-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jun . 17, 2024 12:41

Back to list

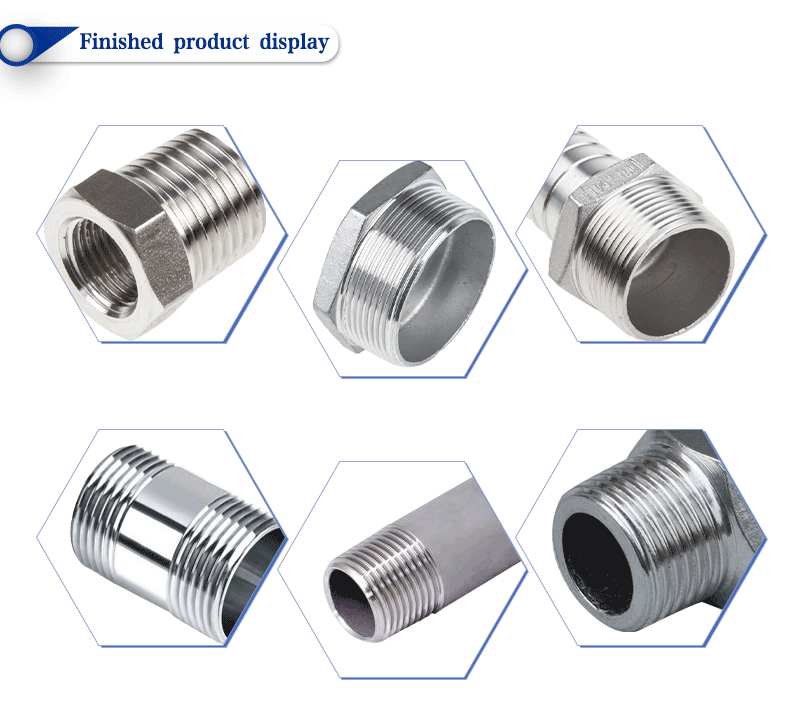

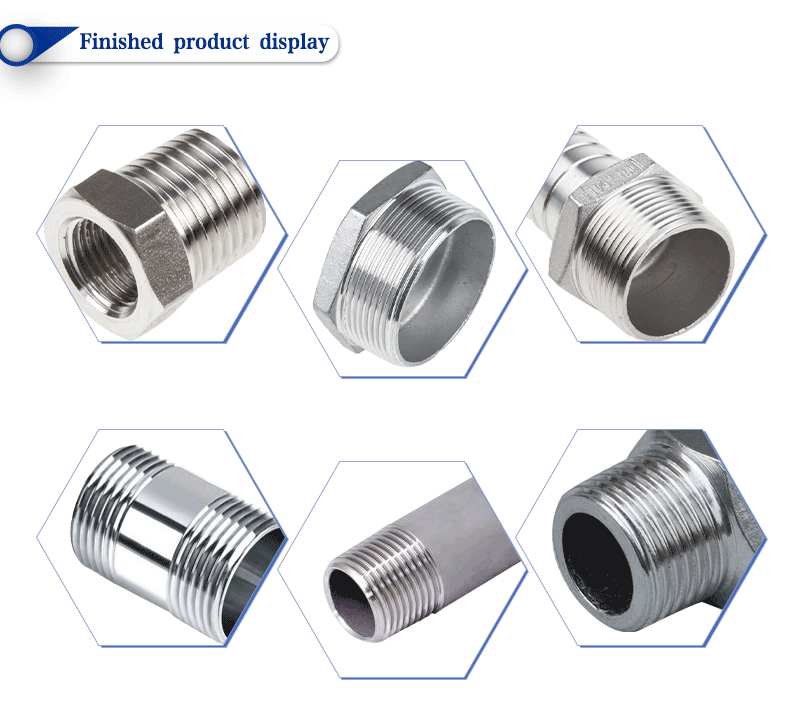

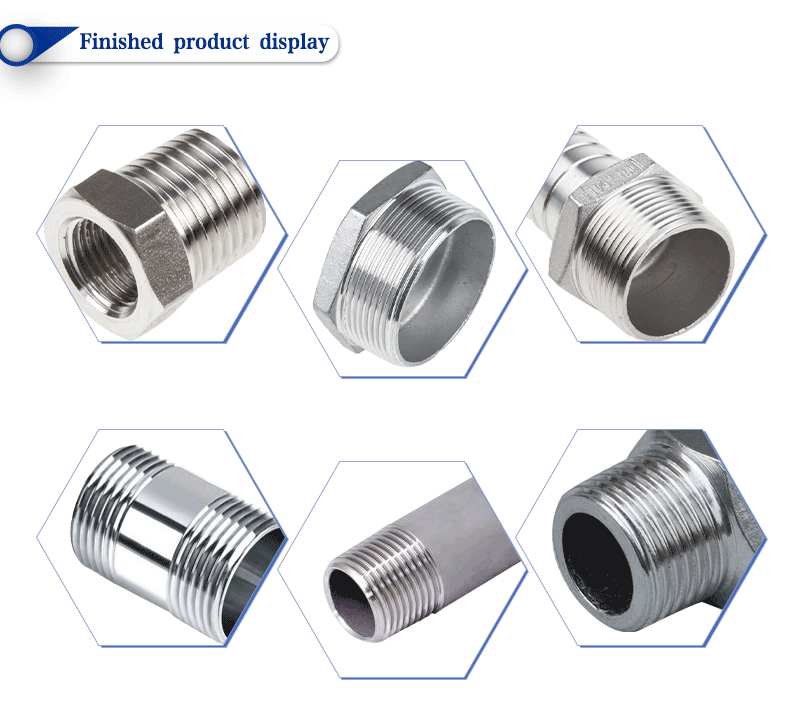

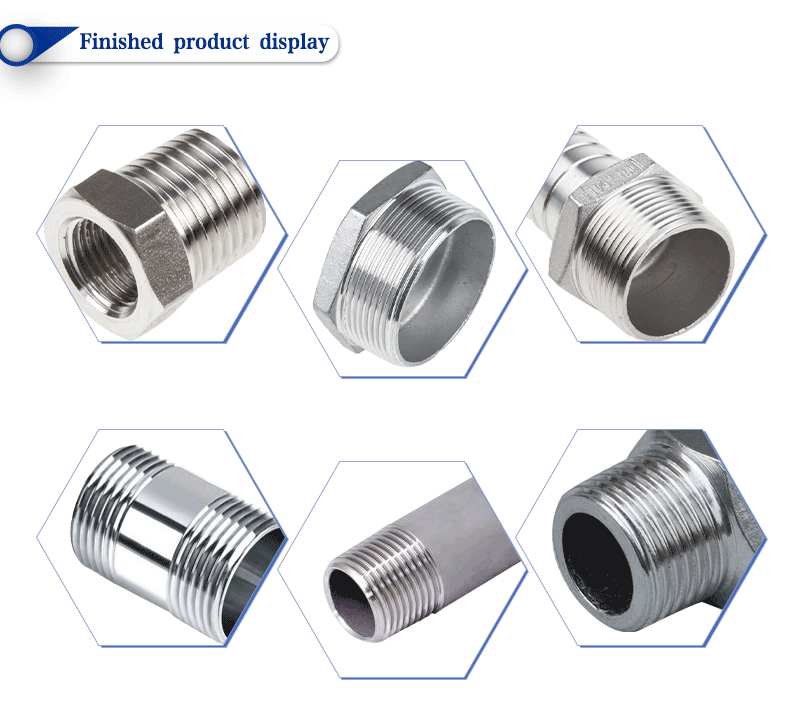

Pipe thread rolling machine products.

The pipe thread rolling machine is an indispensable tool for the modern industrial sector, particularly in the production of pipes and tubes. This innovative piece of machinery employs a unique process that involves the use of dies to form threads on the ends or along the length of pipes. The process is not only efficient but also ensures precision and consistency in the finished product.

At the heart of the pipe thread rolling machine's operation is its rolling mechanism. Unlike cutting or casting methods, rolling forms threads by compressing and deforming the material to create the desired pattern. This method has several advantages. Firstly, it enhances the strength of the connection because the rolled threads are integral to the pipe itself, rather than being a separate piece welded or attached later. Secondly, it reduces material waste as no cutting or removal of metal is involved during the threading process. Lastly, it improves surface finish and accuracy, which is crucial for ensuring a tight seal when the pipes are connected.

