-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

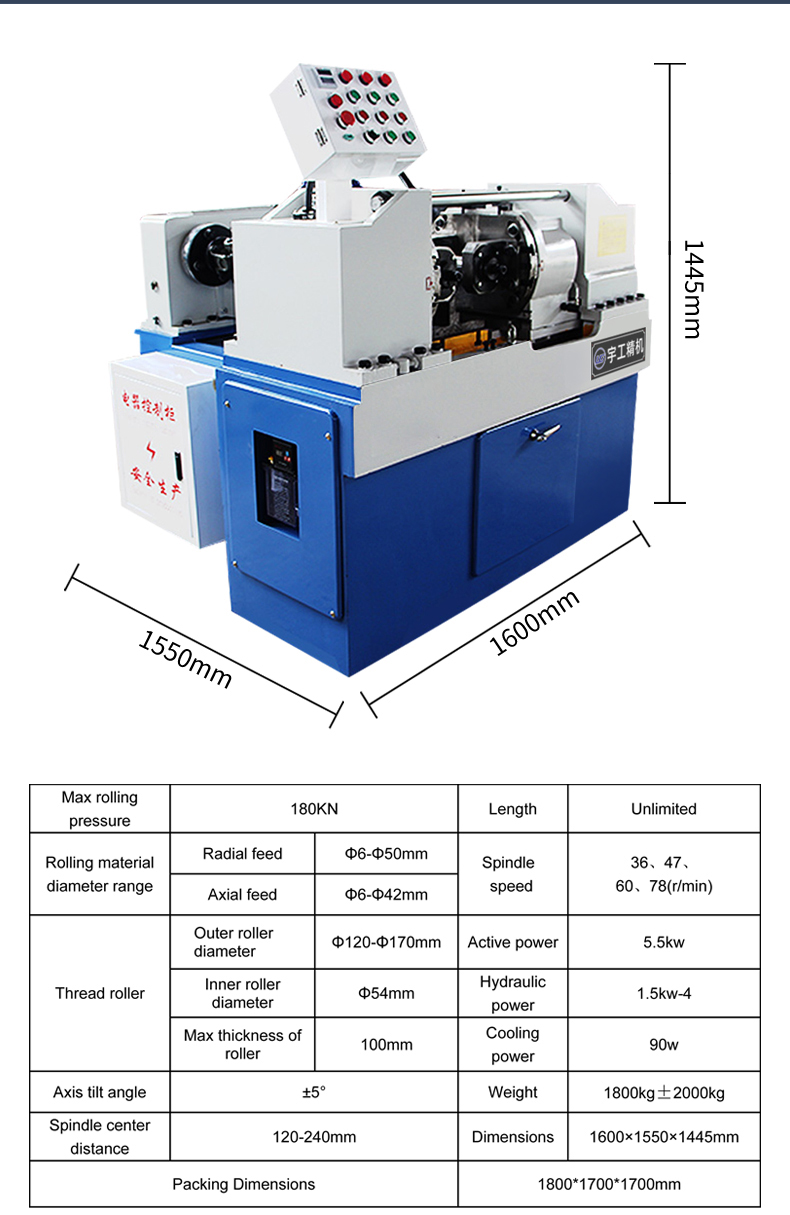

oem thread roller machine

The OEM thread roller machine plays a crucial role in the manufacturing and engineering sectors, particularly in the production of high-quality threaded fasteners. These machines are designed to create threads on various materials through a process known as rotary cold forming, which is known for its efficiency and precision.

.

One of the key advantages of using an OEM thread roller machine is the ability to achieve high production rates without sacrificing quality. The cold forming process leads to a higher strength-to-weight ratio, resulting in stronger, more durable threads compared to traditional cutting methods. Additionally, the absence of chip formation during the rolling process reduces the risk of surface defects, ensuring that the finished product meets stringent industry standards.

oem thread roller machine

Moreover, OEM thread roller machines can be customized to accommodate a variety of thread sizes and shapes, allowing manufacturers to meet specific customer requirements. This versatility is crucial in today's fast-paced market, where the demand for customized solutions is ever-increasing. Manufacturers can choose machines equipped with advanced CNC technology, enabling greater precision and control over the thread-rolling process.

In conclusion, the OEM thread roller machine is an indispensable tool for companies involved in the production of threaded components. Its ability to produce high-quality threads efficiently and with minimal waste makes it an essential investment for manufacturers looking to enhance their productivity and competitiveness. As industries continue to evolve, the role of thread roller machines will undoubtedly expand, paving the way for innovations in manufacturing processes and product quality. Whether you're a small workshop or a large-scale producer, investing in a reliable thread roller machine can significantly improve your operation's overall performance and output.