-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

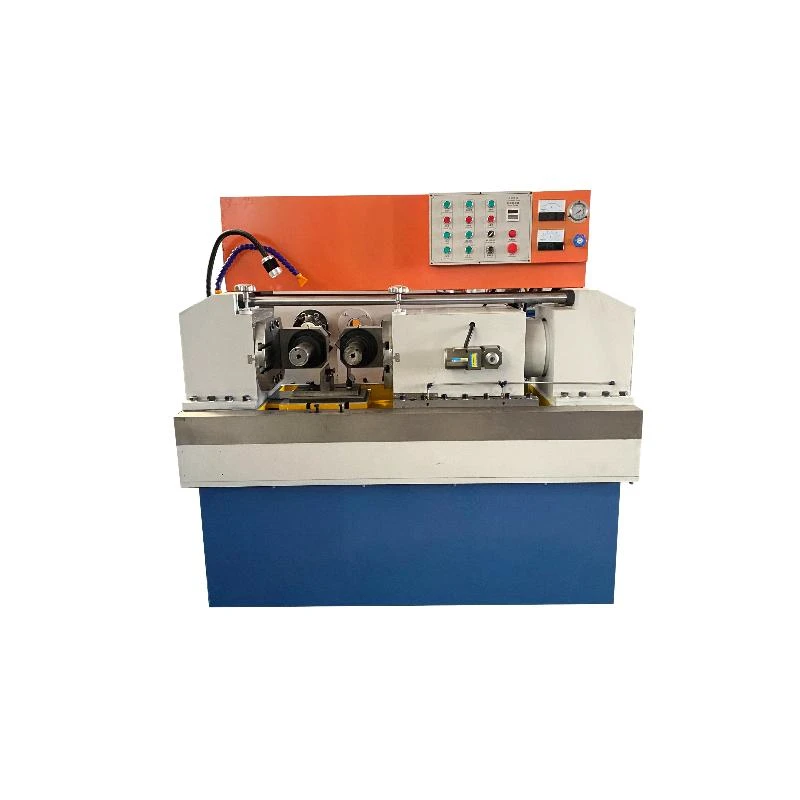

reed thread roller companies

The Importance of Reed Thread Roller Companies in Modern Manufacturing

In the world of manufacturing, precision and efficiency are paramount. One of the most critical areas where these qualities are vital is in the production of threaded components. This is where reed thread roller companies come into play, providing essential services that support a variety of industries, from automotive to aerospace. Understanding the significance of these companies and their operations can shed light on their integral role in modern production processes.

What is Thread Rolling?

Thread rolling is a process used to create threads on a workpiece. Instead of cutting the material, which can be wasteful, thread rolling deforms the material's surface to form the desired thread. This method allows for increased strength and improved surface finish compared to traditional machining methods. Reed thread rolling companies specialize in this innovative process, ensuring that the produced threads meet stringent specifications and standards required by various applications.

Reed Thread Roller Companies Overview

Reed thread roller companies are distinguished by their expertise in using specialized machinery and technology to produce threaded parts. These companies typically employ advanced machines that apply considerable pressure to the material, shaping it into the required thread form. The benefits of thread rolling over traditional cutting methods include greater material utilization, enhanced durability of the threads, and ultimately, cost efficiency in production.

Moreover, reed thread roller companies often offer customization options, allowing them to meet specific client needs

. Whether it’s a unique thread design, specific material requirements, or particular dimensions, these companies can often tailor their processes to deliver precisely what is needed.Key Benefits of Utilizing Reed Thread Roller Companies

reed thread roller companies

1. Enhanced Strength and Durability The thread rolling process improves the integrity of the material. The cold working action increases the grain density, which results in stronger threads that can withstand higher stress and pressure. This is particularly important for components that are integral to the safety and operation of vehicles or machinery.

2. Cost Efficiency By reducing material waste and minimizing the need for extensive finishing processes, thread rolling can lower production costs. Reed thread roller companies help clients save money while maintaining high standards of quality.

3. Precision and Consistency One of the key advantages of thread rolling is the ability to produce large quantities of uniform threaded components. Reed thread roller companies utilize state-of-the-art technology to ensure that each piece meets the exact specifications required by their clients, thus maintaining consistency in the production line.

4. Rapid Production Rates Thread rolling is inherently faster than traditional cutting methods. This efficiency allows manufacturers to keep up with demand, especially in industries where time-to-market is critical.

Industry Applications

The applications of products manufactured by reed thread roller companies span multiple industries. In the automotive sector, threaded components are crucial for assembly and safety systems. In aerospace, they are vital for engine components and structural assemblies that require high strength and reliability. Other industries, including construction, electronics, and consumer goods, also benefit from the precision and efficiency provided by these specialized companies.

Conclusion

Reed thread roller companies play a critical role in the manufacturing landscape by providing essential services that enhance production efficiency, reduce costs, and ensure high-quality threaded components. As industries continue to evolve and demand more advanced solutions, these companies are likely to remain at the forefront, driving innovation and supporting the development of high-performance products. Their contributions not only strengthen individual sectors but also bolster the manufacturing industry as a whole, reinforcing the idea that precision engineering is vital for technological advancement.