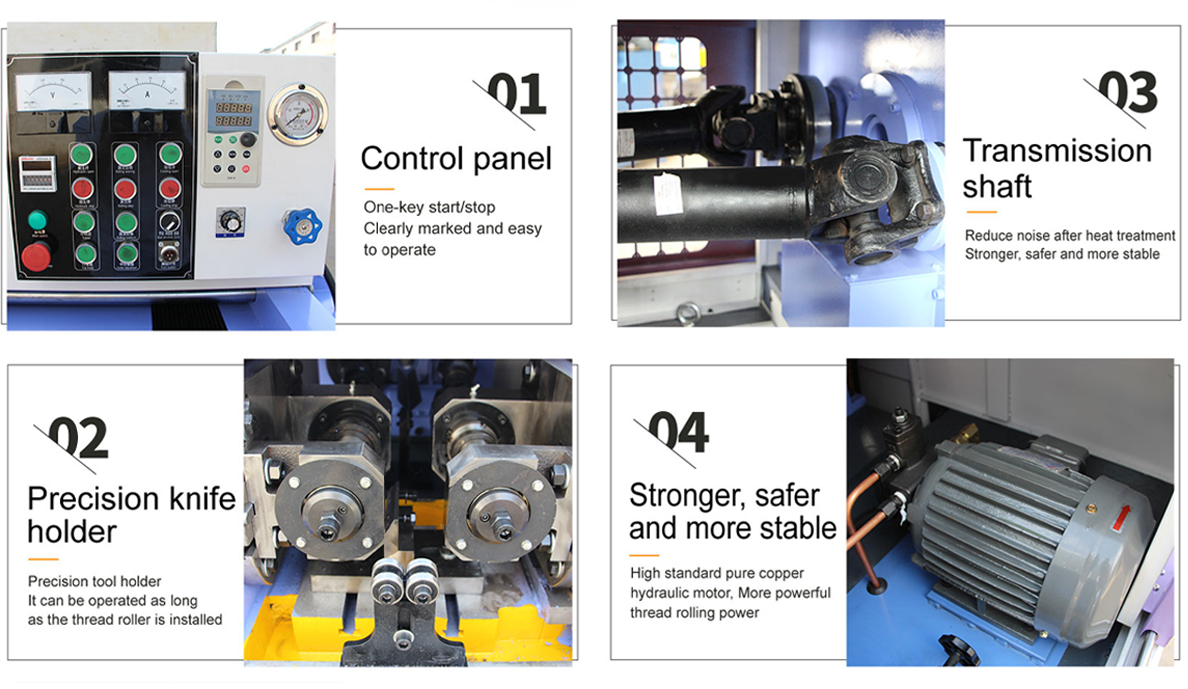

OEM Bolt Rolling Machine for Efficient Fastener Production Solutions

The OEM Bolt Rolling Machine Revolutionizing Fastener Production

In the highly competitive world of manufacturing, efficiency and precision are paramount. One of the crucial machines that play a significant role in the production of fasteners is the OEM bolt rolling machine. This innovative piece of equipment has transformed the way manufacturers produce bolts, offering enhanced speed, accuracy, and cost-effectiveness.

What is an OEM Bolt Rolling Machine?

An OEM (Original Equipment Manufacturer) bolt rolling machine is a specialized piece of machinery designed to shape and form bolts and other fasteners through a cold-forming process. Unlike traditional methods that often involve cutting and machining metal, the bolt rolling technique reshapes material under high pressure, resulting in a product that maintains superior strength and durability.

Advantages of Using a Bolt Rolling Machine

1. Enhanced Material Utilization One of the key benefits of using a bolt rolling machine is its ability to minimize material waste. Cold forming generally requires less material than machining since it involves displacing metal rather than removing it. This advantage not only conserves resources but also contributes to lower production costs.

oem bolt rolling machine

2. Superior Mechanical Properties The cold forming process leads to a denser grain structure in the metal. This improved microstructure grants the finished bolts enhanced mechanical properties, such as increased tensile strength and fatigue resistance. As a result, the bolts produced are often able to withstand greater loads and harsher operating conditions, making them suitable for a wide range of applications.

3. Higher Production Efficiency OEM bolt rolling machines are designed for high-speed production, which significantly reduces the time required to manufacture fasteners. Automated systems allow for quicker changeovers between different sizes and types of bolts, enabling manufacturers to respond swiftly to changing demands.

4. Precision Engineering These machines are engineered to produce bolts with precise dimensions and tolerances. The consistency offered by the bolt rolling process reduces the need for extensive secondary machining operations, improving overall workflow and ensuring high-quality end products.

5. Flexibility Modern OEM bolt rolling machines can handle a variety of materials, including carbon steel, stainless steel, and alloys. They can also produce a diverse range of bolt designs, from standard to custom specifications, making them versatile tools for numerous industries including automotive, aerospace, and construction.

Conclusion

As industries continue to evolve, the demand for high-quality fasteners grows. An OEM bolt rolling machine is a game-changer for manufacturers aiming to enhance their production processes. By combining efficiency, precision, and material savings, these machines not only improve manufacturing outcomes but also contribute to sustainability in production practices. As we look to the future, the importance of advanced machinery like the bolt rolling machine will only increase, solidifying its role as an integral component in the fastener manufacturing landscape. With ongoing technological advancements, the next generation of OEM bolt rolling machines promises even greater capabilities, ensuring that manufacturers can meet the demands of an ever-changing market.