-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

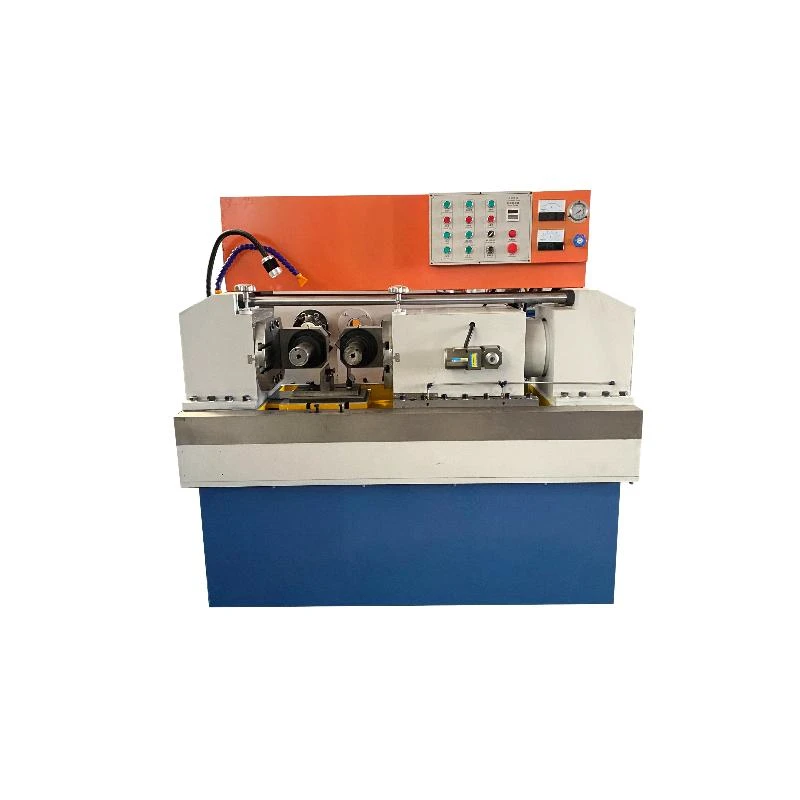

oem thread rolling machine working

Understanding OEM Thread Rolling Machines Functionality and Applications

In the realm of manufacturing and precision engineering, the process of creating threaded fasteners is critical. Among the various methods employed to produce threads, thread rolling has emerged as one of the most efficient and effective techniques. This article explores the functionality of OEM (Original Equipment Manufacturer) thread rolling machines, their working principles, and their applications in various industries.

What is Thread Rolling?

Thread rolling is a cold forming process used to create threads on cylindrical workpieces. Unlike traditional cutting methods that remove material to form threads, thread rolling reshapes the material through the application of pressure, resulting in threads that are stronger and more precise. This process is often used for manufacturing bolts, screws, and other fasteners. The technique not only minimizes waste but also enhances the mechanical properties of the threads, making them ideal for high-stress applications.

The Working Principle of OEM Thread Rolling Machines

OEM thread rolling machines are designed to automate the thread rolling process, increasing efficiency and consistency. Here’s a breakdown of how these machines work

1. Feeding System The process begins with the feeding system, where raw materials, typically in the form of rods or blanks, are fed into the machine. This can be done manually or automatically, depending on the machine's design.

2. Die Selection Once the material is in place, the appropriate rolling dies are selected. These dies are crucial as they determine the thread profile, pitch, and diameter. OEM machines often come equipped with interchangeable dies to accommodate various thread specifications.

3. Thread Rolling Process After die selection, the rolling process commences. The workpiece is positioned between two rotating dies that exert significant pressure on the material. As the dies rotate, they deform the surface of the workpiece, creating the desired thread shape. This process is highly efficient; it can produce multiple threads in a matter of seconds, greatly reducing production times.

4. Cooling System To prevent overheating and ensure material integrity, OEM thread rolling machines include a cooling system. This system circulates coolant around the workpiece and dies, maintaining optimal temperatures during the rolling process.

oem thread rolling machine working

5. Quality Inspection Once the threads are formed, the workpieces are subjected to quality inspection. This may involve measuring thread dimensions and surface finish and checking for defects. Many OEM machines integrate advanced sensors and automated inspection systems to ensure that only high-quality components move to the next production stage.

6. Finishing Processes Depending on the application's requirements, additional finishing processes may follow. These could include heat treatment, plating, or additional machining to achieve specific properties or finishes.

Advantages of OEM Thread Rolling Machines

The use of OEM thread rolling machines offers several advantages

- Increased Production Speed The automated nature of these machines allows for rapid production, significantly reducing lead times. - Enhanced Strength Threads produced through rolling have superior mechanical properties due to the work hardening effect, making them suitable for demanding applications. - Cost-Effective By minimizing material waste and increasing production efficiency, OEM machines can lead to lower overall manufacturing costs. - Precision and Consistency The use of high-quality dies and automated processes ensures that each thread is produced to exact specifications, reducing the likelihood of defects.

Applications Across Industries

OEM thread rolling machines are versatile and find applications in numerous industries

- Automotive Used for manufacturing bolts, screws, and other fasteners for vehicles, where strength and reliability are paramount. - Aerospace Critical for producing fasteners that must withstand extreme conditions. - Construction Essential for creating robust structural components that support various constructions. - Electronics Employed in the production of small screws and fasteners used in electronic devices.

Conclusion

OEM thread rolling machines represent a significant advancement in the technology of fastener manufacturing. Their ability to produce high-quality, strong, and consistent threaded components quickly makes them invaluable in various industries. As manufacturing continues to evolve, these machines will play an increasingly critical role in meeting the demands of modern engineering and production processes.