-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

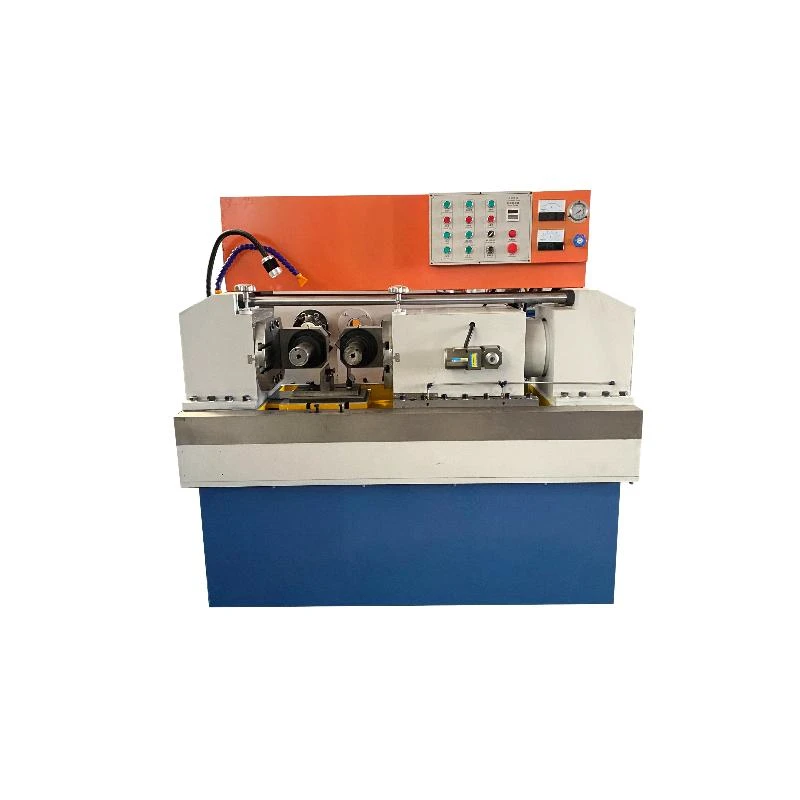

reed thread rolling machines factories

The Importance of Reed Thread Rolling Machines in Modern Manufacturing

In the rapidly evolving landscape of manufacturing, precision and efficiency have become paramount. One of the unsung heroes of this sector is the thread rolling machine, particularly those manufactured by Reed. These machines are essential for producing high-quality threaded components used in a multitude of applications, from automotive to aerospace and beyond. This article will explore the significance of Reed thread rolling machines and how they enhance production processes in factories around the world.

What is Thread Rolling?

Thread rolling is a cold-forming process that creates threads on cylindrical parts. This method utilizes hardened steel dies to press material into the desired thread form without removing any material, thus significantly reducing scrap and enhancing overall material yield. The advantages of this technique over traditional cutting methods are manifold—it improves strength due to the work hardening of the material, allows for precise dimensions, and offers a smoother surface finish.

Why Choose Reed Thread Rolling Machines?

1. Precision Engineering Reed thread rolling machines are known for their exceptional precision. The company’s advanced engineering techniques ensure that every part produced meets stringent quality specifications. This precision is crucial in industries where tolerances are tight, such as in the manufacture of bolts and nuts that must fit together flawlessly.

2. Durability and Reliability Factory environments can be harsh, and equipment must withstand continuous use. Reed machines are built to be rugged and reliable, minimizing downtime and maintenance costs. Their longevity translates to better return on investment for manufacturing firms.

3. Versatile Applications Reed thread rolling machines can handle a wide array of materials and thread types, making them suitable for diverse industries. From producing simple fasteners to complex components, these machines are versatile enough to adapt to a factory's changing needs.

4. Increased Efficiency Speed is of the essence in production lines. Reed machines are designed to roll threads quickly while maintaining quality, which maximizes output. With faster cycle times than traditional machining processes, manufacturers can significantly boost their production rates.

reed thread rolling machines factories

5. Cost-Effectiveness By employing thread rolling machines, factories can reduce operational costs. The minimized material waste, lower energy consumption during the cold-forming process, and decreased need for secondary operations all contribute to a more economical production process.

Innovations in Thread Rolling Technology

Reed continuously innovates to stay at the forefront of thread rolling technology. Recent advancements include automation features that integrate with Industry 4.0 practices, allowing for smarter production lines where machines can communicate and respond in real-time to changing conditions. This leads to enhanced productivity and reduced error rates.

Moreover, improvements in precision die technology enable Reed machines to handle increasingly complex designs that were once deemed unfeasible with traditional methods. This evolution is critical, especially as industries evolve towards more intricate and efficient designs.

The Role of Thread Rolling in Sustainability

The growing emphasis on sustainability within manufacturing cannot be overlooked. Thread rolling processes utilized by Reed machines generate significantly less waste than traditional cutting methods. By maximizing material usage and minimizing energy consumption, these machines contribute to a more sustainable manufacturing model.

Conclusion

In conclusion, Reed thread rolling machines play a crucial role in modern manufacturing by providing a reliable, efficient, and cost-effective means to produce high-quality threaded components. Their combination of precision engineering, durability, and innovative technology makes them a valuable asset for factories aiming to enhance production while maintaining sustainability. As industries continue to evolve, the demand for advanced manufacturing solutions like those offered by Reed will undoubtedly grow, solidifying the importance of these machines in the production landscape. Whether in automotive, aerospace, or any other sector, the commitment to quality and efficiency represented by Reed thread rolling machines ensures that they will remain central to the future of manufacturing.