-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

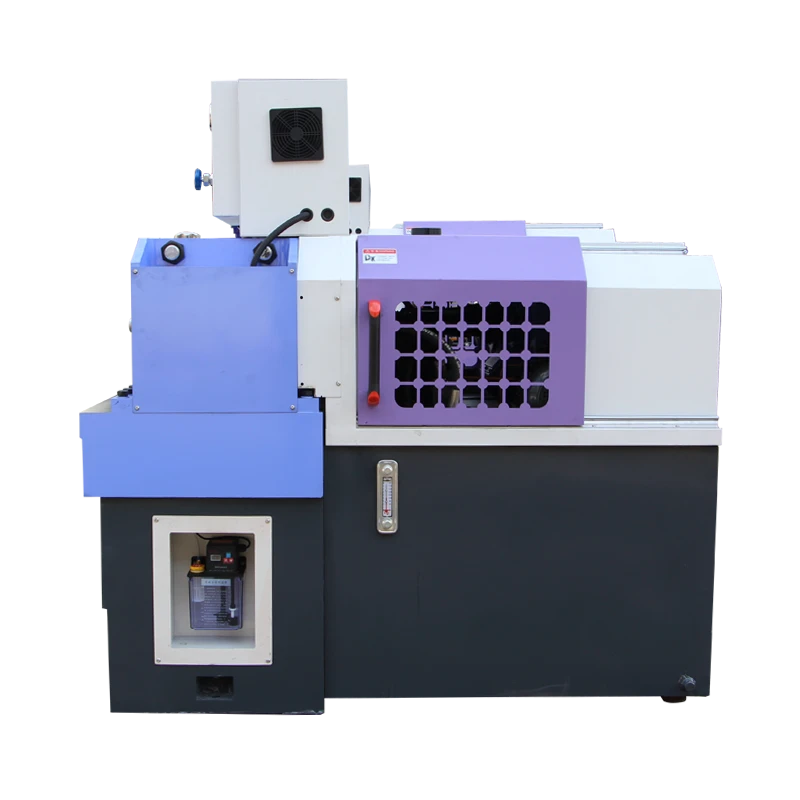

Manufacturers of Rebar Thread Rolling Machines for Enhanced Construction Efficiency

The Role and Importance of Rebar Thread Rolling Machine Factories

In the construction industry, the demand for high-quality reinforcement bars (rebars) is paramount. These steel bars are crucial for enhancing the tensile strength of concrete, ensuring structures can withstand various loads and environmental conditions. To meet these demands, innovative manufacturing processes have emerged, including the use of rebar thread rolling machines. This article explores the significance of rebar thread rolling machine factories, their production processes, and the benefits they bring to the construction sector.

Understanding Rebar Thread Rolling Machines

Rebar thread rolling machines are specialized equipment designed to cut threads onto the surface of steel reinforcement bars. This threading process allows for easy connection of rebars, which is critical when creating complex structures that require secure joints to ensure structural integrity. The rolling machines utilize specific dies to create threads that are both precise and consistent, making them essential for the production of standard and custom rebar sizes.

Manufacturing Process in Factories

The production of rebar thread rolling machines involves several critical steps, beginning with design and engineering. Factories often employ skilled engineers who design machines capable of high efficiency and durability. The selection of materials is equally important, as high-quality steel and components ensure that the machines can withstand the rigors of continuous operation.

Once the machines are designed, production begins with the fabrication of various components, which may include the machine frame, thread rolling dies, and drive systems. Advanced manufacturing techniques such as CNC machining and laser cutting are employed to enhance precision and reduce production time. Quality control is a priority at this stage, with factories implementing rigorous testing procedures to ensure that every component meets the necessary standards.

After the components are manufactured, they are assembled into the final product. This assembly process involves skilled technicians who ensure that each machine operates seamlessly. The final step involves extensive testing to verify that the machines can perform under heavy loads and continue working for long periods without failure.

rebar thread rolling machine factories

Advantages of Rebar Thread Rolling Machine Factories

1. Precision and Efficiency One of the primary advantages of rebar thread rolling machine factories is their ability to produce threaded rebars with high precision. This ensures that the rebars fit together perfectly, which is vital for maintaining the structural integrity of buildings and infrastructure.

2. Cost-Effectiveness Using thread rolling machines can significantly reduce labor costs and time associated with manually cutting threads on rebars. This efficiency helps construction companies save money and allocate resources more effectively.

3. Versatility Rebar thread rolling machines can produce various thread sizes and styles, making them suitable for different construction needs. Factories can adapt their machinery to meet specific project requirements, enhancing their competitiveness in a diverse marketplace.

4. Durability and Quality Control The manufacturing processes employed in rebar thread rolling machine factories often incorporate strict quality control measures. As a result, the machines produced are built to last, minimizing downtime and maintenance costs for users.

5. Sustainability Many factories are increasingly aware of their environmental impact and are implementing sustainable practices. This includes using energy-efficient manufacturing processes and recycling scrap materials, contributing to a greener construction industry.

Conclusion

Rebar thread rolling machine factories play a crucial role in the construction industry by providing essential equipment for producing high-quality threaded rebars. Their sophisticated manufacturing processes ensure precision, efficiency, and durability, allowing the construction sector to meet the growing demands for robust infrastructure. As the industry continues to evolve, these factories will remain at the forefront of innovation, contributing to safer and more sustainable construction practices worldwide. The importance of these machines and the factories that produce them cannot be overstated, as they are essential to building the foundations of our modern world.