-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

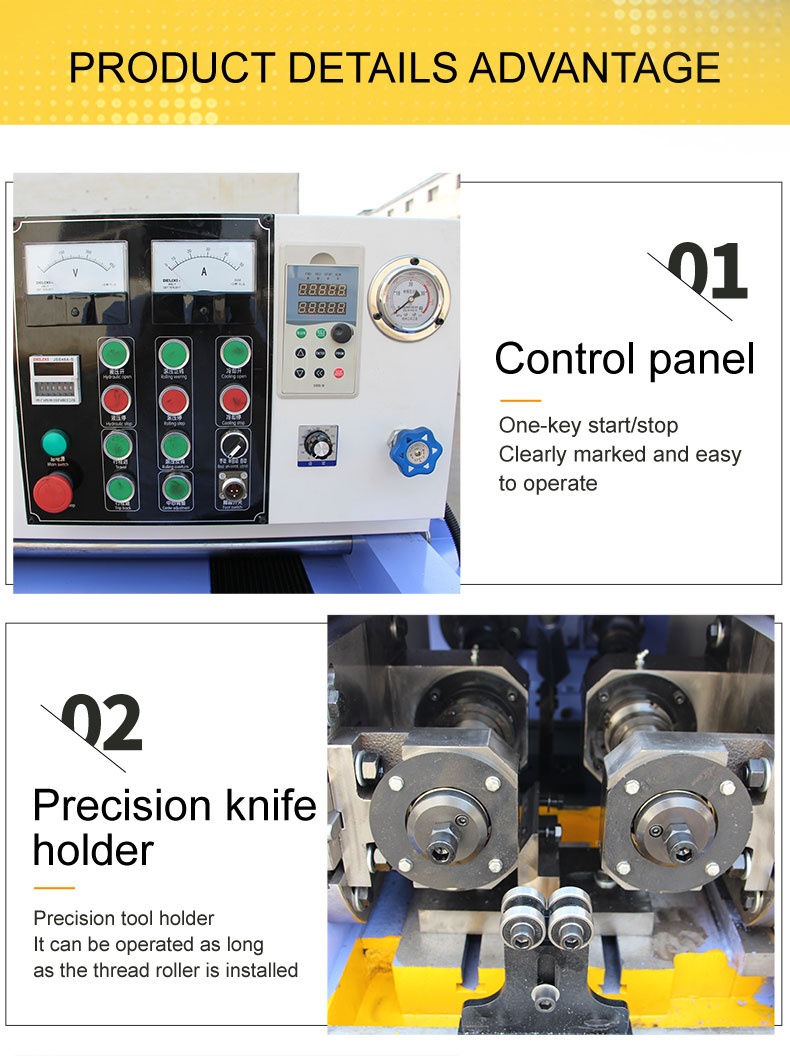

OEM Thread Rolling Machine for Steel Bar Production and Processing

The Importance of OEM Steel Bar Thread Rolling Machines in Modern Manufacturing

In the ever-evolving realm of manufacturing, precision and efficiency are paramount. One of the key players in achieving these ideals is the Original Equipment Manufacturer (OEM) steel bar thread rolling machine. This machine serves as a cornerstone for industries that require high-quality threaded steel bars, which are essential components in construction, automotive, and various engineering applications.

Understanding Thread Rolling Machines

Thread rolling machines are specialized tools designed to produce threads on steel bars through a process called cold working. Unlike traditional methods such as cutting or machining, thread rolling reshapes the material without removing any metal. This technique not only maintains the steel’s intrinsic strength but also enhances the overall durability of the threads. The result is a product that can withstand heavy loads and extreme conditions, making it ideal for critical applications where reliability is a necessity.

Advantages of OEM Steel Bar Thread Rolling Machines

1. Precision and Consistency One of the most significant advantages of OEM thread rolling machines is their ability to produce precise and consistent threads. This consistency is crucial, particularly in applications where threaded components must fit together seamlessly. The precision offered by OEM machines ensures that the specifications are met without deviation, reducing the likelihood of production defects.

2. Increased Production Speed Compared to traditional machining processes, thread rolling is much faster. OEM machines are designed for high efficiency, capable of rolling multiple threads simultaneously. This translates into higher output rates, enabling manufacturers to meet increasing demand without compromising on quality.

3. Material Efficiency The cold working process used in thread rolling results in less material waste. Since no metal is removed during the threading process, more of the initial steel bar is converted into a usable threaded product. This efficiency not only reduces material costs but also supports sustainable manufacturing practices.

oem steel bar thread rolling machine

4. Versatility OEM steel bar thread rolling machines can be configured to produce different thread sizes and types. This versatility allows manufacturers to adapt to various customer demands and industry standards, facilitating a broader array of applications. Whether producing fine threads for precision instruments or heavy-duty threads for construction applications, these machines have the flexibility to meet diverse needs.

5. Enhanced Mechanical Properties The cold working process modifies the microstructure of the metal, often resulting in improved mechanical properties such as tensile strength and fatigue resistance. This enhancement means that products manufactured using OEM thread rolling machines are better equipped to handle stress and strain, leading to longer lifespans and increased safety margins in usage.

Application in the Manufacturing Sector

The use of OEM steel bar thread rolling machines is crucial in several sectors. In construction, for instance, threaded steel bars are used in reinforcement applications, securing structures against various forces. In the automotive industry, these threads are integral to fastening systems, ensuring the structural integrity of vehicles. Furthermore, in machinery manufacturing, threaded components play a vital role in both assembly and functionality, highlighting the universal applicability of thread rolling technology.

Choosing the Right OEM Partner

For manufacturers looking to invest in steel bar thread rolling machines, selecting the right OEM partner is essential. Companies should look for OEMs with a proven track record of innovation, reliability, and customer service. The right partner will not only provide high-quality machines but also offer support in terms of training, maintenance, and technical assistance.

Conclusion

In conclusion, OEM steel bar thread rolling machines represent a crucial advancement in manufacturing technology. Their ability to produce high-strength, precise, and consistent threaded components enables industries to meet modern challenges head-on. As technology continues to advance, the role of these machines will likely expand, solidifying their importance in the manufacturing landscape. Investing in such technology not only satisfies current demand but also positions manufacturers for future success in an increasingly competitive market.