-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

oem thread rolling equipment

The Importance of OEM Thread Rolling Equipment in Modern Manufacturing

In the fast-paced world of manufacturing, precision and efficiency are paramount. One of the critical processes in producing high-quality mechanical components is thread rolling. This technique, favored for its ability to create strong and durable threads, is increasingly being powered by OEM (Original Equipment Manufacturer) thread rolling equipment. This article delves into the significance of OEM thread rolling equipment in modern manufacturing, its advantages, applications, and future trends in the industry.

Understanding Thread Rolling

Thread rolling is a cold-forming process used to create threads on a variety of materials, usually metal. This process involves the plastic deformation of the material using rolling dies, resulting in threads that are stronger than those produced by traditional cutting methods. The benefits of thread rolling include enhanced strength, reduced material wastage, and superior surface finish. As industries strive for efficiency and quality, the role of thread rolling becomes increasingly critical.

The Role of OEMs in Thread Rolling

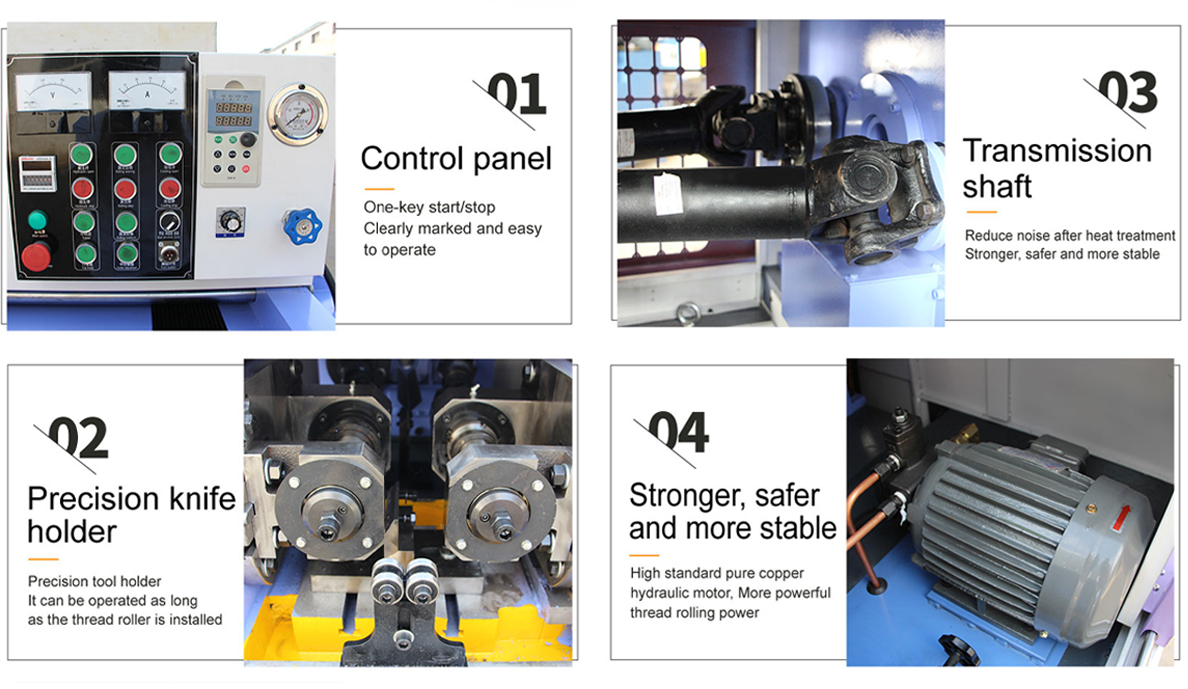

OEMs provide the specialized machinery and technology to facilitate thread rolling. These manufacturers design and produce equipment tailored to specific applications, ensuring that the machinery meets the exact needs of their clients. The precision engineering of OEM thread rolling equipment not only ensures high-quality output but also allows manufacturers to optimize their production processes.

One of the standout features of OEM equipment is its ability to be customized. Customer requirements can vary widely depending on factors such as material type, thread specifications, and production volumes. OEMs can adjust their designs and features to accommodate these variances, providing solutions that are both effective and cost-efficient.

Advantages of OEM Thread Rolling Equipment

1. Quality Assurance OEMs focus on producing high-grade machines that are rigorously tested for quality and durability. This ensures that manufacturers can rely on their equipment for consistent and reliable output.

2. Increased Production Efficiency Advanced features in OEM thread rolling machines, such as automation and enhanced controls, streamline the production process. This results in faster cycle times and ultimately increases throughput.

oem thread rolling equipment

3. Customization As mentioned, OEMs offer customizable solutions. From the size of the machine to the type of rolling dies used, manufacturers can tailor equipment to meet their unique specifications.

4. Support and Maintenance OEMs often provide comprehensive support, including training for operators and maintenance services. This level of support is crucial in minimizing downtime and ensuring that production runs smoothly.

5. Integration with Technology Modern OEM thread rolling equipment often comes equipped with smart technology. This includes features such as real-time monitoring and data analytics, allowing manufacturers to gather valuable insights into their operations.

Applications of Thread Rolling Equipment

The applications of thread rolling equipment are vast and varied. Industries such as automotive, aerospace, and industrial machinery rely heavily on precision threads for components such as bolts, screws, and shafts. The oil and gas sector also utilizes thread rolling for producing parts that must endure extreme conditions. Additionally, the medical device industry has started integrating thread rolling techniques into their manufacturing processes to produce equipment with high precision and reliability.

Future Trends in Thread Rolling Equipment

As manufacturing continues to evolve with technology, so too will thread rolling equipment. There is a growing trend towards automation and the use of artificial intelligence, which will further enhance the efficiency and precision of the rolling processes. Additionally, the push towards sustainability will lead to innovations in reducing waste and energy consumption in thread rolling operations.

Furthermore, as industries explore advanced materials, including composites and high-strength alloys, OEMs will need to adapt their rolling equipment to accommodate these new challenges. This will require ongoing research and development to ensure that manufacturers have access to the latest technology and techniques to stay competitive.

Conclusion

In conclusion, OEM thread rolling equipment plays an essential role in modern manufacturing. With its advantages of quality assurance, efficiency, and customization, this equipment not only meets the current demands of various industries but also paves the way for future advancements. As technology continues to progress, the collaboration between manufacturers and OEMs will be vital in achieving the highest standards of precision and performance in thread rolling applications.