The design of a pipe thread rolling machine typically includes a sturdy frame to support the pipe and the rolling dies, a motor to drive the rolling process, and a control system to regulate the depth and pitch of the threads. Some machines may also feature automated feed and positioning systems for increased efficiency and reduced operator involvement Some machines may also feature automated feed and positioning systems for increased efficiency and reduced operator involvement Some machines may also feature automated feed and positioning systems for increased efficiency and reduced operator involvement Some machines may also feature automated feed and positioning systems for increased efficiency and reduced operator involvement

Some machines may also feature automated feed and positioning systems for increased efficiency and reduced operator involvement Some machines may also feature automated feed and positioning systems for increased efficiency and reduced operator involvement pipe thread rolling machine product. These machines can handle a wide range of pipe sizes and materials, from lightweight plastics to heavy-duty metals like steel and copper.

The products resulting from the use of pipe thread rolling machines are varied and essential across numerous industries. In plumbing, these machines facilitate the creation of leak-proof joints for water supply systems. In oil and gas extraction, they ensure secure connections within high-pressure pipelines. Even in construction, rolled threads enable robust and reliable structural supports.

In conclusion, the pipe thread rolling machine represents a significant advancement in manufacturing technology. Its ability to produce precise and strong threaded connections quickly and efficiently makes it a cornerstone of modern industrial processes. As industry continues to evolve, it is likely that these machines will become even more sophisticated, further enhancing their productivity and expanding their applications.

pipe thread rolling machine product. These machines can handle a wide range of pipe sizes and materials, from lightweight plastics to heavy-duty metals like steel and copper.

The products resulting from the use of pipe thread rolling machines are varied and essential across numerous industries. In plumbing, these machines facilitate the creation of leak-proof joints for water supply systems. In oil and gas extraction, they ensure secure connections within high-pressure pipelines. Even in construction, rolled threads enable robust and reliable structural supports.

In conclusion, the pipe thread rolling machine represents a significant advancement in manufacturing technology. Its ability to produce precise and strong threaded connections quickly and efficiently makes it a cornerstone of modern industrial processes. As industry continues to evolve, it is likely that these machines will become even more sophisticated, further enhancing their productivity and expanding their applications.

Some machines may also feature automated feed and positioning systems for increased efficiency and reduced operator involvement Some machines may also feature automated feed and positioning systems for increased efficiency and reduced operator involvement

Some machines may also feature automated feed and positioning systems for increased efficiency and reduced operator involvement Some machines may also feature automated feed and positioning systems for increased efficiency and reduced operator involvement pipe thread rolling machine product. These machines can handle a wide range of pipe sizes and materials, from lightweight plastics to heavy-duty metals like steel and copper.

The products resulting from the use of pipe thread rolling machines are varied and essential across numerous industries. In plumbing, these machines facilitate the creation of leak-proof joints for water supply systems. In oil and gas extraction, they ensure secure connections within high-pressure pipelines. Even in construction, rolled threads enable robust and reliable structural supports.

In conclusion, the pipe thread rolling machine represents a significant advancement in manufacturing technology. Its ability to produce precise and strong threaded connections quickly and efficiently makes it a cornerstone of modern industrial processes. As industry continues to evolve, it is likely that these machines will become even more sophisticated, further enhancing their productivity and expanding their applications.

pipe thread rolling machine product. These machines can handle a wide range of pipe sizes and materials, from lightweight plastics to heavy-duty metals like steel and copper.

The products resulting from the use of pipe thread rolling machines are varied and essential across numerous industries. In plumbing, these machines facilitate the creation of leak-proof joints for water supply systems. In oil and gas extraction, they ensure secure connections within high-pressure pipelines. Even in construction, rolled threads enable robust and reliable structural supports.

In conclusion, the pipe thread rolling machine represents a significant advancement in manufacturing technology. Its ability to produce precise and strong threaded connections quickly and efficiently makes it a cornerstone of modern industrial processes. As industry continues to evolve, it is likely that these machines will become even more sophisticated, further enhancing their productivity and expanding their applications. Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025