-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

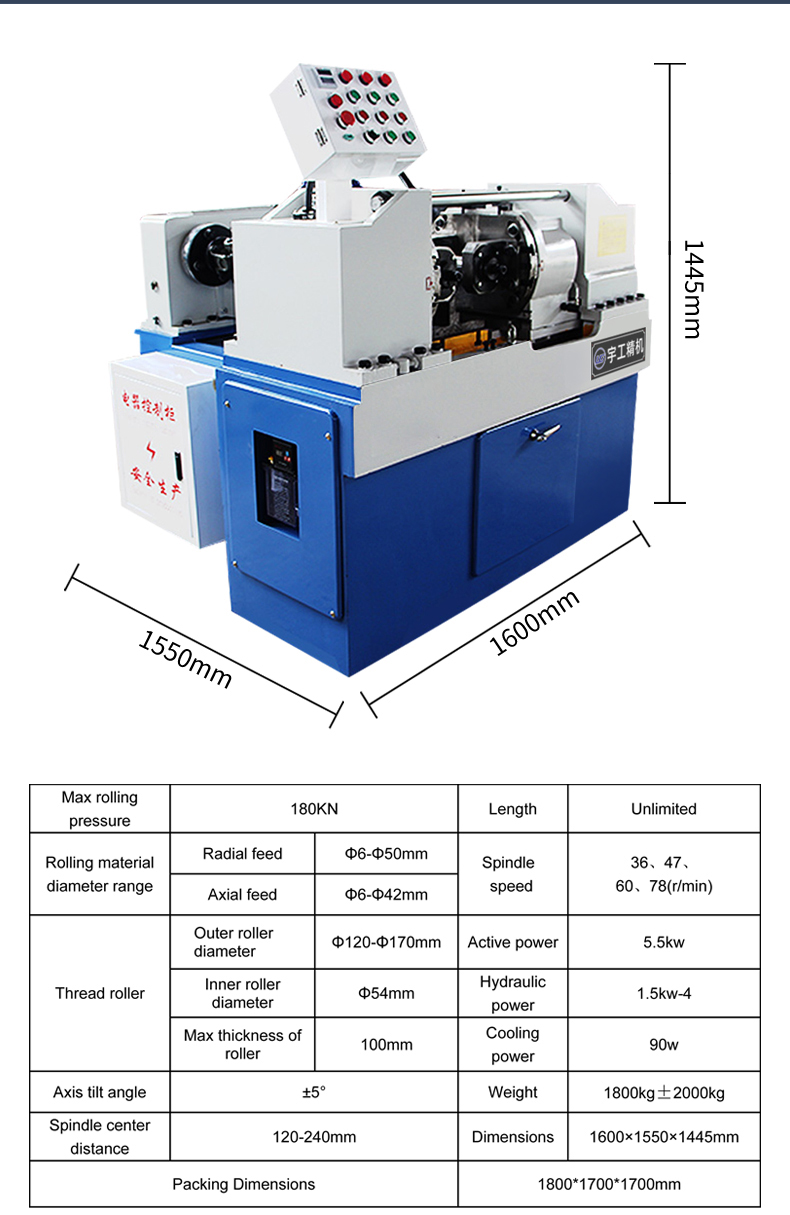

reed thread rolling machines products

Reed Thread Rolling Machines Revolutionizing Manufacturing Precision

In the fast-paced world of manufacturing, efficiency and precision are paramount. Among the myriad of machines that facilitate production, thread rolling machines stand out as vital equipment in creating high-quality threaded fasteners and components. One notable player in this arena is Reed, a company renowned for its innovative thread rolling machines that cater to diverse industrial needs.

Understanding Thread Rolling Machines

Thread rolling is a cold forming process that uses rotary dies to create threads on a workpiece. This method is highly efficient and produces superior quality threads compared to traditional machining methods. As the workpiece is fed between two parallel dies, it undergoes deformation, resulting in an increase in thread density and strength. The outcome is a robust and precise thread, which is crucial in industries such as automotive, aerospace, and construction.

Reed's Innovative Solutions

Reed has established itself as a leader in the design and manufacture of thread rolling machines. Their products are known for their reliability, precision, and state-of-the-art technology. Reed offers a range of thread rolling machines, including single and multiple die configurations, which cater to varying production needs.

One of the standout features of Reed's machines is their ability to operate at high speeds while maintaining excellent dimensional accuracy. This efficiency is crucial for high-volume production settings where time and precision are interconnected. The machines are also engineered to reduce waste, as the thread rolling process requires minimal material removal compared to cutting processes, leading to cost-effective production.

Applications Across Industries

reed thread rolling machines products

The versatility of Reed's thread rolling machines makes them suitable for various applications. In the automotive industry, for example, they are used to manufacture components such as bolts, nuts, and screws that require precise threading to ensure secure assemblies. Similarly, the aerospace sector relies on high-strength fasteners produced through thread rolling to withstand extreme conditions.

Additionally, Reed's machines are prevalent in the manufacturing of fasteners used in construction and heavy machinery, where durability and reliability are non-negotiable. The technology employed by Reed not only enhances productivity but also ensures that the end products meet stringent quality standards.

Customer-Centric Approach

What sets Reed apart in a competitive market is its commitment to customer satisfaction. The company emphasizes understanding the specific needs of its clients, allowing for customized solutions that enhance the production process. Reed’s support extends beyond the sale of machines; their team of experts provides guidance on machine maintenance and optimization, ensuring that clients maximize their operational efficiency.

Sustainability and Future Innovations

In an era where sustainability is crucial, Reed is also making strides toward more eco-friendly manufacturing processes. Their machines are designed with energy efficiency in mind, reducing the carbon footprint of production operations. As the industry evolves, Reed is poised to integrate advanced technologies such as automation and artificial intelligence into their machines, further enhancing productivity and precision.

Conclusion

Reed thread rolling machines exemplify the intersection of precision engineering and innovative manufacturing solutions. Their ability to produce high-quality threaded components with efficiency and reliability underscores their importance in various industries. As manufacturing continues to evolve, Reed remains dedicated to pushing the boundaries of technology while ensuring customer satisfaction and sustainability. Investing in Reed thread rolling machines is not merely a decision about equipment; it is a step toward embracing the future of manufacturing excellence.